Laboratory organic solid purification device and method based on solid-liquid phase transition principle

An organic solid and solid-liquid phase transition technology, applied in laboratory equipment, chemical instruments and methods, heat treatment, etc., can solve the problems of difficult to exceed 99% purity, high cost, time-consuming and labor-intensive, etc. The effect of convenience and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

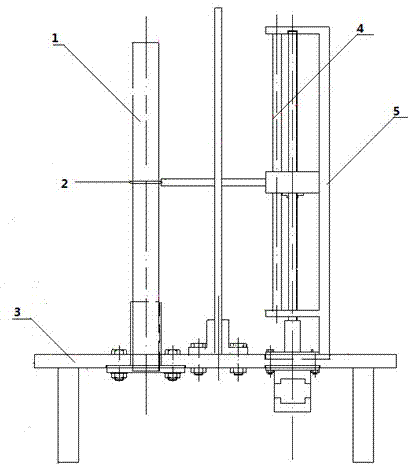

[0020] The regional smelting device used for laboratory organic solid purification of the present invention includes a smelting furnace and a heating part; the top of the smelting furnace is provided with a variable-diameter raw material inlet, and a control heating ring 2 is provided on the side of the smelting furnace in parallel with the smelting furnace The moving track 5 and the heating ring 2 are arranged on the moving track, a windshield 4 is arranged between the heating ring and the moving track, and both the windshield and the heating ring moving track are fixed on the base 3 .

[0021] The melting furnace is made of glass with high silicon dioxide content and can withstand a high temperature of 500 degrees Celsius.

[0022] The entire smelting furnace is designed with a variable diameter on the upper part, which is convenient for dropping organic matter in, and the top can be sealed with a medical rubber stopper, and a nitrogen-filled balloon can be inserted for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com