Multi-vortex combustion method

A combustion method and multi-scroll technology, which can be used in combustion methods, combustion chambers, combustion equipment, etc., and can solve problems such as total pressure loss in a stable working range and restrictions on outlet temperature requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

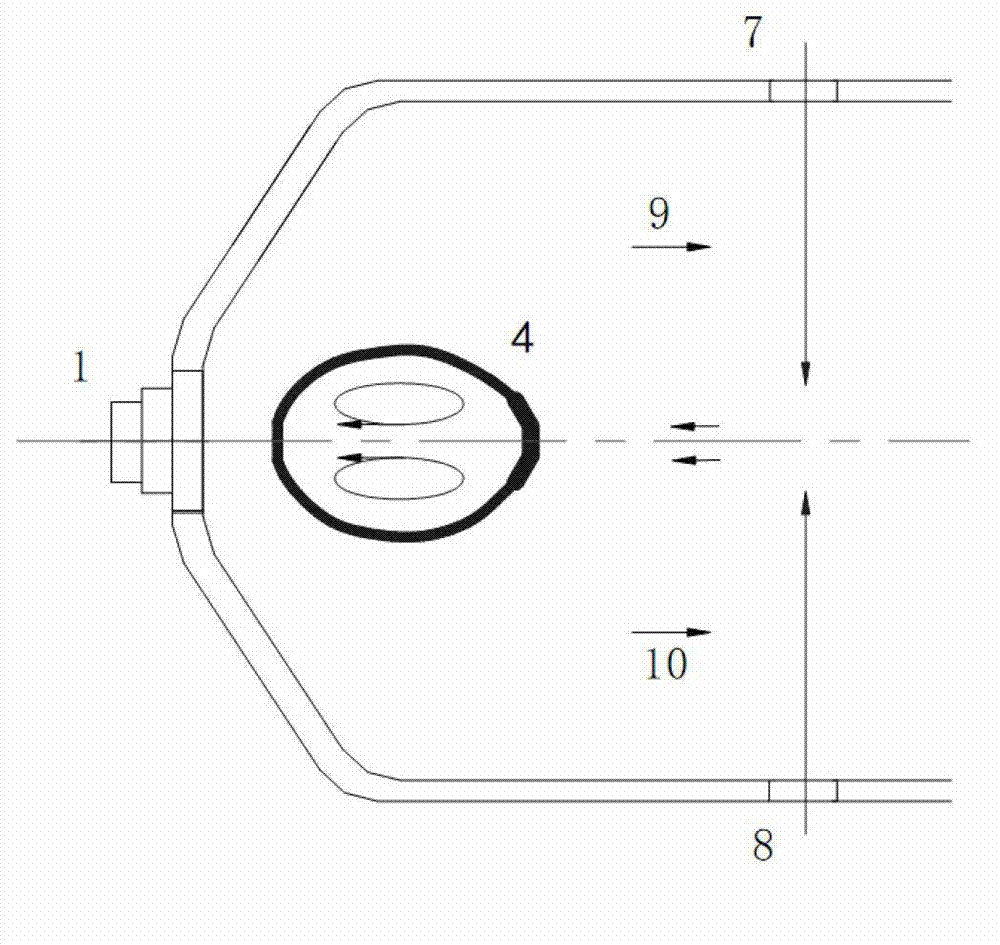

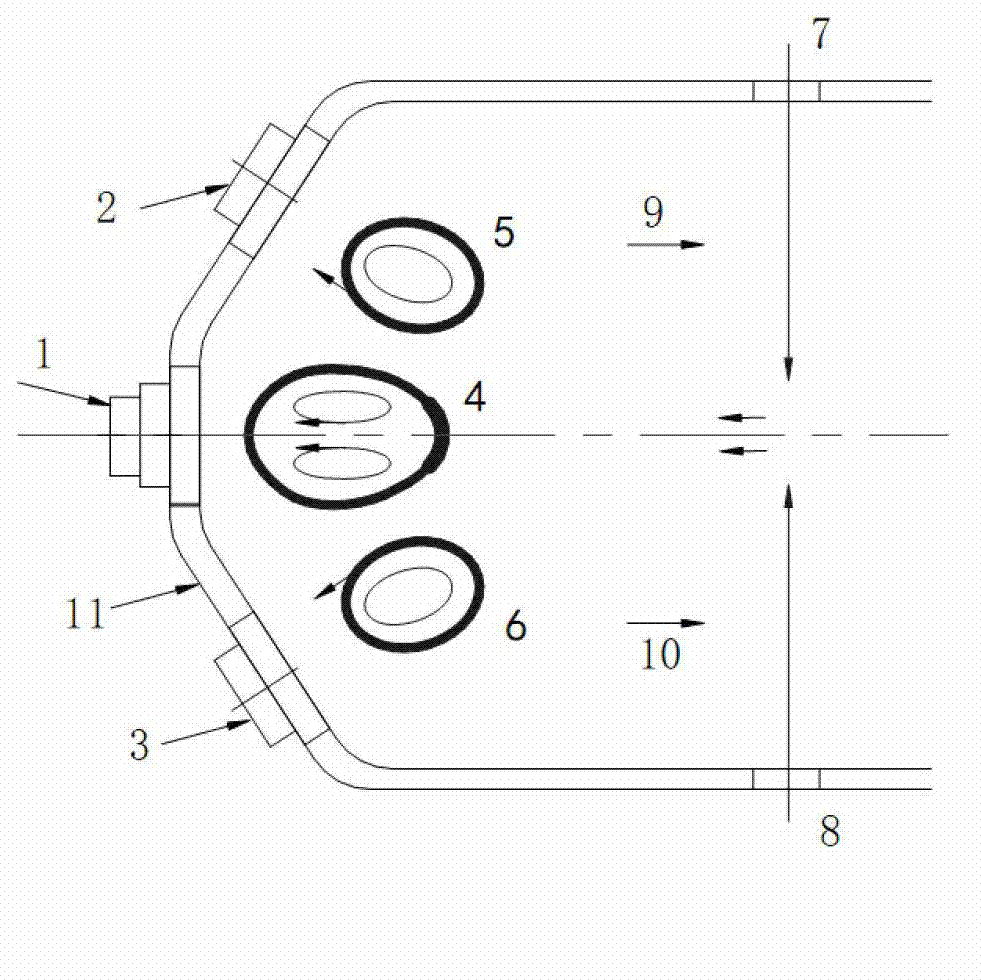

[0052] The combustion-supporting air at the head of the combustion chamber enters from the middle swirl device 1, the upper swirl device 2 and the lower swirl device 3 installed on the head wall 11, as figure 2 shown.

[0053] The middle swirl device 1, the side swirl devices 2 and 3 all use radial swirlers.

