Fluorinated structured organic film photoreceptor layers

An organic thin film, structural technology, applied in the field of fluorinated structural organic thin film photosensitive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

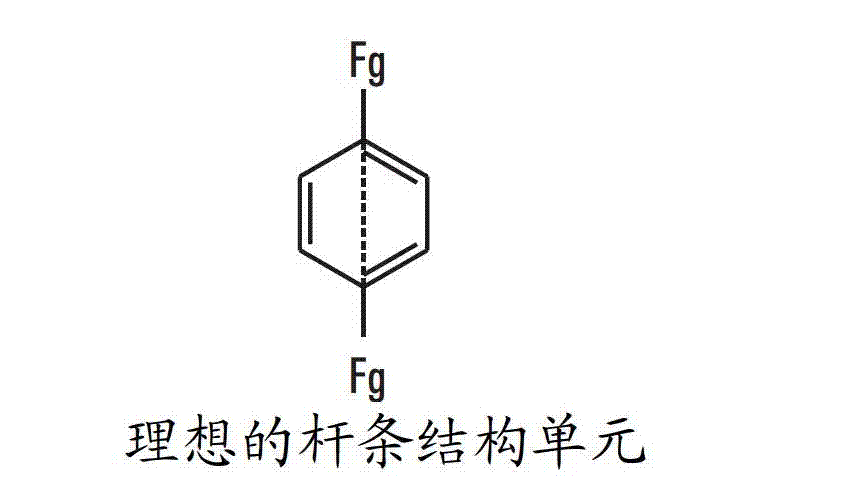

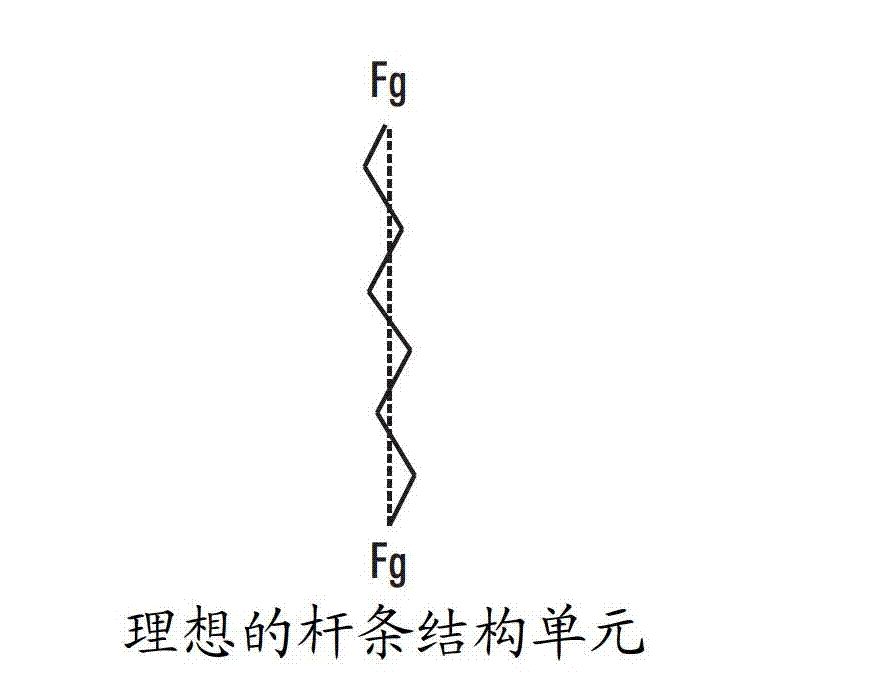

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0352] (Operation A) A liquid containing a reaction mixture is prepared. The following components were combined: structural unit octafluoro-1,6-hexanediol [segment = octafluoro-1,6-hexyl; Fg = hydroxyl (-OH); (0.43 g, 1.65 mmol)], second Structural unit N4, N4, N4', N4'-tetrakis (4-(methoxymethyl) phenyl) biphenyl-4,4'-diamine [segment = N4, N4, N4', N4' -Tetra-p-tolylbiphenyl-4,4'-diamine; Fg = methoxy ether (-OCH3); (0.55g, 0.82mmol)], in order to generate a liquid containing the reaction mixture with 0.05g of 20 Acid catalyst delivered as a wt % Nacure XP-357 solution, leveling additive delivered as 0.04 g of a 25 wt % Silclean 3700 solution and 2.96 g of 1-methoxy-2-propanol. The mixture was shaken, heated at 85°C for 2.5 hours, and then filtered through a 0.45 micron PTFE membrane.

[0353] (Run B) The reaction mixture was deposited as a wet film. The reaction mixture was coated on metallized (TiZr) MYLAR using a constant speed down-draw coater equipped with a 10 mil g...

Embodiment 2

[0356] (Operation A) A liquid containing a reaction mixture is prepared. The following components were combined: structural unit dodecafluoro-1,8-octanediol [segment = dodecafluoro-1,8-octyl; Fg = hydroxyl (-OH); (0.51 g, 1.41 mmol)] , the second structural unit N4, N4, N4', N4'-tetrakis (4-(methoxymethyl) phenyl) biphenyl-4,4'-diamine [segment=N4, N4, N4' , N4'-tetra-p-tolylbiphenyl-4,4'-diamine; Fg=methoxy ether (-OCH3); (0.47g, 0.71mmol)], in order to generate the liquid containing the reaction mixture with 0.05 g of acid catalyst delivered as a 20 wt% solution of Nacure XP-357, leveling additive delivered as 0.04 g of a 25 wt% solution of Silclean 3700, and 2.96 g of 1-methoxy-2-propanol. The mixture was shaken, heated at 85°C for 2.5 hours, and then filtered through a 0.45 micron PTFE membrane.

[0357] (Run B) The reaction mixture was deposited as a wet film. The reaction mixture was coated on metallized (TiZr) MYLAR using a constant speed down-draw coater equipped wi...

Embodiment 3

[0360] (Operation A) A liquid containing a reaction mixture is prepared. The following components were combined: structural unit hexadecafluoro-1,10-decanediol [segment = hexadecafluoro-1,10-decyl; Fg = hydroxyl (-OH); (0.57 g, 1.23 mmol)] , the second structural unit N4, N4, N4', N4'-tetrakis (4-(methoxymethyl) phenyl) biphenyl-4,4'-diamine [segment = N4, N4, N4' , N4'-tetra-p-tolylbiphenyl-4,4'-diamine; Fg=methoxy ether (-OCH 3 ); (0.41 g, 0.62 mmol)], acid catalyst delivered as 0.05 g of a 20 wt % Nacure XP-357 solution, 0.04 g of a 25 wt % Silclean 3700 solution to generate a liquid containing the reaction mixture Leveling additive and 2.96 g of 1-methoxy-2-propanol were delivered. The mixture was shaken, heated at 85°C for 2.5 hours, and then filtered through a 0.45 micron PTFE membrane.

[0361] (Run B) The reaction mixture was deposited as a wet film. The reaction mixture was coated on metallized (TiZr) MYLAR using a constant speed down-draw coater equipped with a 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com