Three-roller multi-station adjusting forming equipment for producing radiating tubes

A technology for forming equipment and heat dissipation pipes, applied in heat exchange equipment and other directions, can solve the problems of waste of raw materials, increased production costs of enterprises, working efficiency of forming equipment, and low product yield of product accuracy, so as to save raw materials and improve the yield of finished products. , to achieve the effect of multi-directional adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

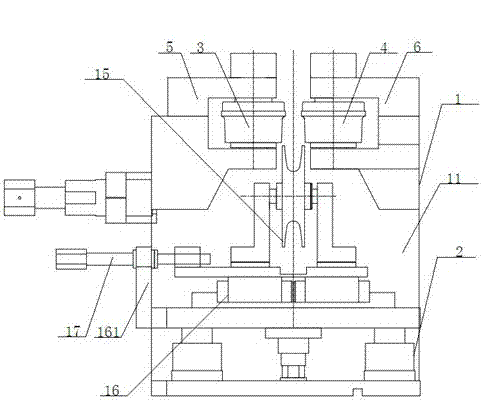

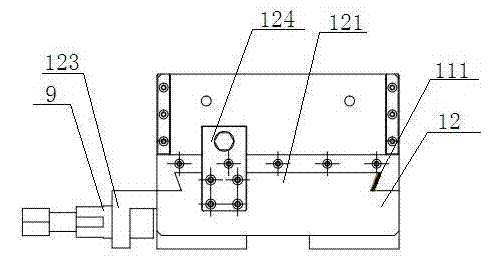

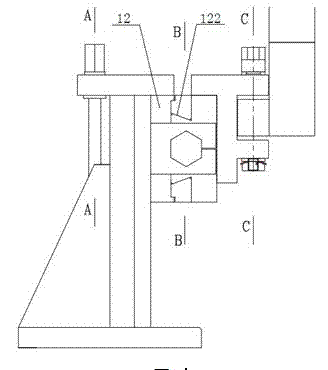

[0018] Such as figure 1 , 2 , 3, 4, 5, and 6, the present invention includes an upper roll forming device 1 and a lower roll forming device 2, and the upper roll forming device 1 includes a frame body 11 and a connecting slider 12, and the frame body 11 is vertically The dovetail groove A111 is provided in the direction, the dovetail guide rail A121 is arranged vertically on one side of the connecting slider 12, and the dovetail groove B122 is arranged horizontally on the opposite side, the dovetail groove A111 of the rack body 11 and the dovetail connecting slider 12 The guide rail A121 is matched and clamped, and the connecting slider 12 is provided with the left forming roller 3 and the right forming roller 4 through the dovetail groove B122. The connecting slider 12 is slidably connected, and the left forming roller 3 and the right forming roller 4 are respectively rotatably connected to the sliding base A5 and the sliding base B6. One end of the horizontal adjustment sc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap