Method and device for lifting roadbed settlement of existing road

A technology for subgrades and roads, applied in roads, roads, buildings, etc., can solve the problems that restrict the speed, comfort and safety of the road, shorten the service life of the road, increase the investment in road maintenance, etc., to achieve a large lifting height, easy entry into the soil, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

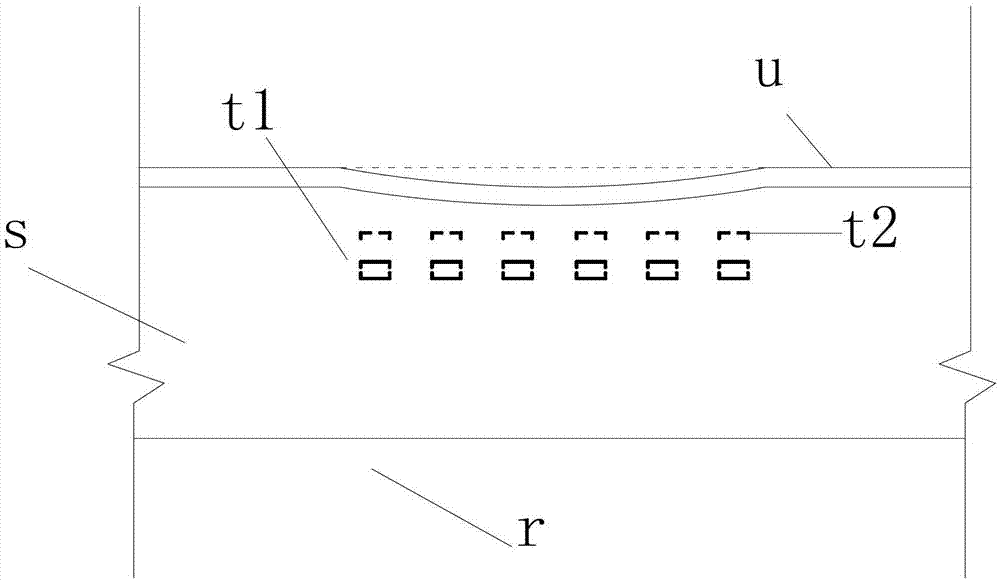

[0060] According to the investigation report of a vehicle jumping treatment project at the bridge head, the subgrade soil layer of the road is cohesive soil, the total thickness of the pavement (u) structure is 60cm, and the height of the subgrade is 5m. Both sides of the road are open, which is convenient for construction. There is a settlement of the entire road surface at the bridge head, the maximum settlement is 31mm, the degree of subsidence is inversely proportional to the distance from the bridge head, and the width of the road surface is 30m

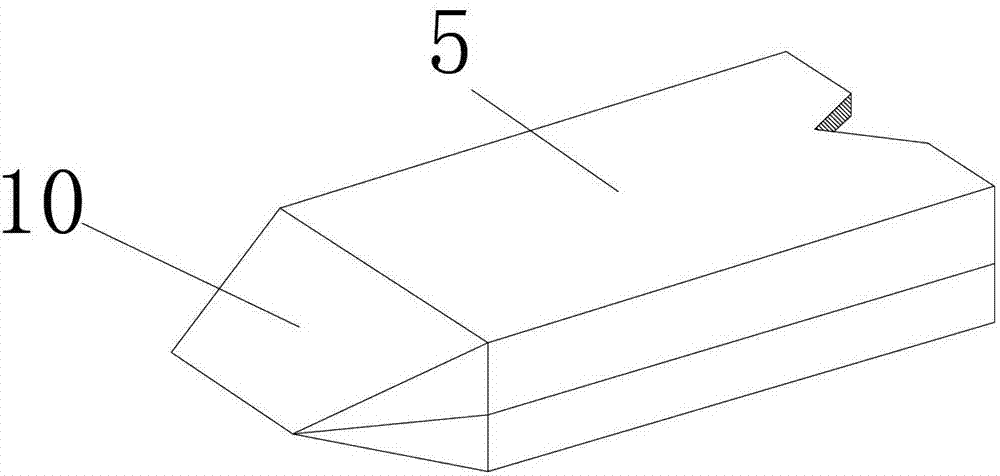

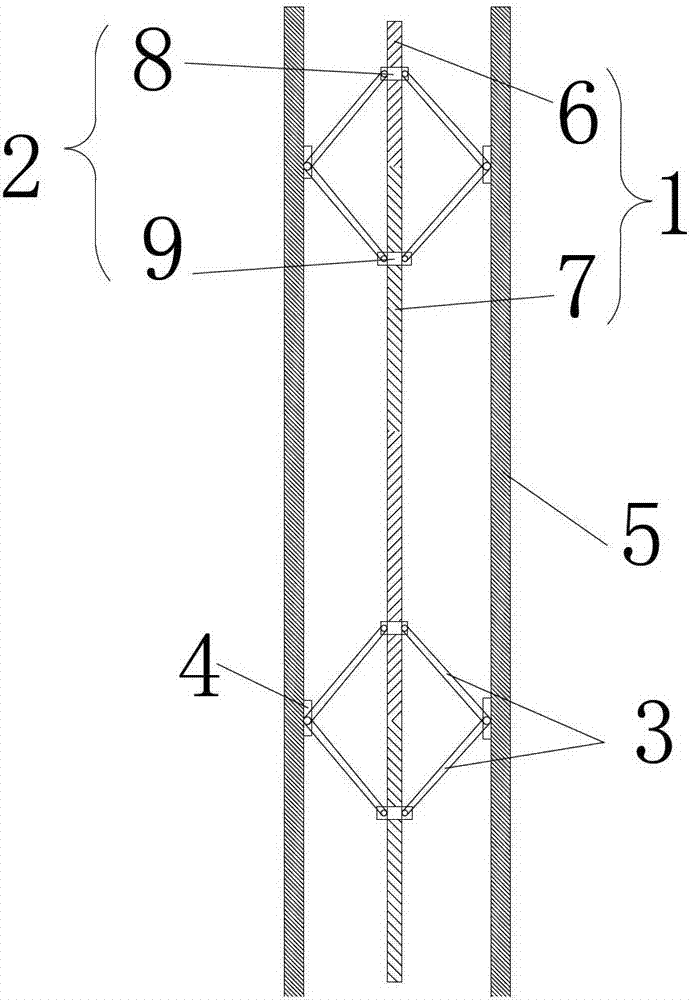

[0061] (1) Adopt the method of simultaneous construction on both sides of the road. In the subsidence section of the road surface at the junction of the road and bridge, a mechanical lifter A1 with an end baffle (10) is horizontally implanted about 50cm below the bottom layer of the road surface structure (such as Figure 3a and Figure 3b ). Use the small drill screw mechanical drilling method to drill holes in the road in the...

specific Embodiment 2

[0066] A road renovation project, according to the survey report: the project site is sandy soil, the total thickness of the road surface structure is 40cm, the height of the roadbed is 4m, the road is built along the riverbed, the construction conditions on both sides of the road are sufficient, the density of the roadbed is not good, the roadbed The maximum settlement is 50mm, and the settlement form of the road surface is half-width road settlement. Road width 20m

[0067] (1) Use the method of half-width construction on the subsidence section of the road. In the subsidence section of the road surface, a single-row hydraulic lifter A2 (such as Figure 4a and Figure 4b ) are welded with end baffles (10). Use the auger earth drilling machine produced by a company in Bazhou City to carry out the soil-discharging method to drill holes in the road on both sides of the road horizontally. The designed hole length is 10m in half width of the road, the width of the hole is 25cm, ...

specific Embodiment 3

[0072] A road comprehensive treatment project, according to the survey report: the project site is sandy clay, the total thickness of the pavement structure is 50cm, the height of the subgrade is 4.5m, the road surface settlement form is uneven partial subsidence, and the settlement area is an irregular area with a diameter of 8m , the maximum settlement of the road surface is 50mm, and the road surface width is 50m.

[0073] (1) In the way of construction on one side of the road in the subsidence area, use the small drill screw mechanical dumping method to drill holes horizontally into the road at 50cm below the bottom of the road surface (u). The hole diameter is 35cm wide and 15cm high; Press the expansion material into the groove (p) of the lifter A3, and at the same time fasten the upper lifting slot plate (m) with the lower lifting slot plate (n). Here, the double-slot expansion lifter A3 (such as Figure 5b ), in the subsidence section of the road surface, the expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com