Automatic gas source distributor with safety function

A technology of automatic distributor and safety function, which is applied in the direction of gas/liquid distribution and storage, safety valve, function valve type, etc. It can solve the problems of mutual influence of safety valves, inaccurate pressure regulation, hidden safety hazards, etc., and achieve simple pipeline , Reduce energy waste and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

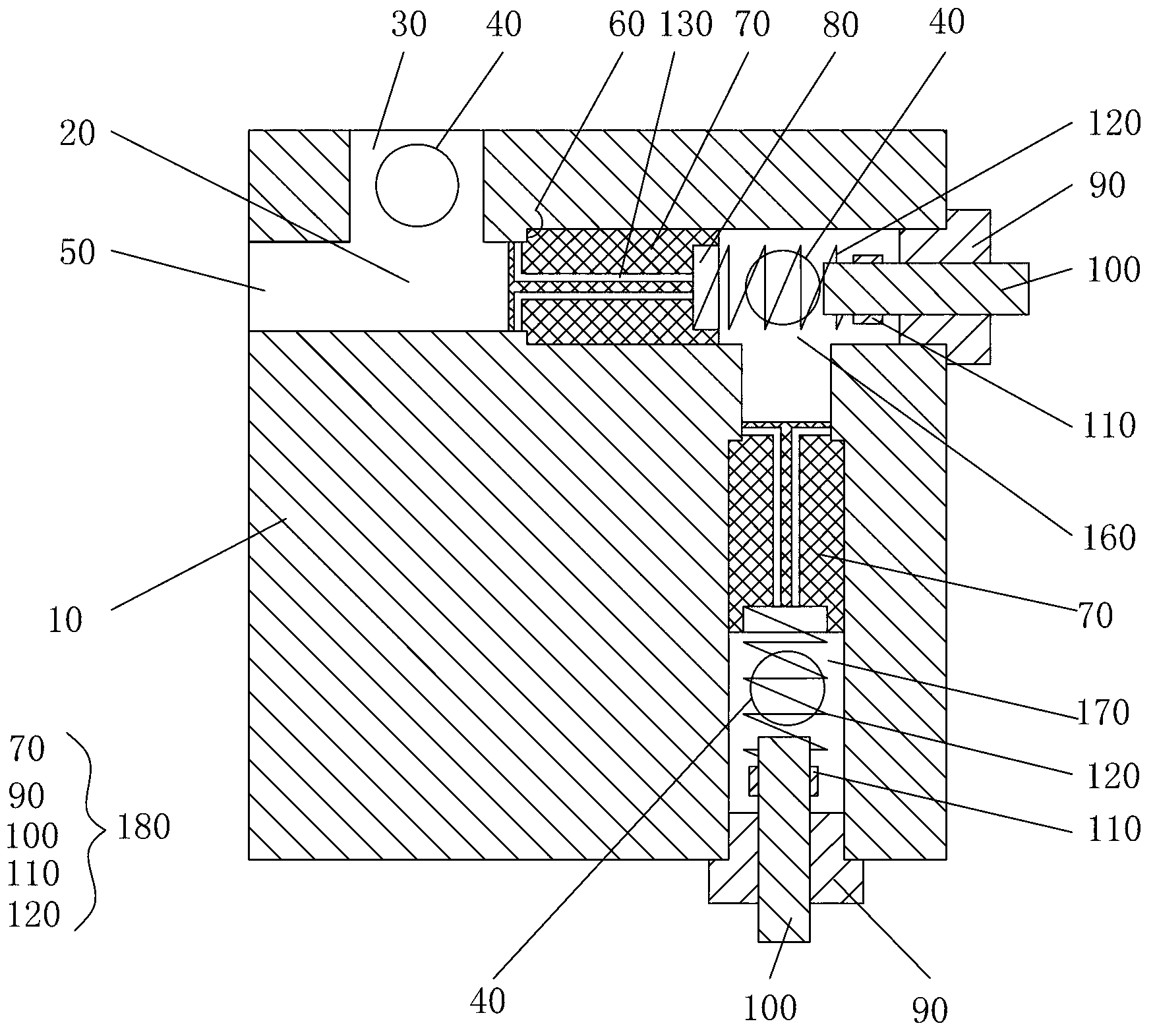

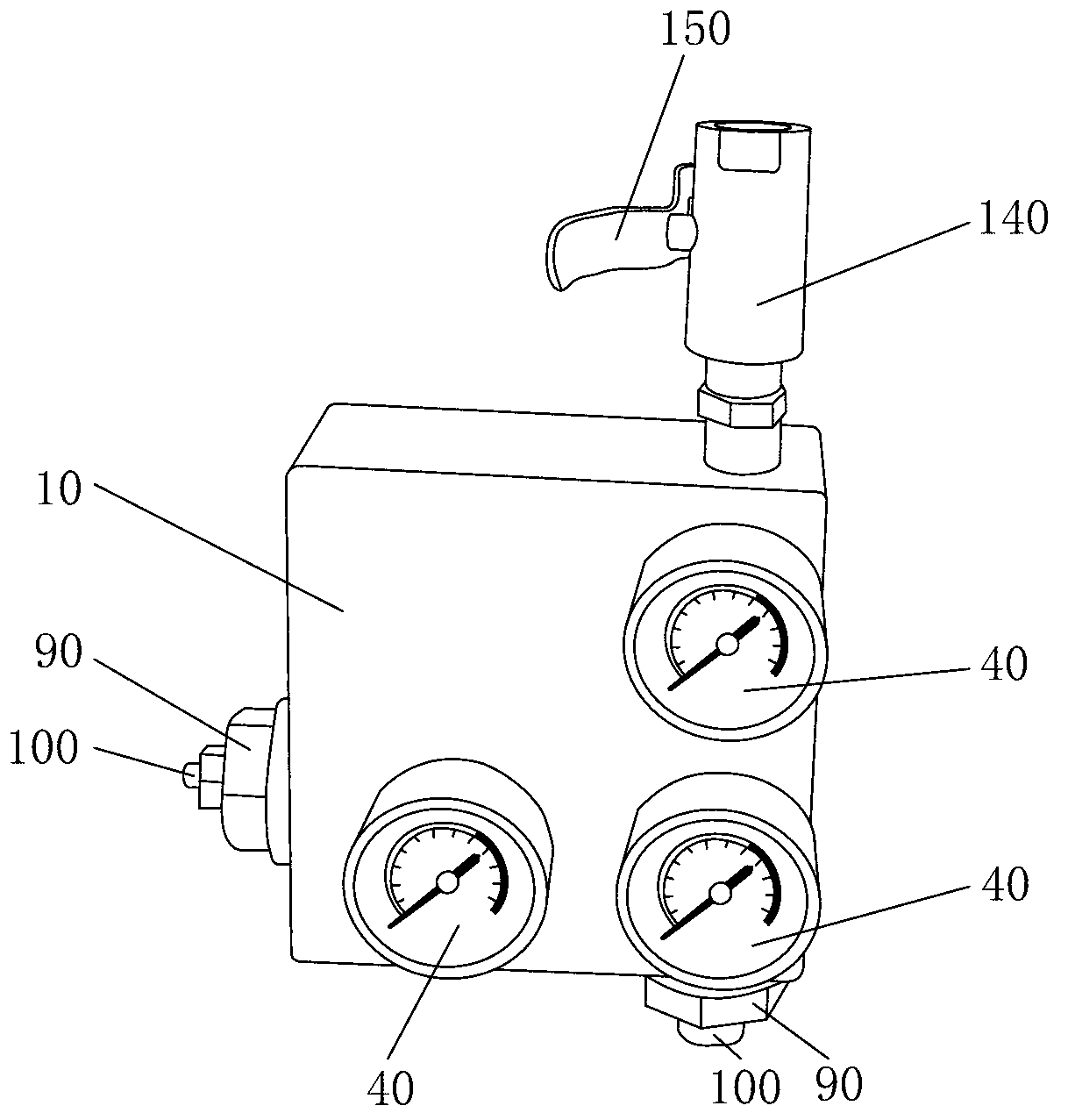

