Bracket for scroll compressor and scroll compressor

A scroll compressor and bracket disk technology, which is applied to machines/engines, rotary piston machines, mechanical equipment, etc., can solve the problems of torsional deformation, large friction loss, and easy damage of the crosshead coupling, and achieve friction loss. Small, low friction and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

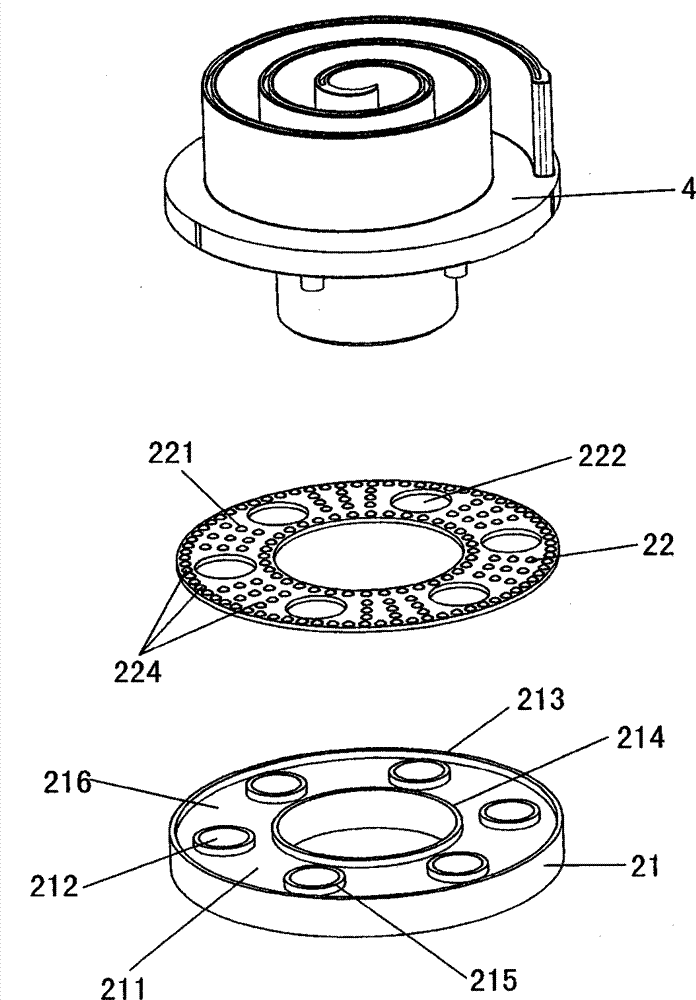

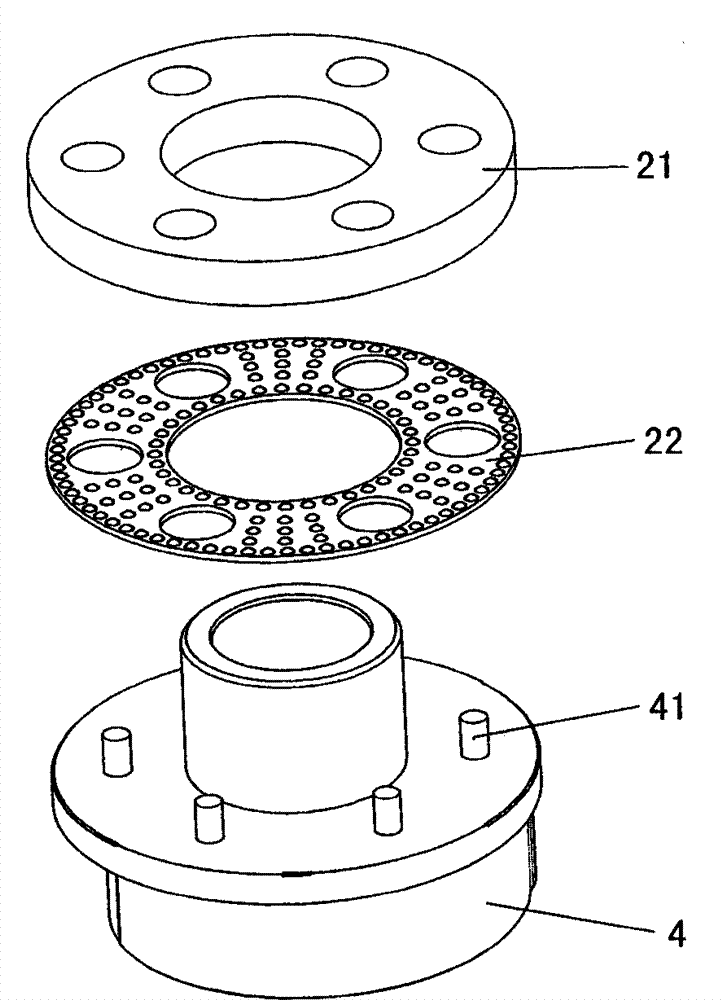

[0029] Through the following examples, combined with the attached figure 1 -7, further specify the technical solution of the present invention. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