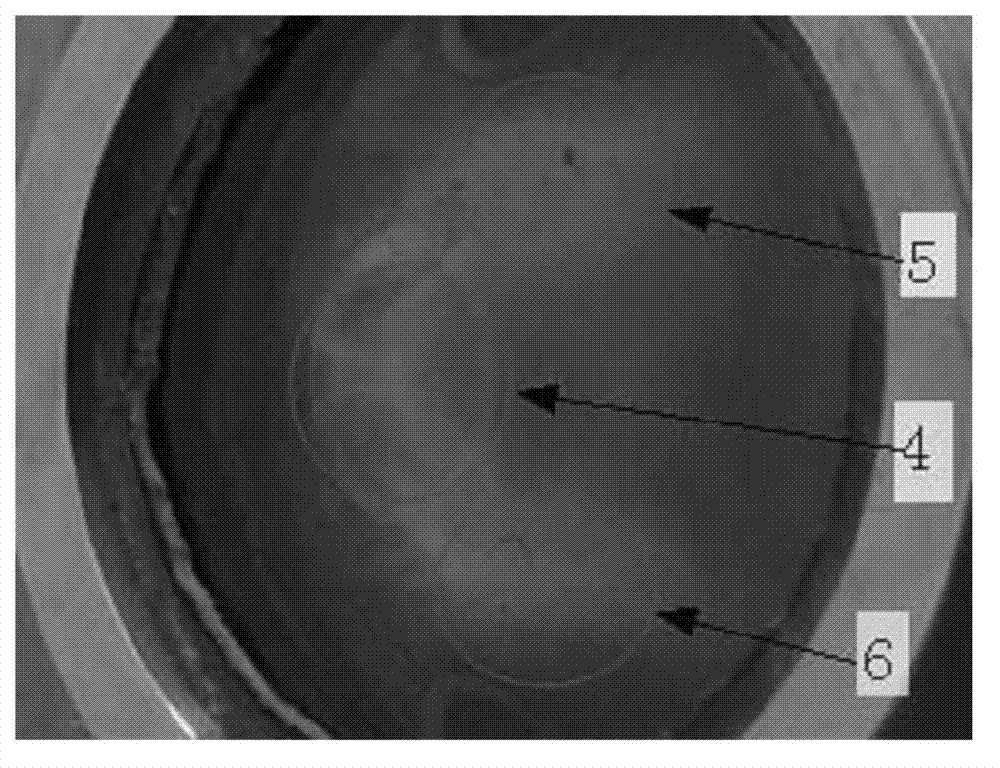

[0054] With the assistance of the upper pair of air injection 7 and the lower pair of air injection 8, multiple closely adjacent recirculation vortex regions are formed near the head of the combustion chamber during the low working condition experiment: as image 3 The middle vortex zone 4, the upper vortex zone 5, and the lower vortex zone 6 are shown.

[0055] When the fuel passes through the channel of the radial swirler of the intermediate swirl device 1, it is mixed with the air that also enters from the channel of the radial swirler of the intermediate swirl device 1 while diffusing to become a semi-premixed combustible gas. Helps reduce pollutant emissions. Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com