Shell-tube heat exchanger of coiled heat exchanging pipe

A shell-and-tube heat exchanger and heat exchange tube technology, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. The effect of convenience and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

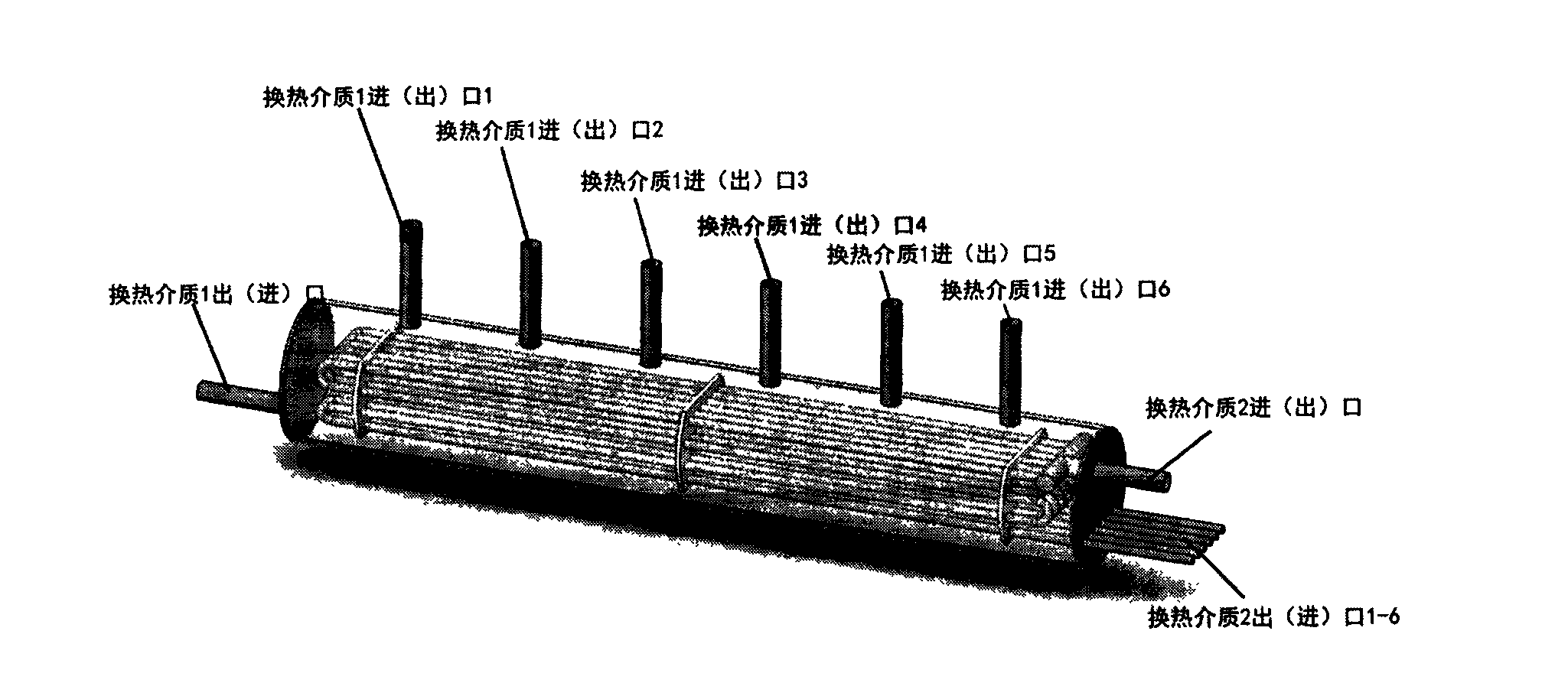

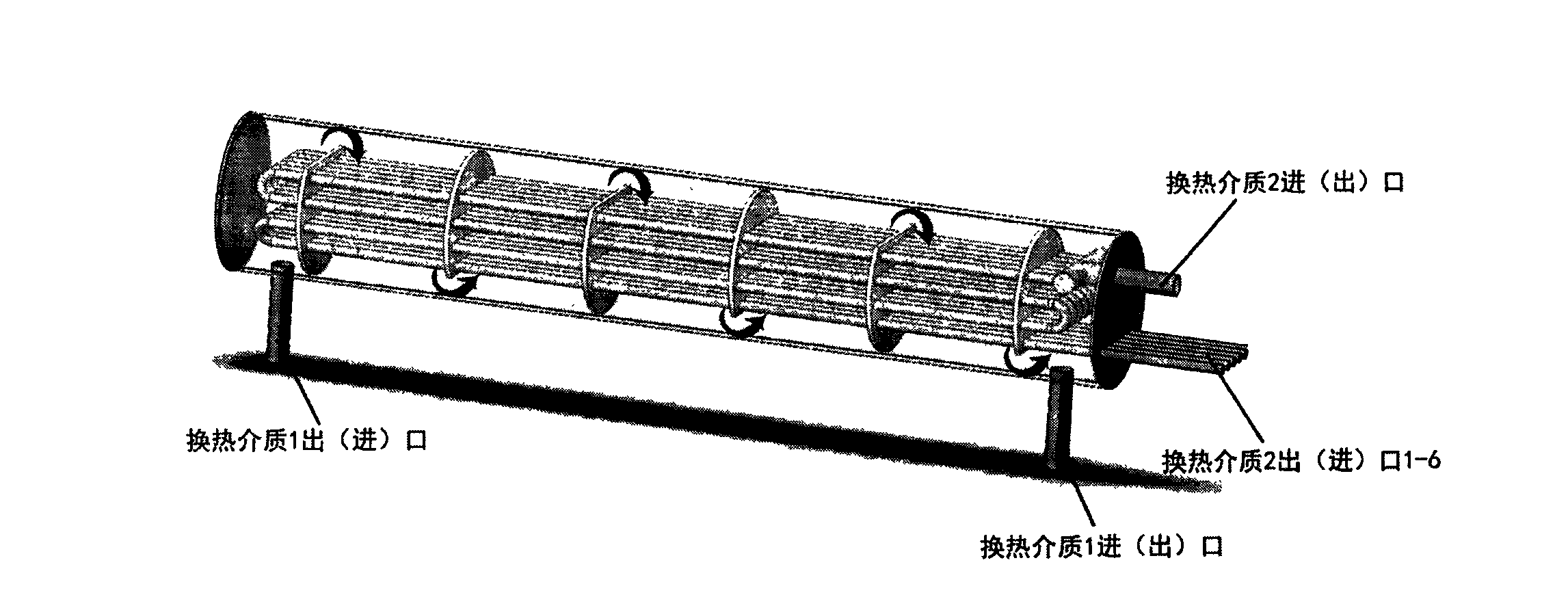

[0018] see figure 1 , there are 6 working medium 1 inlets 1-6 and 1 working medium 1 outlet on the tube wall of the shell-and-tube heat exchanger. There are 6 sets of serpentine heat exchange tubes in the shell-and-tube shell, and each set of serpentine The heat exchange tubes are 3 continuous U-shaped bending heat exchange tubes, and 6 sets of serpentine heat exchange tubes are provided with working fluid 2 outlets 1-6, a total of 6 working fluid 2 outlets, and a total of 1 working fluid 2 inlets, on the end cover of the shell-and-tube shell. Among them, the inlet of working medium 2 is shunted to the inlets of 6 sets of serpentine heat exchange tubes through pipes in the shell-and-tube shell. The heat pipe is fixed in the shell-and-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap