Production process for full-elastic silk knitted fabric

A knitted fabric and production process technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of difficult implementation, low yield rate, high production cost, etc., and achieve good product quality, low production cost, and easy The effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A full elastic silk knitted fabric made by the production process of the present invention is obtained through the following production steps:

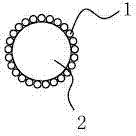

[0028] A. Preparing core-spun yarn: allowing silk 1 to evenly attach to the surface of spandex yarn 2 by reeling to obtain core-spun yarn;

[0029] B. Winding: the core-spun yarn is twisted and wound into a core-spun tube for knitting and weaving;

[0030] C. Knitting and weaving: including weft knitting and warp knitting. Weft knitting is to place each yarn of the core-spun yarn sequentially on each knitting needle of the weft knitting machine along the weft direction to form a weft knitted fabric. The warp knitting is that the yarns are arranged in parallel and wound into a warp beam, and then produced on the machine to obtain a rope-like silk fabric;

[0031] D. Open width: expand the rope-like silk fabric into an open width state;

[0032] E. High temperature setting: place in an environment with a temperature of 180°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com