Production method of novel efficient rat poison

A production method and high-efficiency technology, applied in rodenticides, botany equipment and methods, biocides, etc., can solve problems such as improper use of rodenticides, inability to eliminate pests, and drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

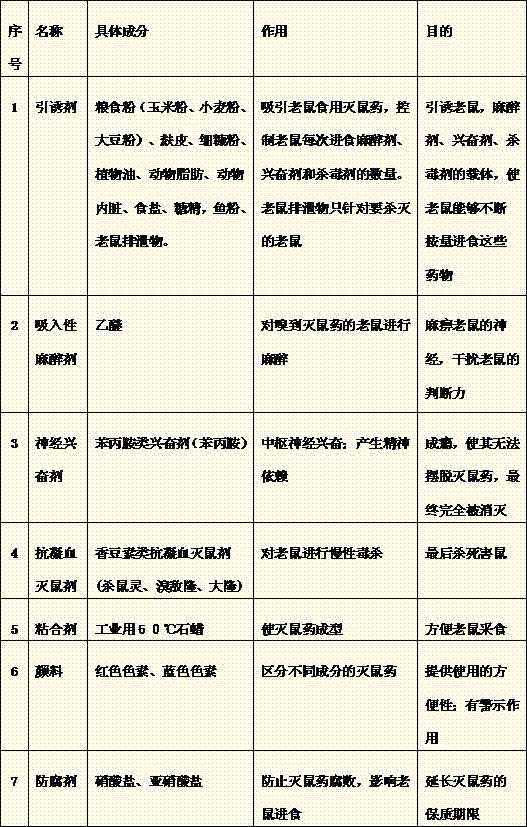

Method used

Image

Examples

Embodiment

[0012] Raw materials are prepared in parts by weight,

[0013] 1) Consists of 5 parts of corn flour, 10 parts of bran, 6 parts of industrial paraffin at 60°C, 1 part of mouse excrement, 1.0 part of ordinary fish meal, 0.5 part of animal offal, 0.5 part of animal fat, 0.1 part of vegetable oil, 0.01 part of table salt, saccharin 0.01 part, 0.005 part of amphetamine, 0.001 part of warfarin, 0.001 part of ether, 0,001 part of nitrate, 0.01 part of red pigment;

[0014] 2) Consists of 50 parts of wheat flour, 40 parts of fine bran powder, 36 parts of industrial paraffin at 60°C, 30 parts of mouse excrement, 10 parts of ordinary fish meal, 10 parts of animal offal, 5 parts of animal fat, 3.0 parts of vegetable oil, and 0.5 parts of table salt , 0.5 parts of saccharin, 0.5 parts of amphetamine, 0.25 parts of bromadiolone, 0.05 parts of ether, 0.1 parts of nitrite, and 0.3 parts of blue pigment;

[0015] 3) Composed of 40 parts of soybean powder, 30 parts of bran, 20 parts of paraff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com