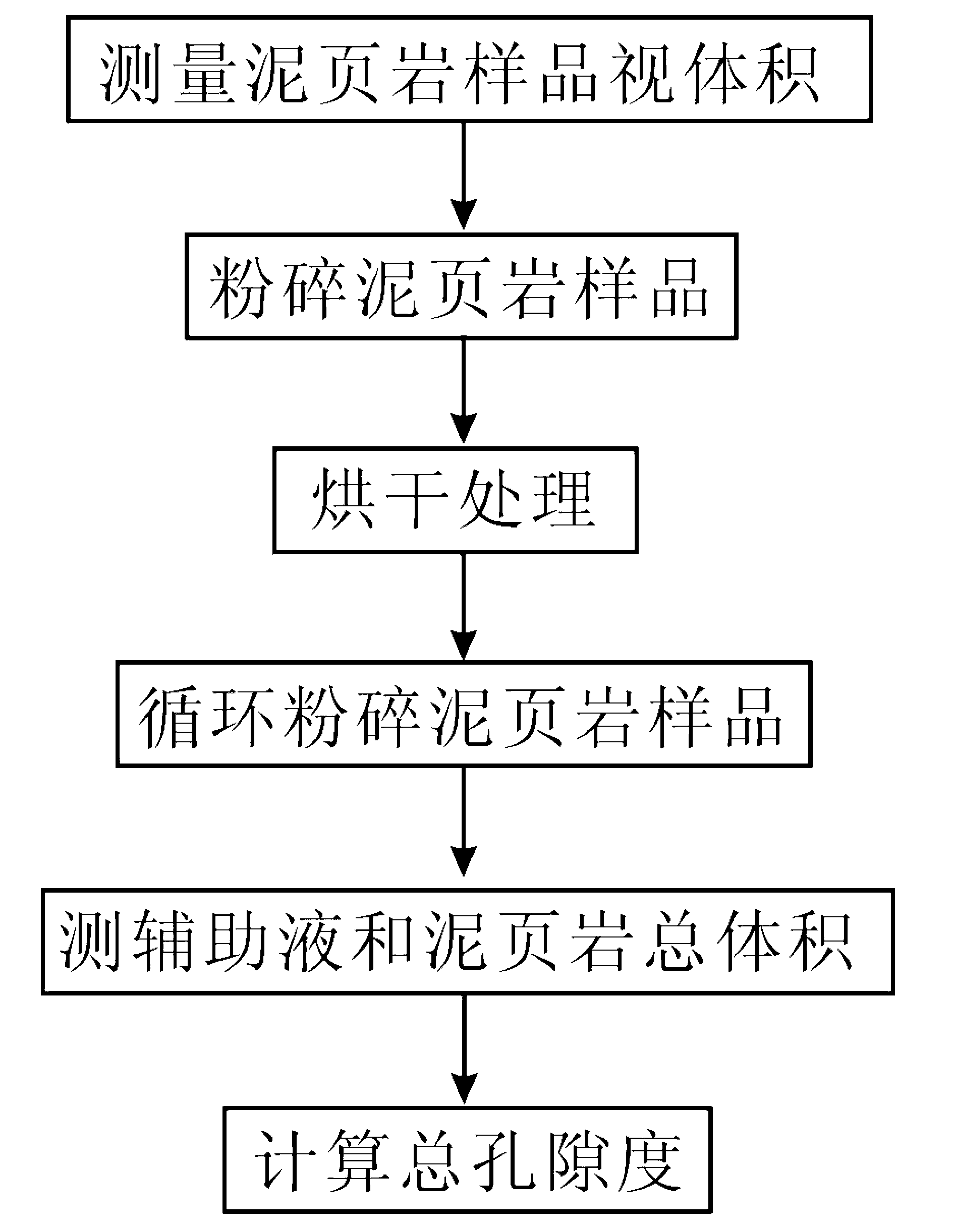

Method for measuring total porosity of shale

A technology of total porosity and shale, applied in mining exploration and development, geology, and petroleum fields, to achieve the effect of low cost, simple operation and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Taking the method of measuring the total porosity of mud shale once as an example, the present invention is further described in detail.

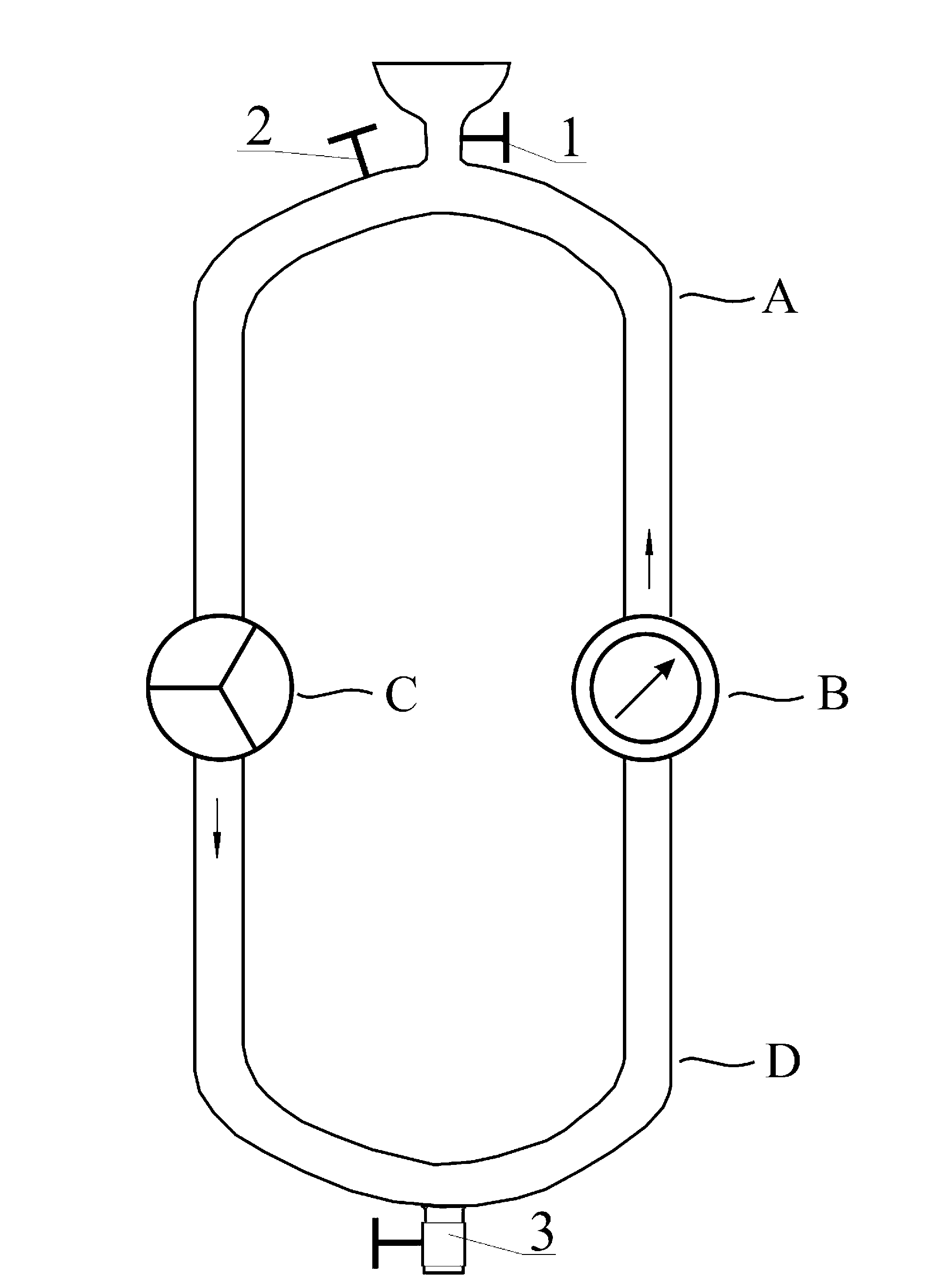

[0025] refer to figure 2 . The circulating crushing device includes a first valve (1), a second valve (2), a third valve (3), an upper U-shaped glass tube A, a lower U-shaped glass tube D, a small pulverizer (B) and a small pump (C ). The model of small pulverizer B is ZM 200; the model of small pump C is WT3000-1JA.

[0026] The inner diameter of the upper U-shaped glass tube A and the lower U-shaped glass tube D is 40 mm. The U-shaped openings of the upper U-shaped glass tube A and the lower U-shaped glass tube D are opposite to each other; one port of the upper U-shaped glass tube (A) is connected with the discharge port of the small pulverizer (B) through a rubber hose, and the small pulverizer The feeding port of the machine (B) is connected with one port of the lower U-shaped glass tube D through a rubber hos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com