Phosphor-coated light-emitting device

A technology for light-emitting devices and phosphors, applied in the directions of light-emitting materials, lighting devices, electroluminescent light sources, etc., can solve the problems of accelerated temperature degradation and insufficient cooling of the phosphor part, and achieve simple structure, high brightness, small size, etc. The effect of etendue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

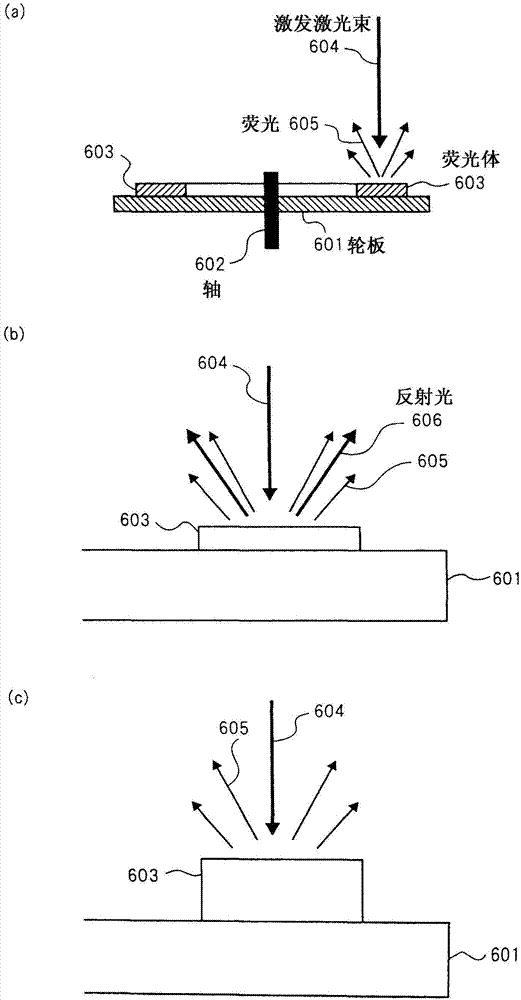

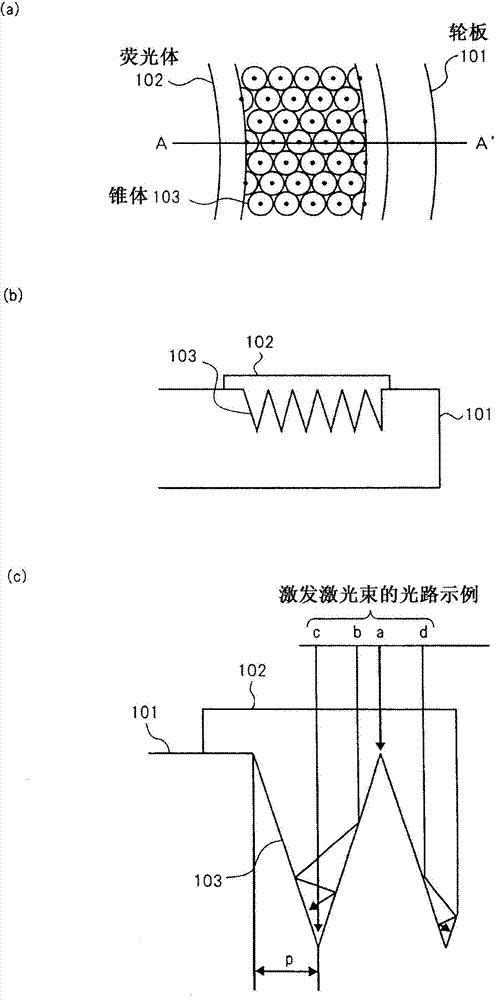

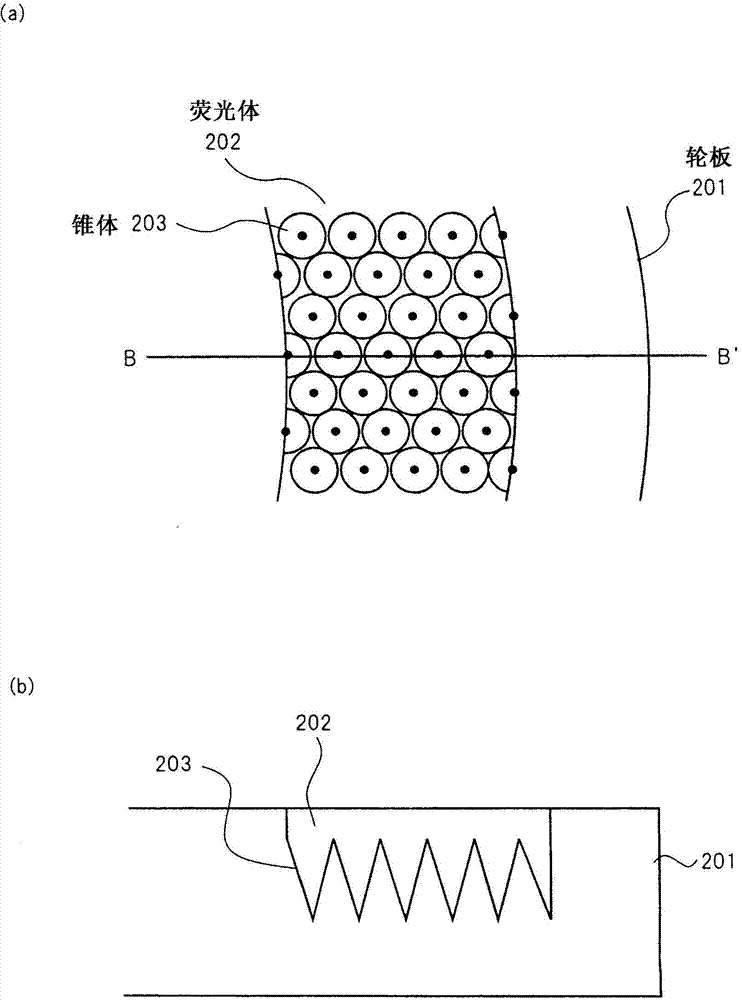

[0037] figure 2 A to 2C are main component views of the phosphor-coated light emitting device according to the first embodiment of the present invention. figure 2 A is a partial plan; figure 2 B is along figure 2 A cross-sectional view taken along line A-A' in A; and figure 2 C is figure 2 Partial enlarged view of B.

[0038] In this example, as in figure 1 In the case of the light-emitting devices shown in A to 1C, the phosphor 102 is formed in a circle shape on a circular flat wheel plate 101 that rotates around an axis. In the position of the wheel plate 101 where the phosphor 102 is formed, a plurality of conical protrusions 103 are formed with the upper surface side of the wheel plate 101 as the apex, and the phosphor 102 enters between the cones 103 .

[0039] The excitation laser beam enters the phosphor 102 from the upper part of the phosphor 102 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com