Roller dryer with discharging conveying device

A conveying device and a drum-type technology, applied in the field of dryers and drum-type dryers, can solve the problems of uncontrollable material outflow speed and drying humidity, difficulty in maintaining stable and consistent drying quality, and rework of unqualified products. The hot air is in full contact with the material, the quality and speed of the discharge are controllable, and the quality of the discharge is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

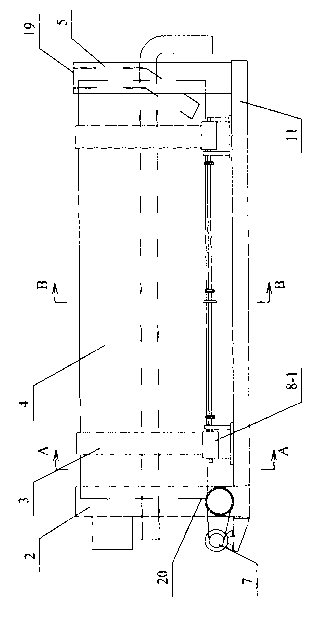

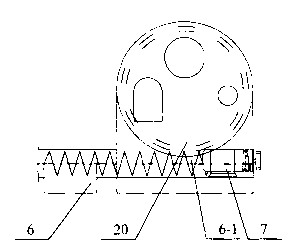

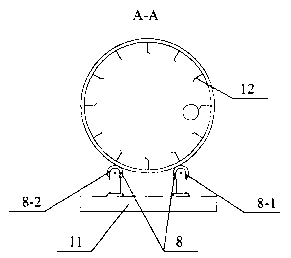

[0020] Such as Figure 1~4 As shown, a tumble dryer includes a cylinder body 4 , a tail cover 2 , a head cover 5 , a frame 11 and a power mechanism 13 , and a screw conveyor 6 with a discharge power 7 . Head cover 5 and tail cover 2 are positioned at the two ends of cylinder 4, cylinder body 4 is the cylinder 4 of inclination, and head cover 5 is positioned at the high end of tilt cylinder 4, and tail cover 2 is positioned at the low end of tilt cylinder 4. The power mechanism 13 is connected with the drum 4 through the roller 8, and the power mechanism 13 drives the drum 4 to rotate. The high end of the drum 4 is provided with a material inlet 19 and a hot air inlet, and the low end of the drum 4 is provided with a material outlet 20 and a hot air outlet. A material outlet 20 is provided at the end. Cylindrical body 4, tail end cover 2, head cover 5 are all installed on the frame 11. The material plate 12 is fixedly connected to the inner circumference of the drum 4 . Bac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap