Retaining ring forming die

A technology for forming molds and forming dies, which is applied in the field of stamping die manufacturing, can solve the problems of reducing the bearing capacity of wheel retaining rings, and the arc-shaped joints of wheel retaining rings are prone to cracking, etc., and achieve the goal of thickening the thickness and improving the bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

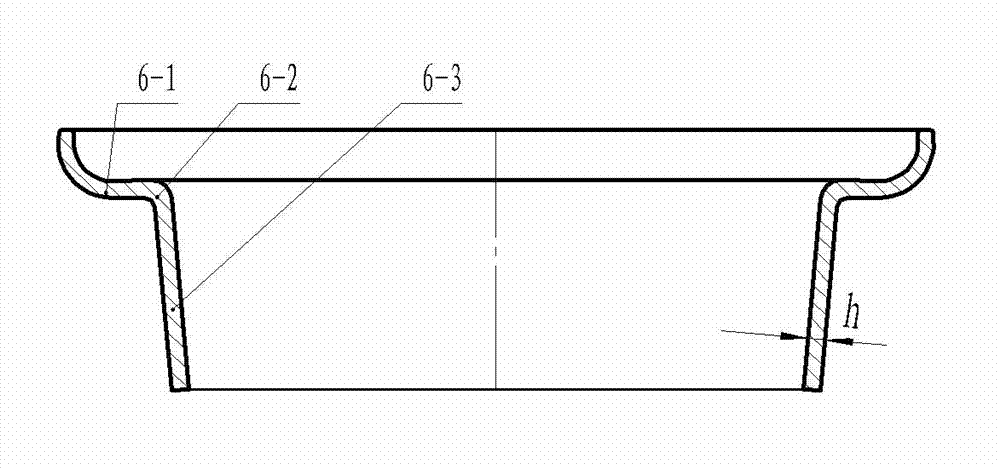

[0016] Such as figure 1 The wheel retaining ring of the heavy-duty engineering vehicle shown is a circular piece that is connected by an arc-shaped rib 6-1 and a seat ring 6-3 through an arc-shaped connecting portion 6-2. The arc-shaped rib 6-1 and the The bending direction of the arc-shaped connecting portion 6-2 is opposite, and the bevel angle of the seat ring 6-3 is a cone with a large top and a small bottom with an angle of 5 degrees to 7 degrees. The thickness of the wheel retaining ring is the thickness h of the blank, h is 16mm.

