Water cooling structure for insert type motor controller

A motor controller, water-cooled heat dissipation technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of poor heat dissipation effect, insufficient heat dissipation area, etc., to avoid insulation problems and device damage problems, large heat dissipation area, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In this embodiment, the water-cooling heat dissipation structure of the plug-in motor control box is set as follows:

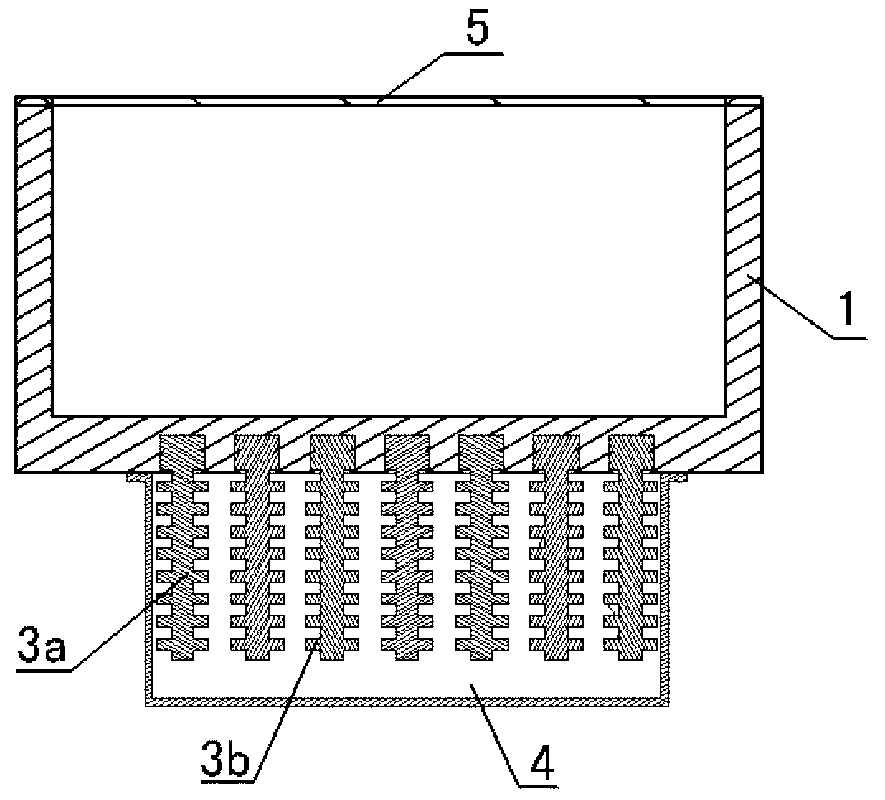

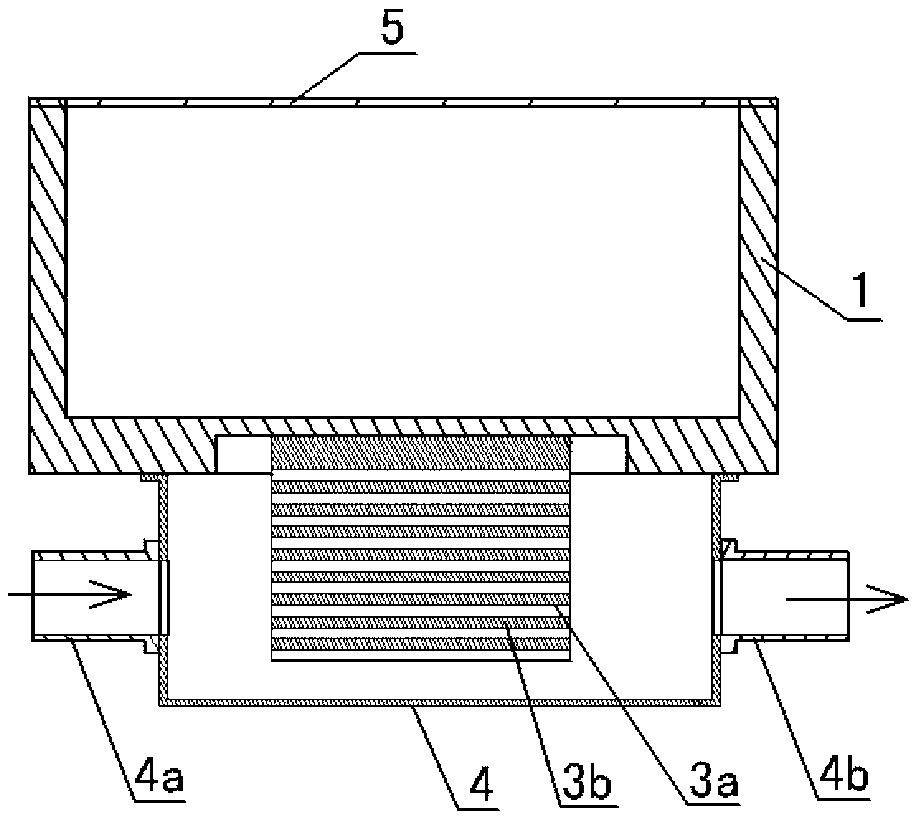

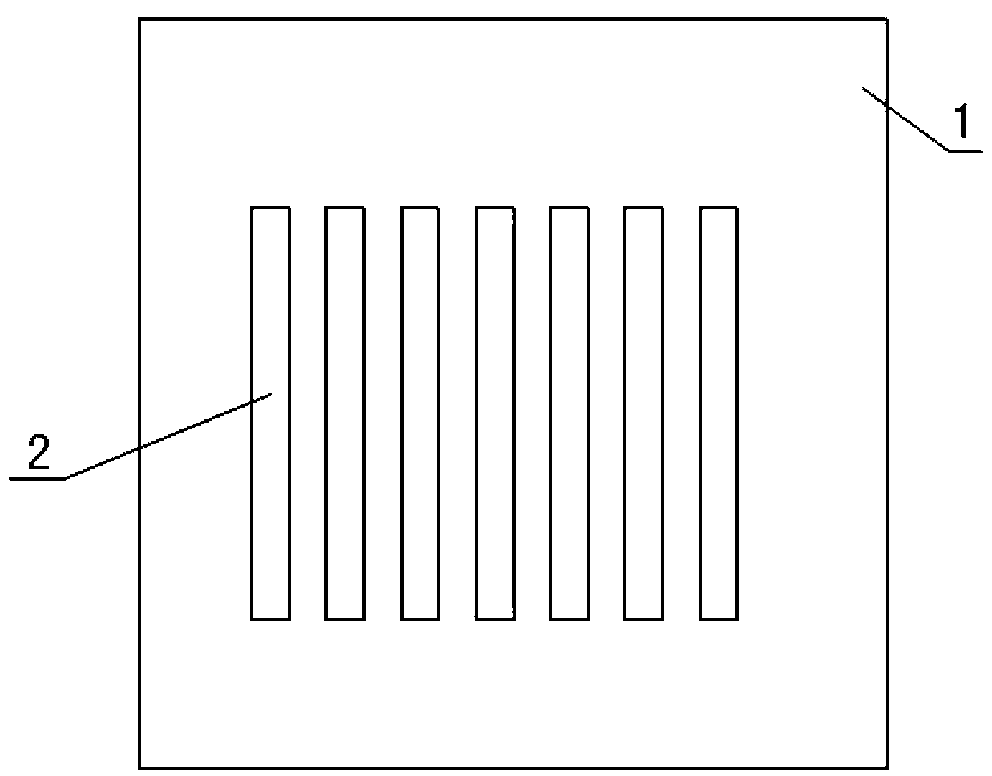

[0019] see figure 1 , figure 2 and image 3 A control box body 1 made of die-casting aluminum and formed by a die-casting process is provided; various bottom grooves 2 are arranged in parallel and at intervals on the bottom of the control box body 1 .

[0020] see Figure 4 In this embodiment, heat sinks are provided separately from the control box body 1, and heat sinks are respectively provided with heat sink fins 3b on both sides of the heat sink substrate 3a. In the groove 2 at the bottom of the control box body 1, it can be fixed in a tight fit or welded; the cooling fins 3b are in the Figure 4 Shown in is horizontal, it can also be vertical or other shapes that are convenient for water diversion.

[0021] like figure 1 , figure 2 As shown, in this embodiment, a water channel 4 is provided at the bottom of the control box body 1 , the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com