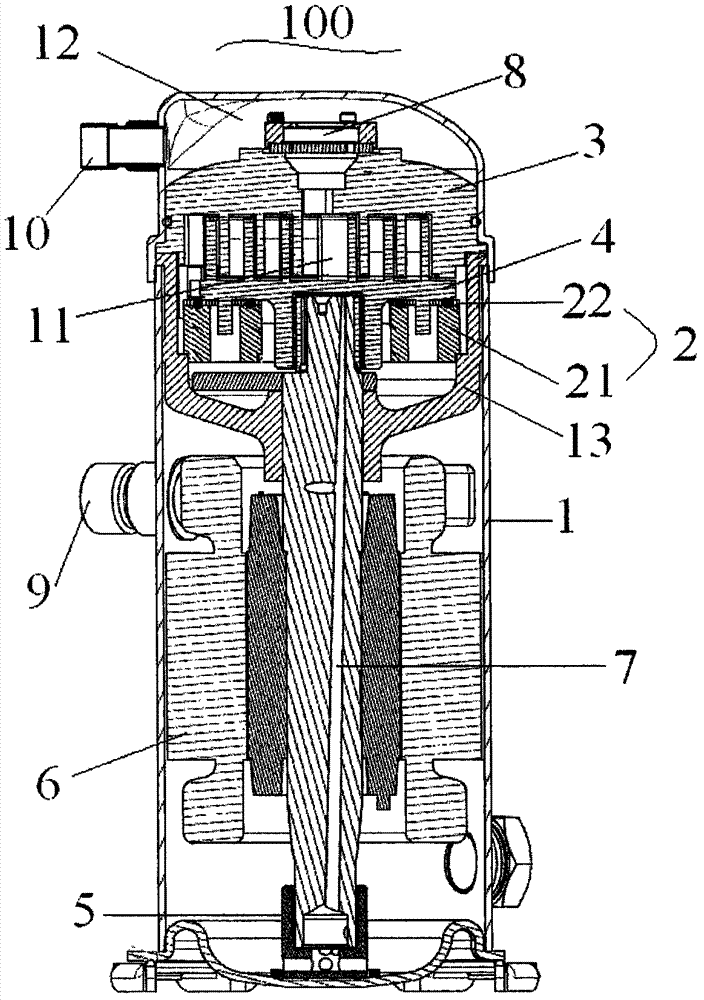

[0030] refer to figure 1 , which shows a cross-sectional view of a scroll compressor 100 according to an embodiment of the present invention. figure 1 The scroll compressor 100 shown includes: a scroll compressor housing 1; a bracket 2, which is fixed in the scroll compressor housing 1; a fixed scroll 3, which is fixed in the scroll compressor housing 1; the movable scroll 4, which is rotatably supported on the bracket 2 and engaged with the fixed scroll 3 to form a gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com