Shifting stable combination valve of power shifting speed changer and shifting and pressure regulating system

A technology for power shifting and transmission, which is applied in the field of smooth shifting combined valve and shifting pressure regulating system, can solve the problems of large size, large shifting impact, complex structure, etc., achieve reasonable oil pressure change characteristics, improve shifting Quality, compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

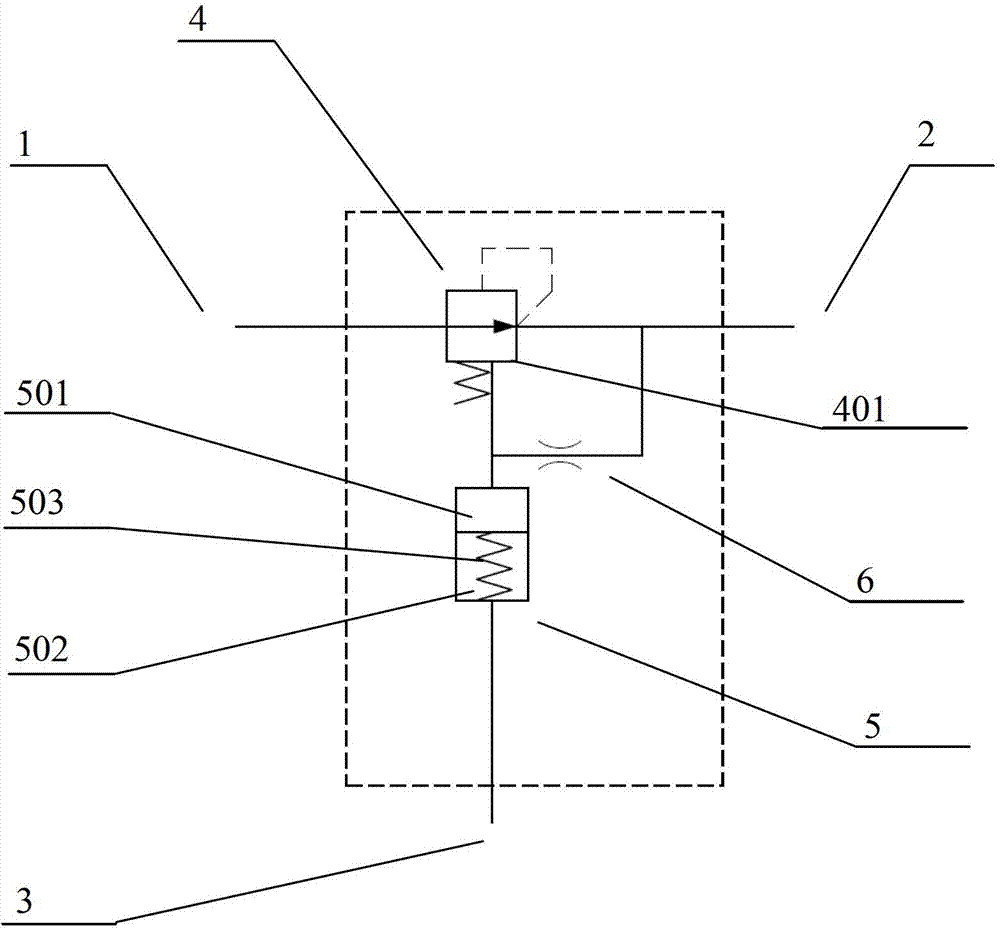

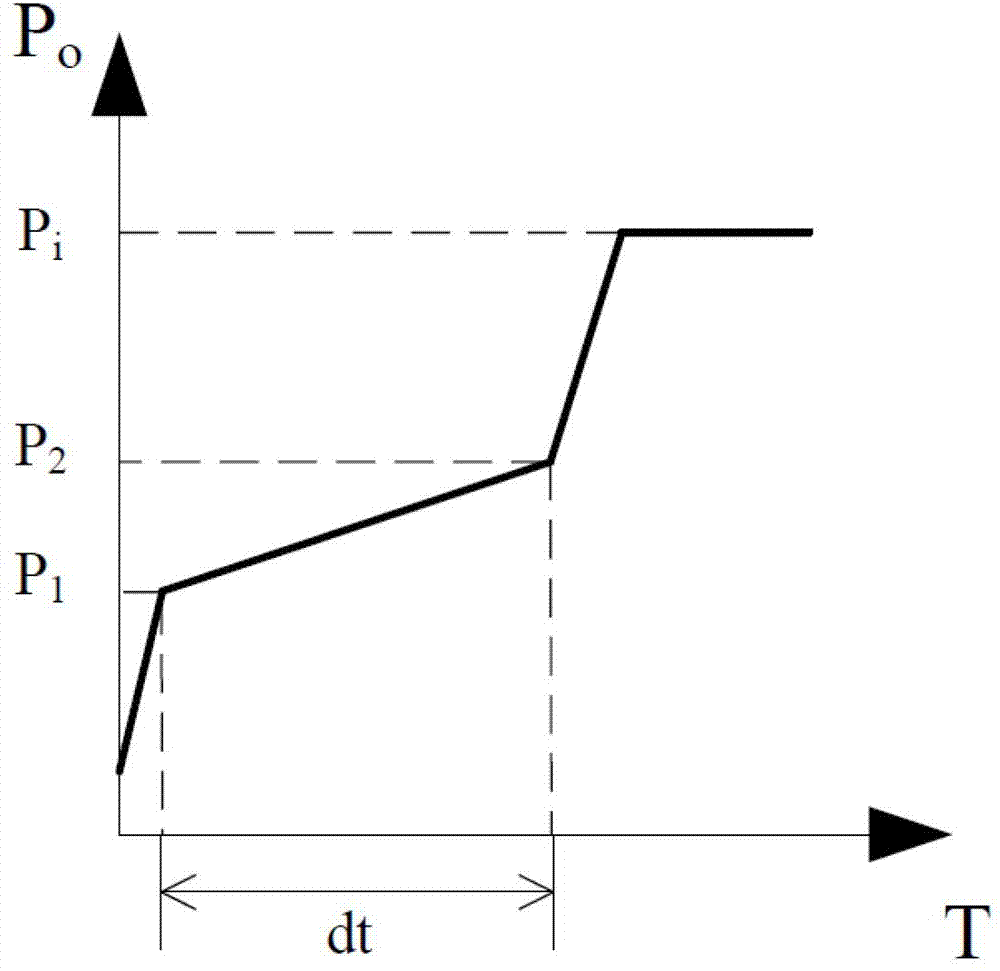

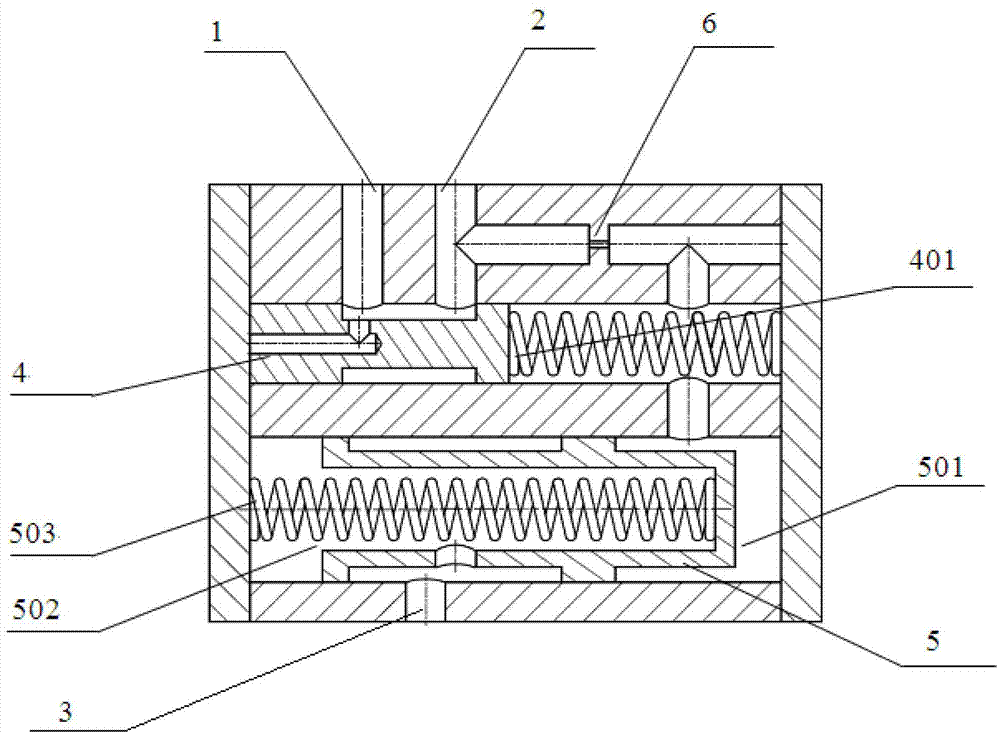

[0020] Such as figure 1 and image 3 As shown, a smooth shift combination valve 20 of a power shift transmission includes an oil inlet 1, an oil outlet 2, a control port 3 for controlling the pressure regulation process, a hydraulic control type pressure reducing valve 4, and an accumulator 5 and orifice 6. The hydraulically controlled pressure reducing valve 4 is connected in series between the oil inlet 1 and the oil outlet 2; the two ends of the orifice 6 are respectively connected with the liquid control port 401 of the pressure reducing valve and the oil outlet 3; the accumulator 5 includes The back cavity 501 and the power cavity 502, the back cavity 501 is connected to the hydraulic control port 401 of the pressure reducing valve, and the power cavity 502 is connected to the control port.

[0021] The oil in the main oil circuit enters through the oil inlet 1 and passes to the hydraulic control pressure reducing valve 4; the accumulator 5 is used as an energy storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com