Vanadium product melting furnace

A technology for melting furnaces and products, applied in the field of melting furnaces for vanadium products, which can solve problems such as short service life of melting furnaces, easy damage to equipment, loss of vanadium products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

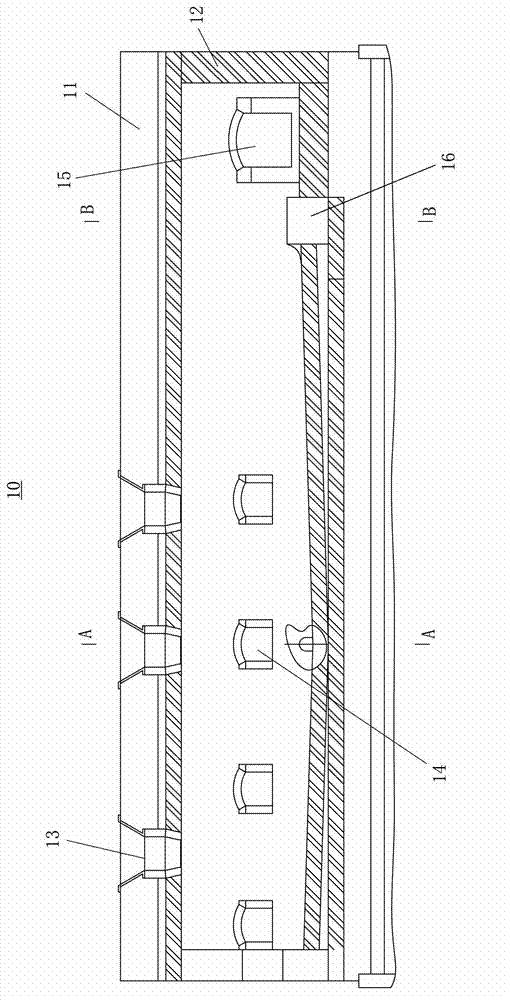

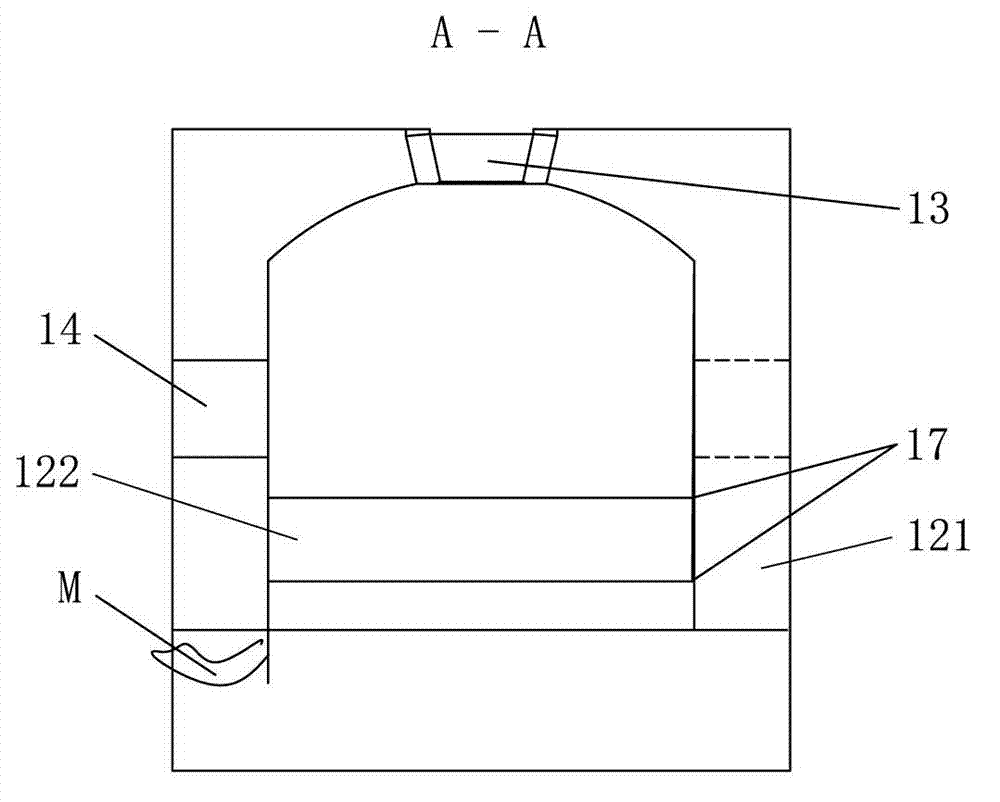

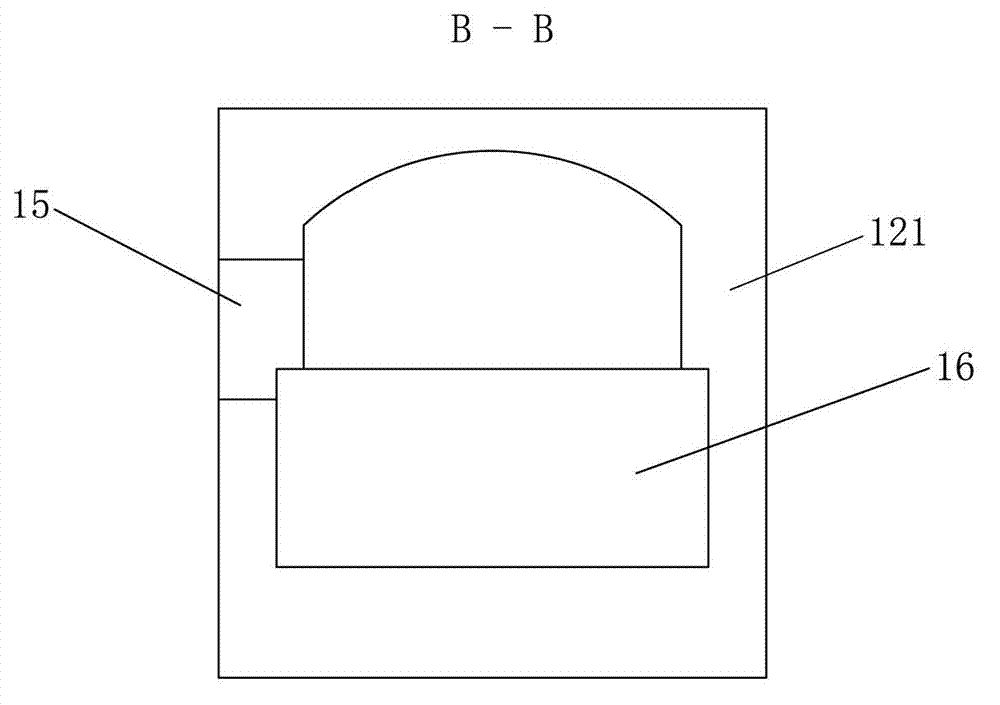

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0028] Different from the melting furnace in the prior art, the melting furnace according to the embodiment of the present invention has been improved in terms of the structure and material of the furnace body, prolonging the service life of the melting furnace under extremely cold and extremely hot working conditions, and prolonging the overhaul interval.

[0029] For example, Panzhihua Iron and Steel Vanadium used to produce V 2 o 5 Vanadium melting furnace, the furnace is at a high temperature of about 600 ℃ for a long time, and the red vanadium powder is melted into a liquid state. The melt has acid corrosion. Under the long-term high temperature, corrosion, and washing of the melt, the furnace wall and furnace bottom lining brick Fracture and deformation are fast, especially causing many gaps in the masonry between the furnace bottom and the furnace and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com