Heat supply network water circulating pump energy-saving driving system of thermal power plant

A technology for a water circulation pump and a drive system, which is applied in the field of thermal coal-fired power generation and heating units, can solve the problems of not saving energy, and the energy saving effect is not obvious, and achieve the effects of saving power consumption, small project investment risks, and low maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

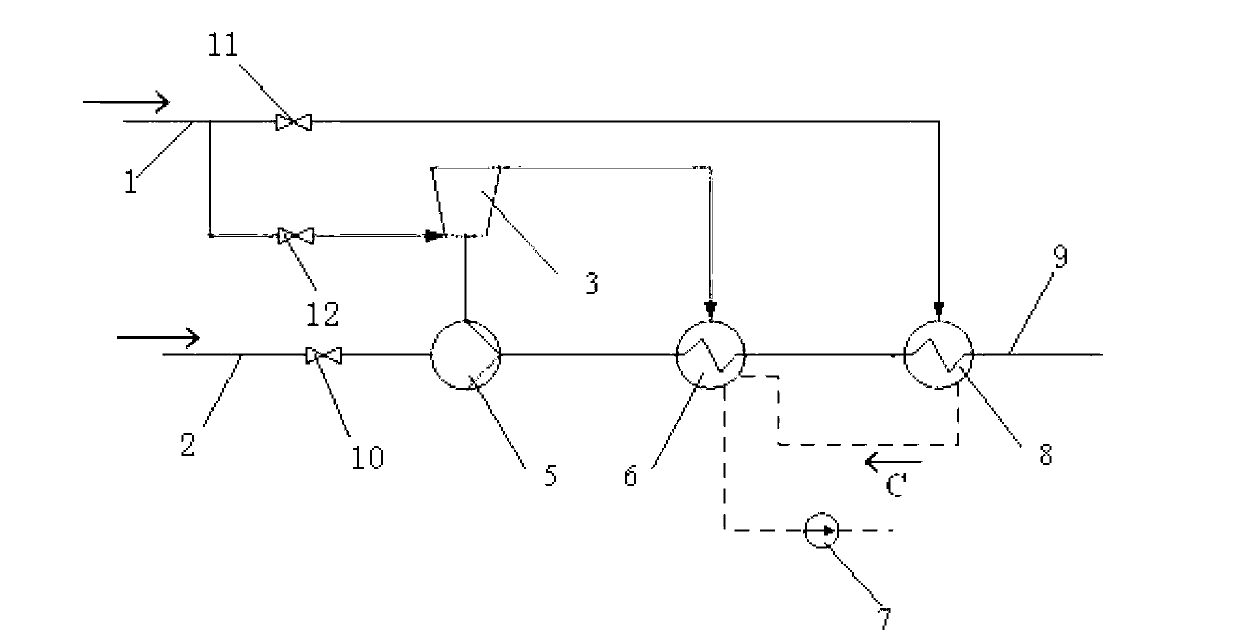

[0018] Embodiment 1: as figure 1 As shown, the energy-saving driving system of the heat network water circulation pump of the thermal power plant in this embodiment consists of a steam inlet pipe 1, a secondary inlet valve 11, a steam turbine inlet valve 12, a circulating water inlet pipe 2, a circulating water valve 10, a steam turbine 3, and a heat network Circulating pump 5, primary heating network heater 6, drain pump 7, secondary heating network heater 8, circulating water outlet pipe 9 and corresponding connecting pipelines.

[0019] The heating steam is divided into two paths in the steam inlet pipe 1, one path is supplied to the steam turbine 3, and the other path directly heats the circulating water of the heating network through the second-stage heat network heater 8, and the steam turbine inlet valve 12 and the second stage are respectively installed on the two paths. Stage intake valve 11. The circulating water of the heating network passes through the circulating...

