Cab fixing structure of self-dumping truck for mines

A mining dump truck and fixed structure technology, applied in the superstructure, superstructure, vehicle parts and other directions of trucks, can solve the problem of unfavorable drivers' physical and mental health. Early damage and other problems, to protect physical and mental health, reduce vibration, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

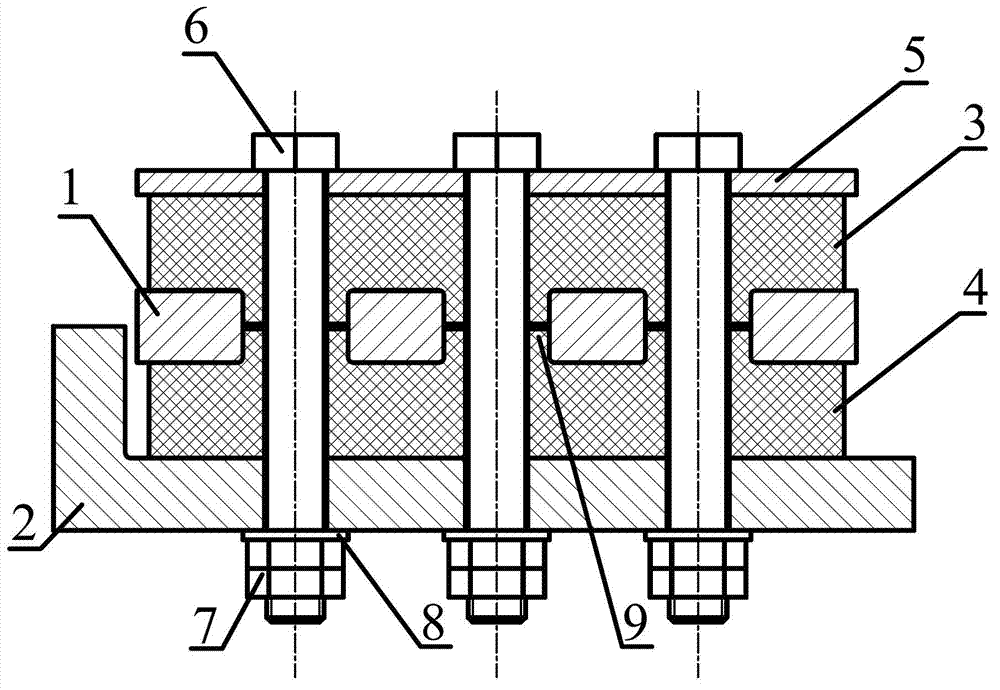

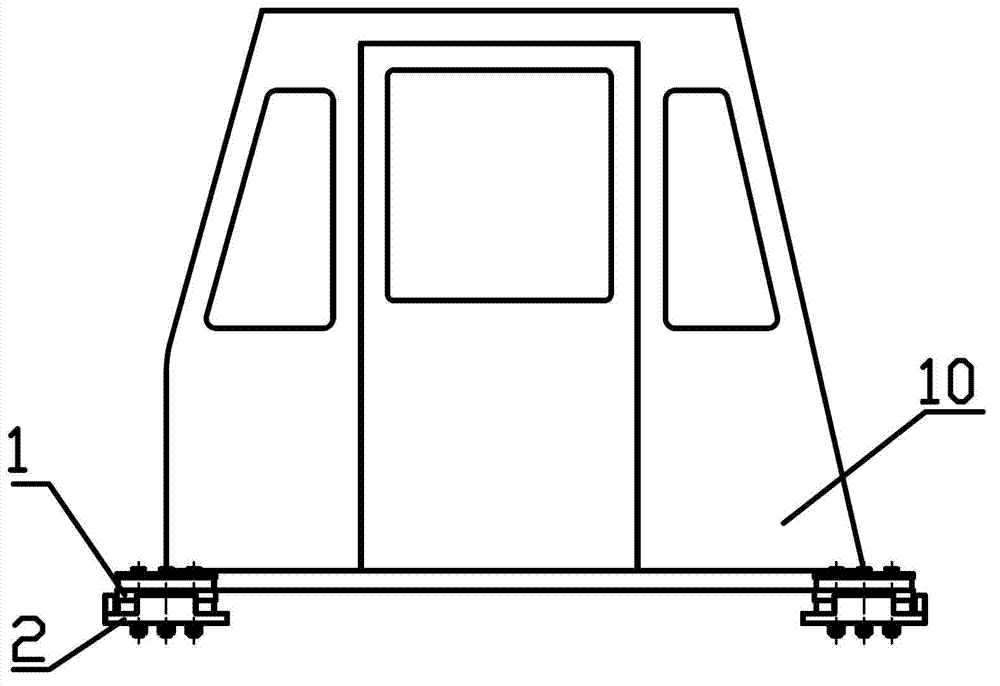

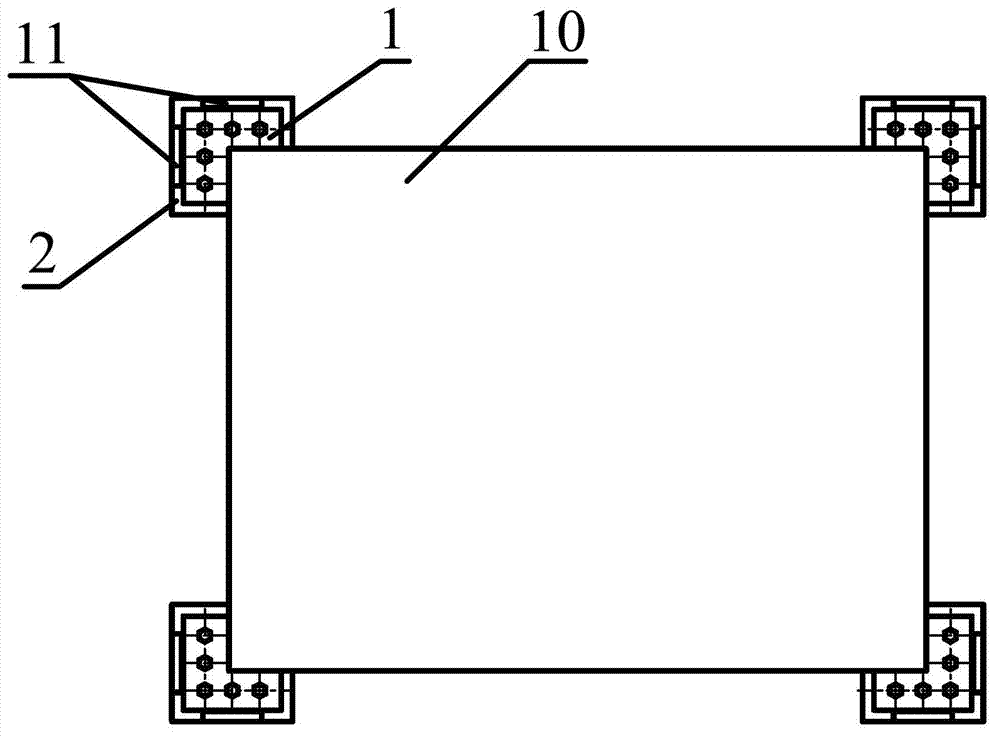

[0022] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-4 As shown, the present invention is mainly applied to mine dump trucks, especially heavy-duty mine dump trucks for large mines. During the operation of the mining dump truck, the vibration from the engine and the road surface is very large; under acceleration, turning and other working conditions, the fixing bolts are subjected to a large shear force. As a preferred embodiment, a cab fixing structure of a mining dump truck includes a base 1, a fixing bracket 2, an upper rubber support block 3, a lower rubber support block 4, a pressure plate 5, bolts 6, nuts 7 and washers 8 ; The base 1 is welded on the bottom of the cab 10, and is provided with a plurality of square holes 12 arranged in an L shape; the fixed bracket 2 is welded on the vehicle frame, and an L-shaped stop 11 is arranged on it The bottom of the upper rubber support block 3 and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com