Air dehumidification unit and process

An air dehumidification and air technology, applied in space heating and ventilation, space heating and ventilation details, heating methods, etc., can solve the problem of uneven heating of the inner wall of the hose, narrowing the diameter of the hose, and reducing the internal volume of the hose And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

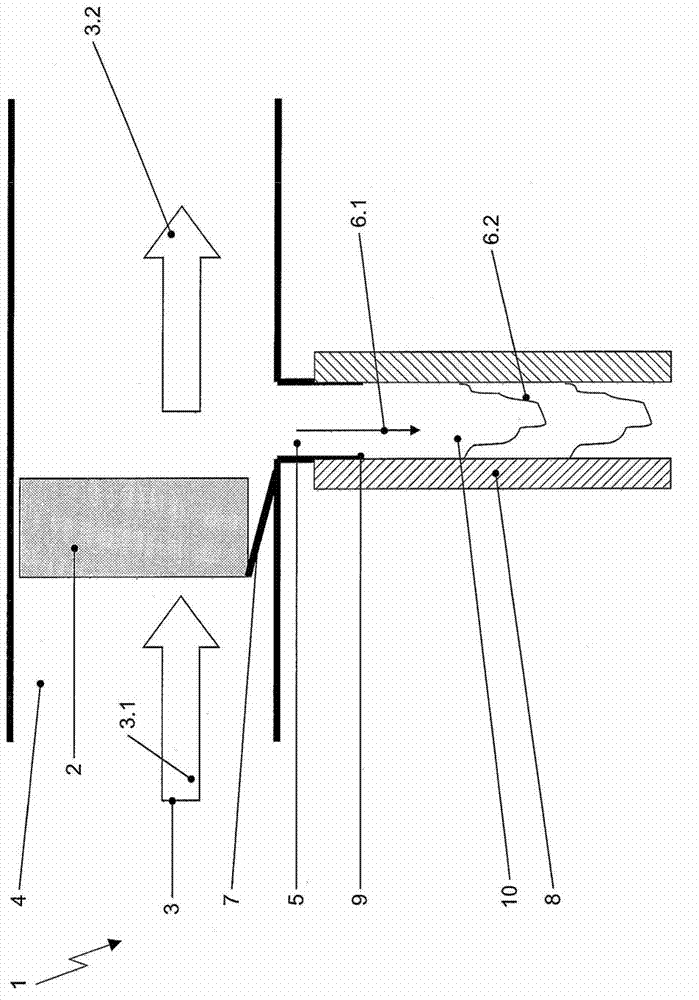

[0026] figure 1 A section is shown of a motor vehicle HVAC system with an air dehumidification unit 1 in the region of the evaporator 2 for supplying heat from the air to be conditioned 3.1 inside the vehicle to the refrigerant of the heat pump system. The evaporator 2 is located in the air flow channel 4 , so that the incoming fresh air 3 . 1 or recirculation air 3 . 1 has to pass through the evaporator 2 . The air 3.1 to be conditioned passes through the evaporator 2, for example at a temperature of 15° C. and a relative humidity of 80%, after passing through the evaporator 2 the dehumidified air has, for example, a relative humidity of 97% and a temperature of 3° C. In the region of the gas flow channel 4 downstream of the evaporator 2 , a vertically (vertical) oriented condensate drain channel 5 is arranged so that the liquid condensate 6 . 1 can flow downwards. A condensate drain channel 5 (drain) is provided for draining of the HVAC system. about figure 1 In the illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com