Cast steel roller and fabrication technology thereof

A technology of cast steel rolls and preparation process, applied in the field of steel rolling rolls, can solve the problems of fine and complicated manufacturing process, high cost pressure, peeling, etc., so as to reduce the fineness and complexity, ensure the rolling performance, and reduce the proportion of elements. The effect of ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

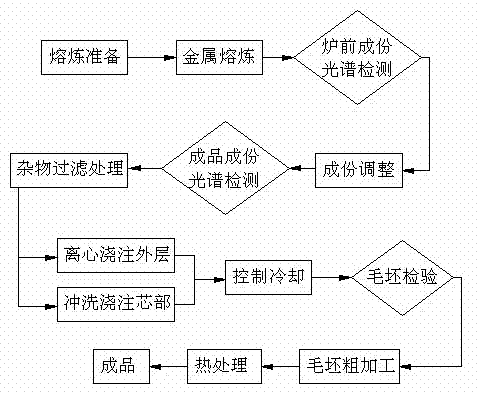

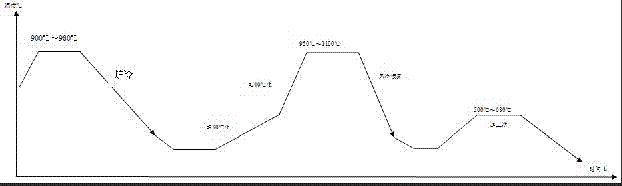

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A cast steel roll, including an alloy outer layer and a core, the chemical composition weight percentage of the alloy outer layer is: C 1.50-2.20%, Si ≤0.060%, Mn 0.40-1.20%, P ≤0.030 %, S ≤0.025%, Cr 3.00-8.00%, Ni 0.00-1.50%, Mo 2.00-8.00%, V 2.00-9.00%, W 0.00-3.00%, Nb 0.00-0.85%, Al 0.00-1.20%, remainder The amount is Fe;

[0018] The weight percent of the chemical composition of the core is: C 2.8-3.4%, Si 1.8-2.6%, Mn 0.3-0.6%, P ≤ 0.08%, S ≤ 0.03%, Mg 0.04-0.06%.

[0019] The key of the present invention is to reduce the proportion of elements that have a large adverse effect in practice, that is, reduce the proportion of Si to: ≤0.060%, reduce the proportion of W to: 0.00-3.00%, reduce the proportion of Nb The ratio of Al is reduced to: 0.00-0.85%, and the ratio of Al is reduced to: 0.00-1.20%, so that the cost of the roll of this embodiment is reduced and the conditions of use are improved. At the same time, the performance is the same or simila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com