Modified sodium lignin sulfonate and application thereof as cement grinding aid

A technology of sodium lignosulfonate and lignin, which is applied to modified sodium lignosulfonate and its application field as a cement grinding aid, can solve the problem of low molecular utilization efficiency, low adsorption coverage, poor grinding aid performance, etc. It can solve the problem of waste residue pollution, reduce environmental pollution, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

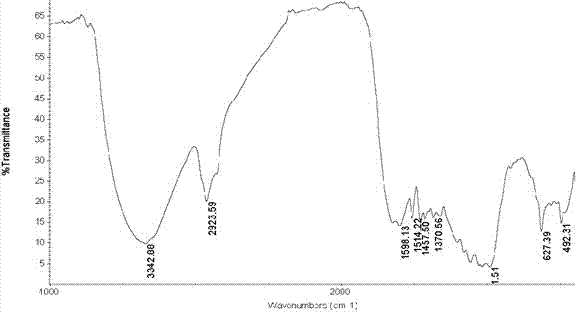

[0018] This example illustrates the structural difference between modified sodium lignosulfonate and traditional sodium lignosulfonate. figure 1 IR spectra of modified lignosulfonate products are illustrated.

[0019] Modified product lignosulfonate at 1598 cm -1 、1514 cm -1 There are typical aromatic ring vibration absorption peaks; at 1457cm -1 Asymmetric C—O bond deformation occurs; at 3342 cm -1 O—H stretching absorption peaks appeared, and these typical absorption peaks indicated that the modified product still had the structure of lignin. It can also be seen from Figure 10 that the modified product is at 1370 cm -1 The syringyl absorption peak appeared, indicating that the syringyl content increased after modification. 1042 cm -1 is the stretching vibration peak of sulfonic acid group, 531 cm -1 The place is the characteristic peak of lignosulfonate in the infrared spectrum fingerprint area, and lignosulfonate has an absorption peak here, indicating that after the...

Embodiment 2

[0021] This example illustrates the specific synthesis method and modification method of sodium lignosulfonate. The method uses corn stalks steamed and exploded and then enzymatically hydrolyzed and fermented to produce cellulose ethanol waste residue as a raw material, and is prepared through the following reaction steps:

[0022] (1) Collect 100 parts of cellulose ethanol waste residue and add water to mix, control the solid content to 30%, add 10% sodium hydroxide solution, stir at 60 for 0.2h, and filter to obtain the filtrate;

[0023] (2) Add 1 part of anhydrous sodium sulfate and 0.1 part of ferric chloride to the filtrate, adjust the reaction pH to 10 with sodium hydroxide solution, and react at 80°C for 4 hours to obtain reaction solution 1;

[0024] (3) Cool the reaction solution 1 to 25°C, control the pH to 10, add 5 parts of formaldehyde solution to the reaction solution at a constant speed, react for 1 hour, and cool to room temperature to obtain the product stock...

Embodiment 3

[0026] This example illustrates another synthesis method and modification method of sodium lignosulfonate. One of the contents of the present invention is to provide a method for producing modified sodium lignosulfonate. The method uses corn stalks to be steamed and exploded and then enzymatically hydrolyzed and fermented to produce cellulose ethanol waste residue as a raw material, and is prepared through the following reaction steps:

[0027] (1) Collect 100 parts of cellulose ethanol waste residue and add water to mix, control the solid content to 75%, add 20% sodium hydroxide solution, stir at 90°C for 1 hour, and filter to obtain the filtrate;

[0028] (2) Add 10 parts of anhydrous sodium sulfate and 1 part of ferric chloride to the filtrate, adjust the reaction pH to 11, react at 90°C for 5 hours, and obtain reaction solution 1;

[0029] (3) Cool the reaction solution 1 to 45°C, control the pH to 11, add 10 parts of formaldehyde solution to the reaction solution at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com