Method for recovering indium from indium-contained sulfuric acid solution and copper ash

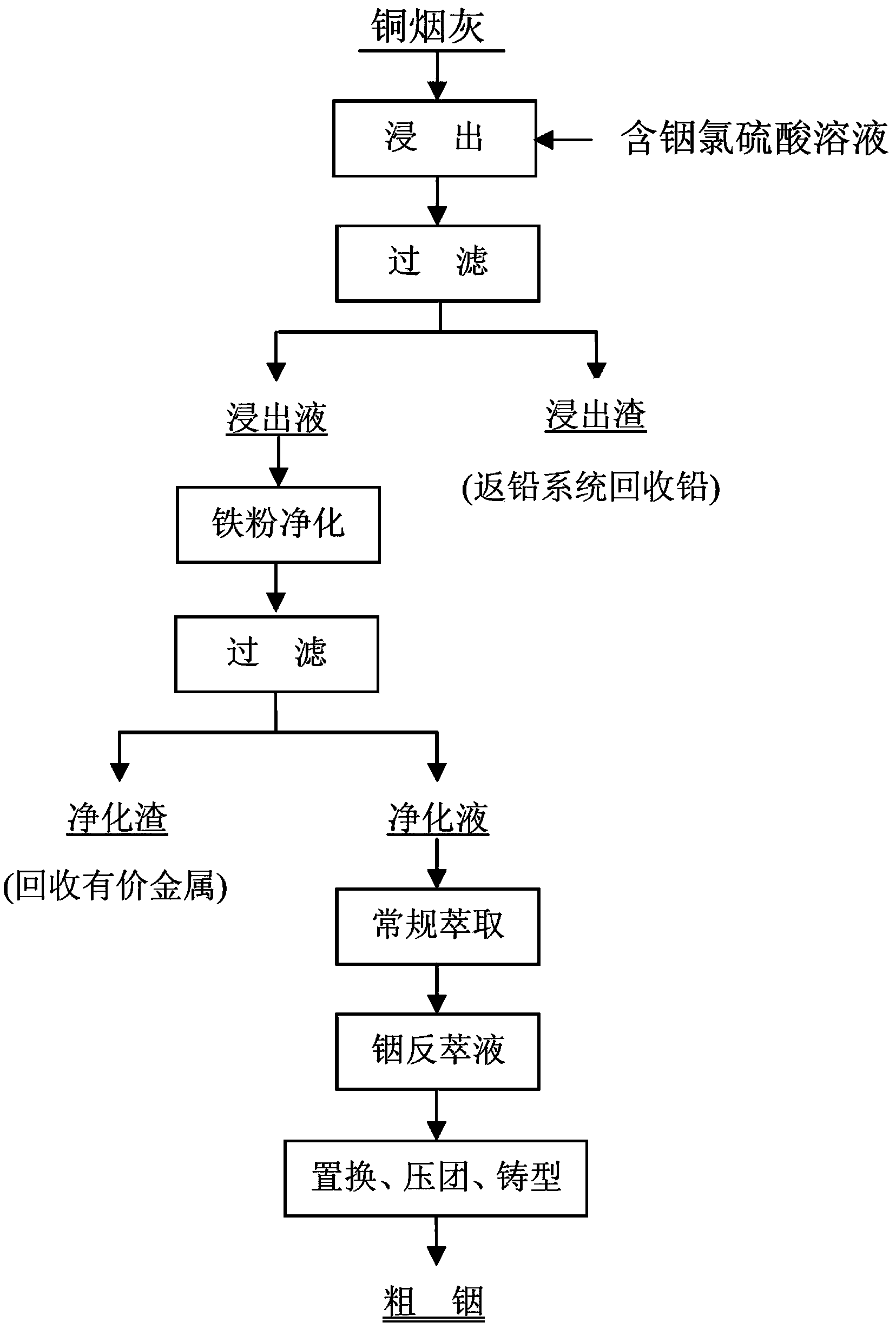

A technology of indium chlorosulfuric acid and copper soot, applied in the field of indium recovery, can solve the problems of low leaching rate, low indium recovery rate, and dispersion of valuable metal copper, so as to improve extraction recovery rate, increase indium leaching rate, and speed up the reaction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The copper soot used in this embodiment includes the following components, by weight percentage: In 0.15%, Cu 1.56%, Bi 0.21%, Sn 1.00%, Pb 37.00%, As3.00%, Sb 0.15%, F 1.50%, Cl 0.40%; Indium-containing chlorosulfuric acid solution A1 includes the following components, and the volume concentration is: In 3+ 7.79g / L, Bi 3+ 0.47g / L, Sn 2+ 0.26g / L, Cl - 15.00g / L, H 2 SO 4 240.00g / L.

[0045] Follow the steps below:

[0046] Step A: Add the copper soot to the leaching tank containing indium-containing chlorosulfuric acid solution A1, the liquid-to-solid ratio (weight percentage) of A1 to copper soot is 3:1, the leaching temperature is 95°C, and the leaching time is 2h; Add water to the leaching tank until the liquid-to-solid ratio (weight percentage) of the leaching liquid to the copper soot is 8:1, and then leaching for 1.5h, with 50g / L sulfuric acid, and solid-liquid separation to obtain the leaching residue and the leaching solution; the leaching residue is returned to ...

Embodiment 2

[0051] The copper soot used in this embodiment includes the following components in weight percentage: In 0.29%, Cu 2.50%, Bi 0.50%, Sn 2.00%, Pb 26.39%, As 5.22%, Sb 0.07%, F 1.50%, Cl 0.87%; Indium-containing chlorosulfuric acid solution A2 includes the following components, and the volume concentration is: In 3+ 6.85g / L, Bi 3+ 0.51g / L, Sn 2+ 0.37g / L, Cl - 60.00g / L, H 2 SO 4 200.00g / L.

[0052] Follow the steps below:

[0053] Step A: Add the copper soot to the leaching tank containing the indium-containing chlorosulfuric acid solution A2 for leaching. The liquid-to-solid ratio (weight percentage) of A2 to copper soot is 4:1, the leaching temperature is 85°C, and the leaching time is 3h; Add water to the leaching tank until the liquid-to-solid ratio (weight percentage) of the leaching liquid to the copper soot is 10:1, then leaching for 1.0h, 35g / L sulfuric acid, solid-liquid separation to obtain the leaching residue and the leaching solution; the leaching residue is returne...

Embodiment 3

[0058] The copper soot used in this embodiment includes the following components, by weight percentage: In 0.60%, Cu 0.80%, Bi 0.10%, Sn 0.60%, Pb 12.00%, As10.00%, Sb 0.30%, F 5.20%, Cl 1.80%; Indium-containing chlorosulfuric acid solution A3 includes the following components, and the volume concentration is: In 3+ 5.46g / L, Bi 3+ 0.54g / L, Sn 2+ 0.38g / L, Cl - 100.00g / L, H 2 SO 4 180.00g / L.

[0059] Follow the steps below:

[0060] Step A: Add the copper soot to the leaching tank containing the indium-containing chlorosulfuric acid solution A3 for leaching. The liquid-to-solid ratio (weight percentage) of A3 to copper soot is 5:1, the leaching temperature is 75°C, and the leaching time is 4h; Add water to the leaching tank until the liquid-to-solid ratio (weight percentage) of the leaching liquid to the copper soot is 12:1, then leaching for 0.5h, 20g / L sulfuric acid, and solid-liquid separation to obtain the leaching residue and the leaching solution; the leaching residue is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com