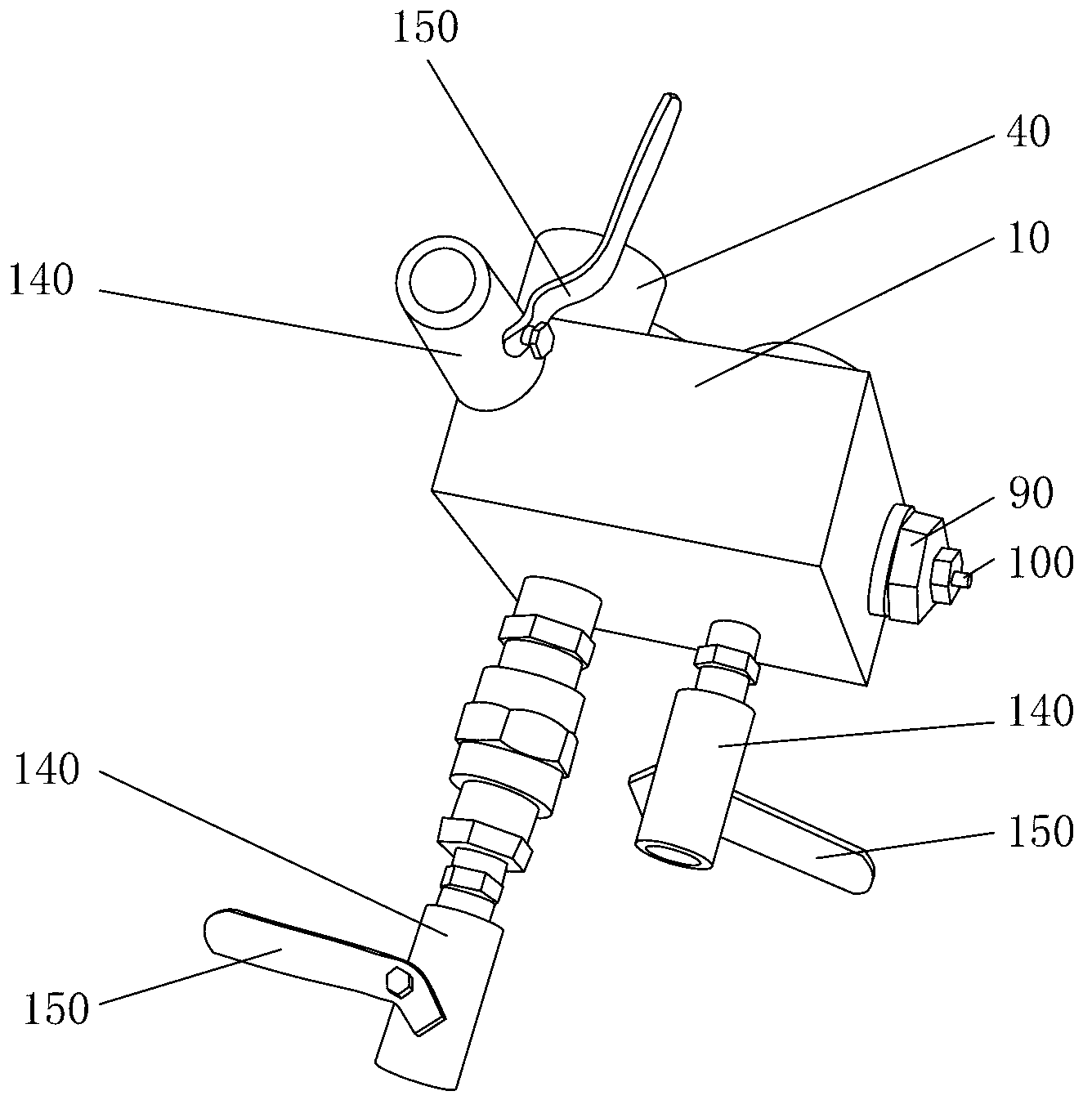

[0020] The present invention will be further described below with specific embodiment, see figure 1 —3:

[0021] An automatic gas source distributor with safety function, the distributor body 10 is provided with more than two pressure chambers whose pressures decrease successively, the pressure of the former pressure chamber is diverted to the latter pressure chamber, and the adjacent two A safety valve 180 is provided between the pressure chambers of each stage, and an output pipe for outputting pressure to the outside is provided on each stage of the pressure chamber, and an input pipe 30 connected with a gas source is communicated with the first-stage pressure chamber 20 .

[0022] Each of the above-mentioned pressure chambers is provided with a pressure gauge 40 for detecting the pressure in the pressure chamber.

[0023] The above-mentioned two-stage or more pressure chambers are formed by more than one pipeline, and each pipeline communicates with each other. The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com