Embodiment 2

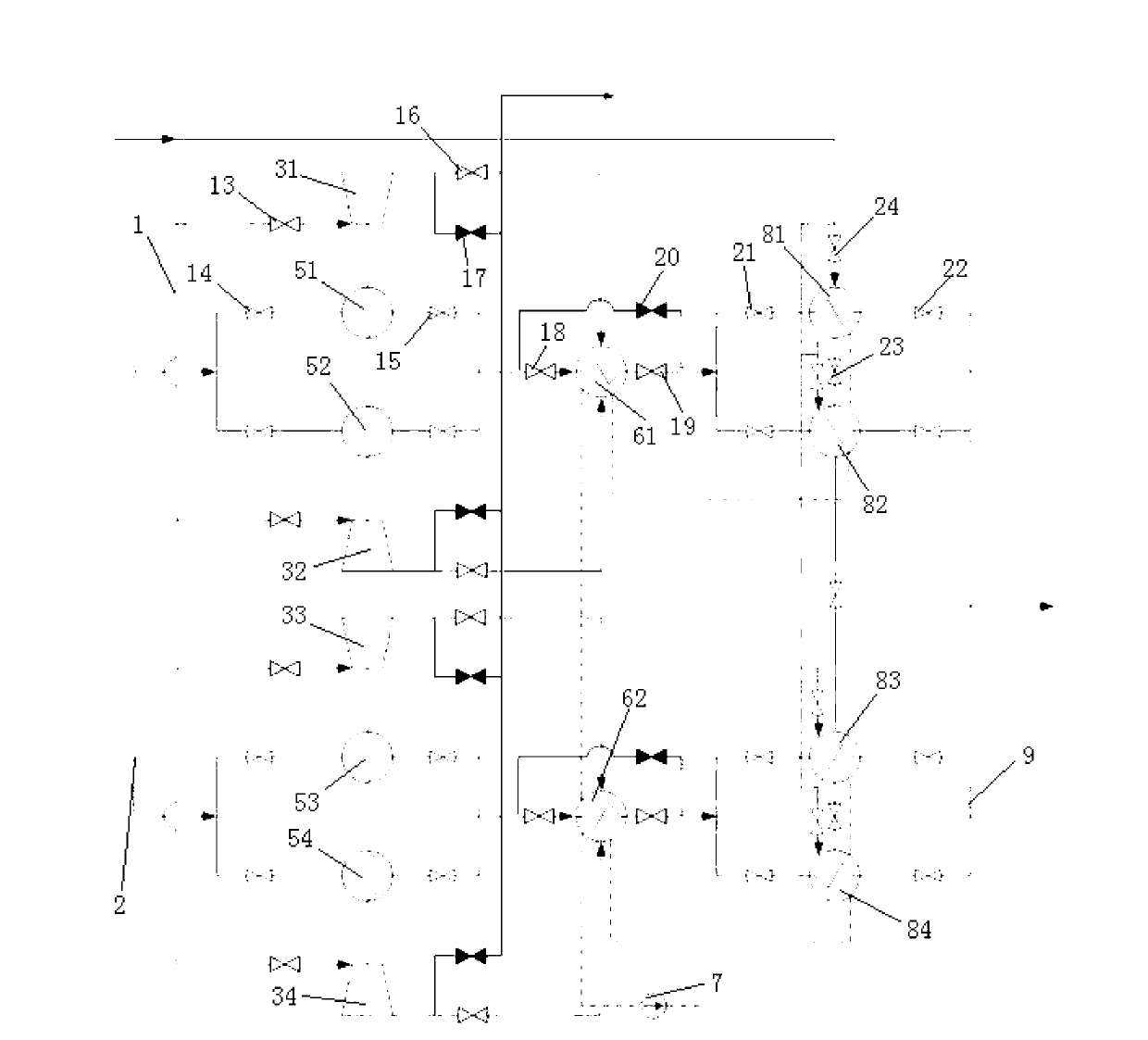

[0021] Embodiment 2: as figure 2 As shown, the energy-saving driving system of the heat network water circulation pump of the thermal power plant in this embodiment consists of a steam inlet pipe 1, a circulating water inlet pipe 2, a drain pump 7, a steam turbine inlet valve 13, a circulating water valve 14 before the circulating pump, and a circulating water after the circulating pump. Valve 15, steam turbine exhaust valve 16, steam turbine exhaust steam backup valve 17, primary heating network heater front circulating water valve 18, primary heating network heater rear circulating water valve 19, primary heating network heater bypass valve 20 , Secondary heating network heater front circulating water valve 21, Secondary heating network heater rear circulating water valve 22, Secondary heating network heater Unicom valve 23, Secondary heating network heater steam inlet valve 24, No. 1 steam turbine 31 , No. 2 steam turbine 32, No. 3 steam turbine 33, No. 4 steam turbine 34,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap