Organic light-emitting display with glass material packaging body and manufacturing method thereof

A light-emitting display and packaging technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as difficult operation, easy cracking of substrates, increased diffusion range over time, etc., to achieve enhanced resistance to external forces Impact ability, effect of cushioning cutting stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0047] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

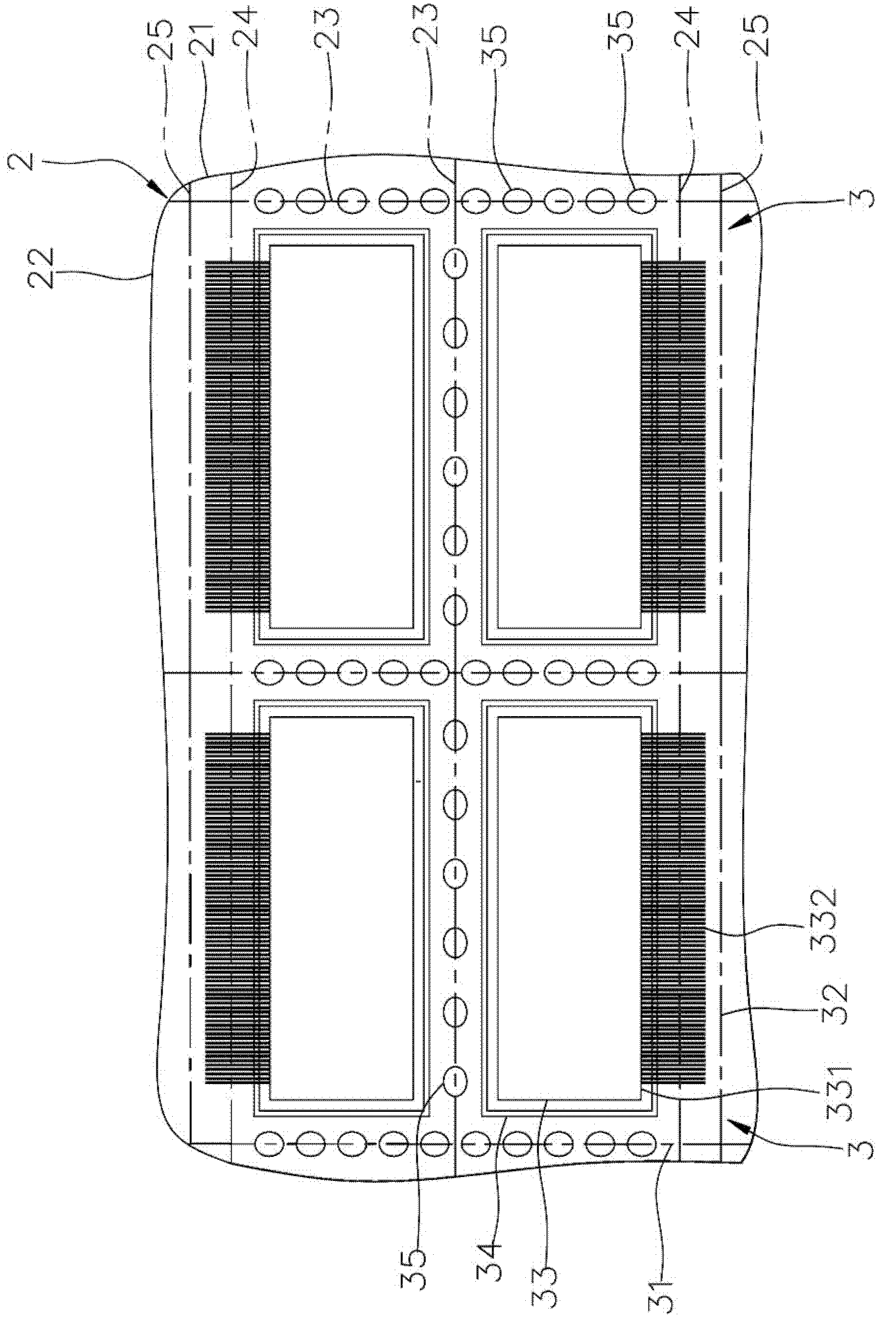

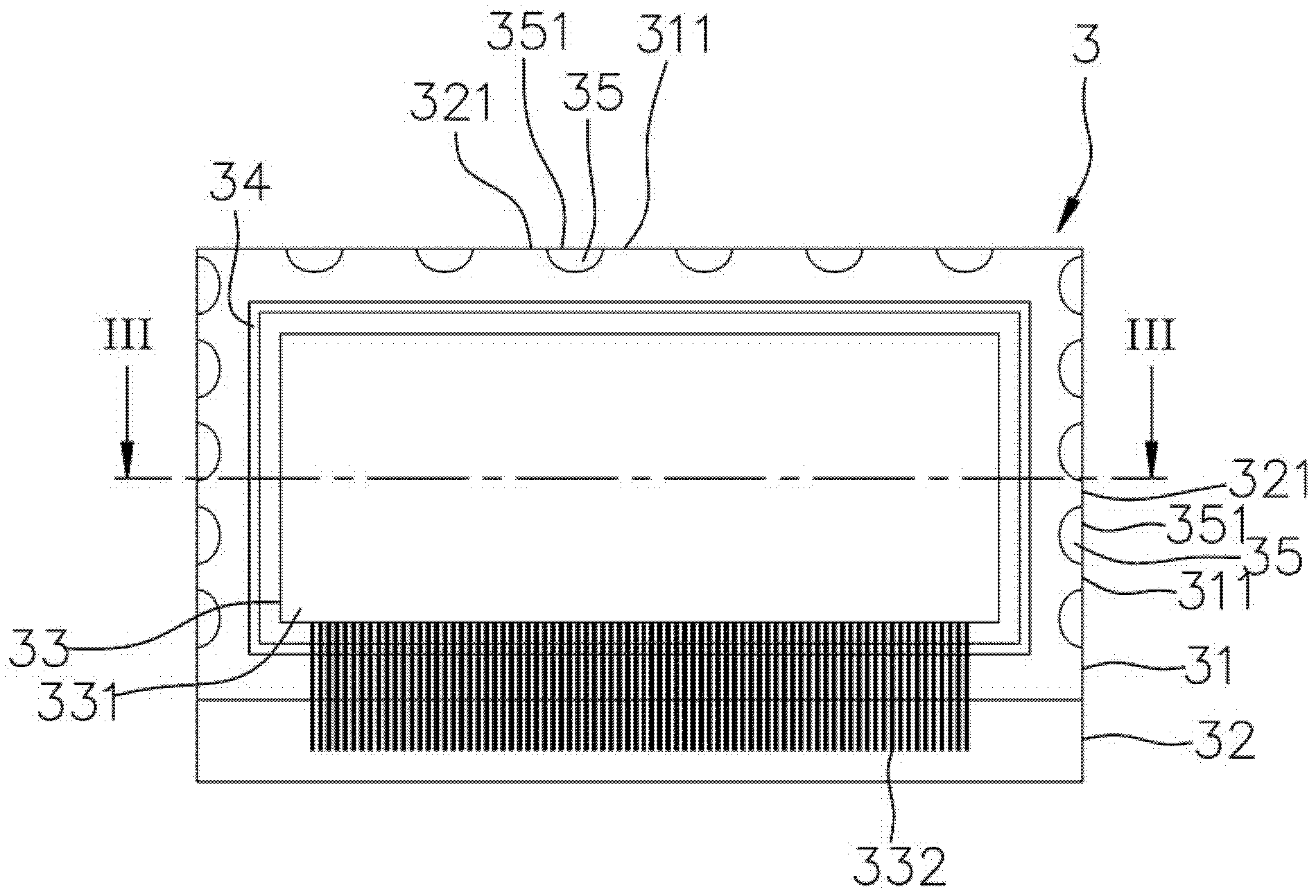

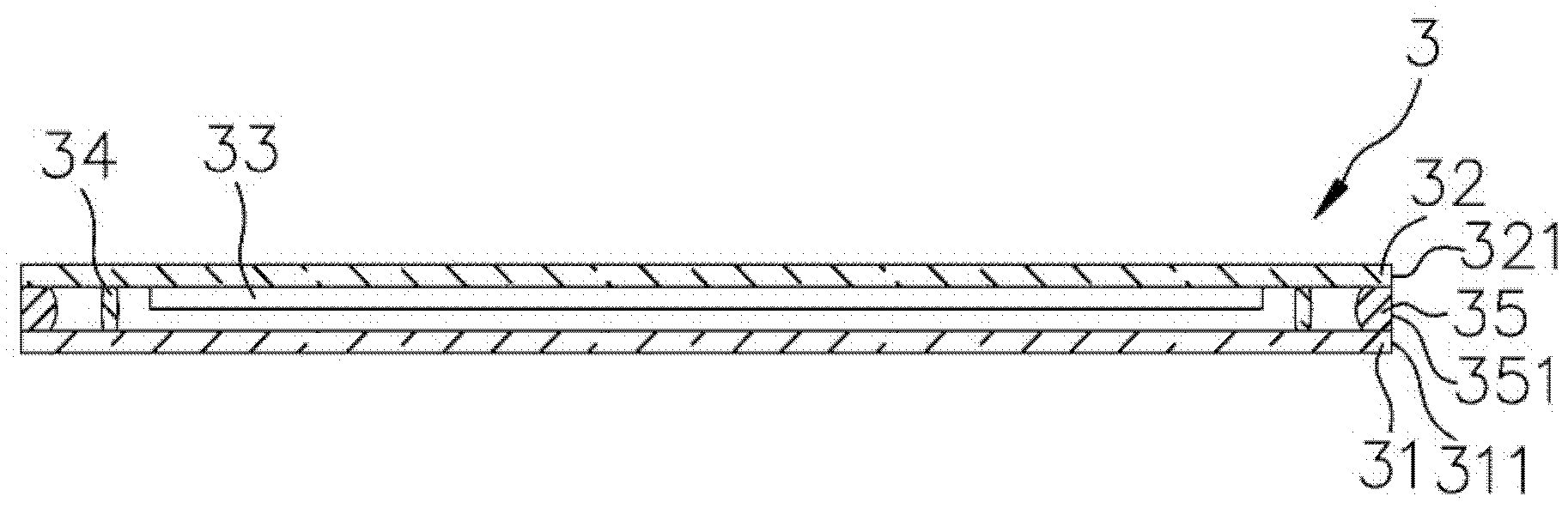

[0048] refer to figure 1 , indicating that an array structure 2, commonly known as a mother board, includes several consecutively arranged packaging structures 3, commonly known as daughter boards. A preferred embodiment includes one of the aforementioned packaging structures 3 , a driving circuit, and a frame for accommodating the packaging structure 3 and the driving circuit.

[0049]The array structure 2 also includes a first mother substrate 21 including several first substrates 31 arranged continuously, and a second mother substrate stacked on the first mother substrate 21 and including second substrates 32 arranged continuously. 22. Several organic light-emitting units 33 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com