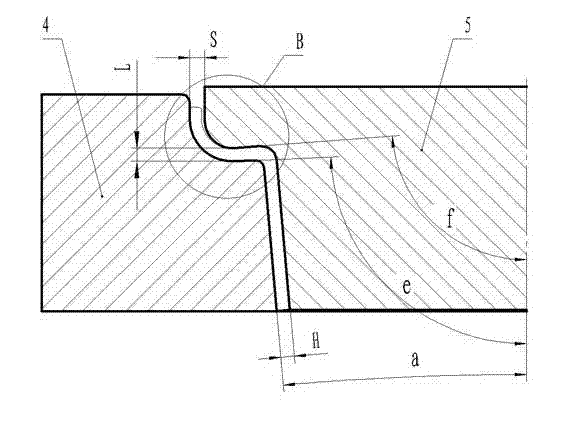

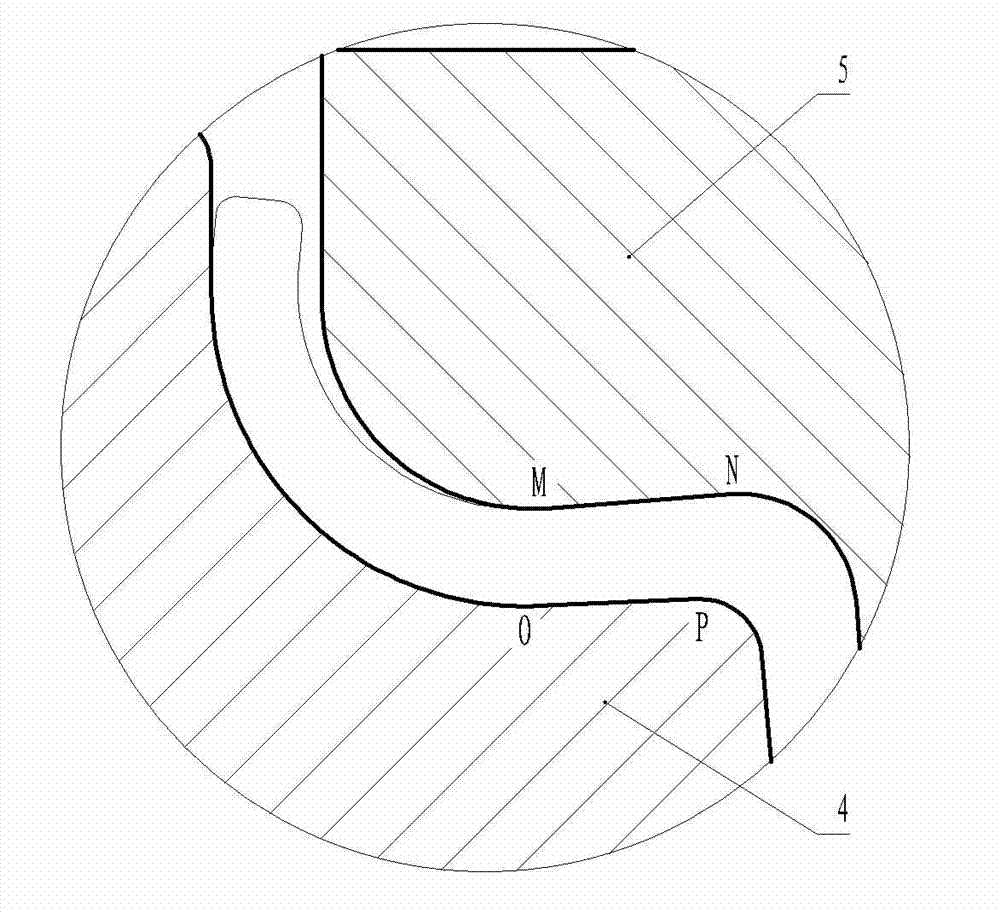

[0017] Such as figure 2 The shown retaining ring forming die includes a forming die 4 and a forming punch 5 with a cavity. The lower section of the forming die 4 cavity is a tapered hole with a large upper part and a smaller lower part with an oblique angle a. The oblique angle a of the tapered hole is The angle of angle is 5 degree; The top of forming die 4 die cavity is provided with the inner cylindrical surface of one section diameter ...

Embodiment 2

[0019] The lower section of the forming die 4 cavity is a tapered hole with a large upper part and a smaller one, and the angle of the oblique angle a of the tapered hole is 7 degrees; the angle of the oblique angle e of the inner conical surface between the two curved surfaces of the forming die 4 is 87 degrees; the angle f of the oblique angle f of the outer conical surface between the two curved surfaces of the forming punch 5 is 85 degrees. Other features are the same as in Example 1.

Embodiment 3

[0021] The lower section of the forming die 4 cavity is a tapered hole with a large upper part and a smaller lower part, and the angle of the oblique angle a of the tapered hole is 7 degrees; The best is 87.6 degrees; the angle f of the oblique angle f of the outer conical surface between the two curved surfaces of the forming punch 5 is the best 85.6 degrees. Other features are the same as in Example 1.

[0022]When working, the blank that has completed the first pressing process is placed in the cavity of the forming die 4 of the retaining ring forming mold, and the forming punch 5 is driven to press the blank from top to bottom. When the forming punch 5 drops to the setting position Time, the gap H between the cone of the lower section of the forming punch 5 and the taper hole of the lower section of the forming die 4 cavity is 16.3 millimeters, exit the forming punch 5 and finish pressing the wheel retaining ring. When the forming punch 5 dropped to the set value, the gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com