Multifunctional machine tool chuck

A multi-functional machine tool and chuck technology, applied in the direction of chucks, etc., can solve the problems of short service life, reduce enterprise productivity, affect production progress, etc., achieve low manufacturing cost, long service life and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

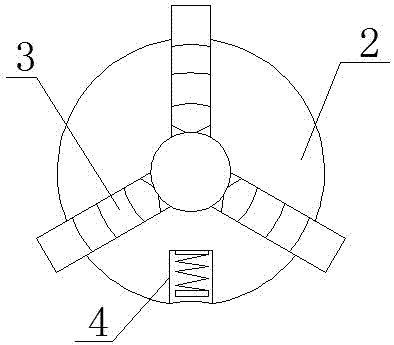

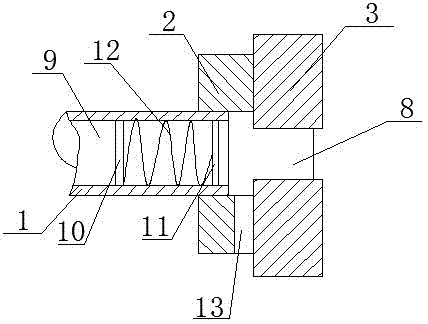

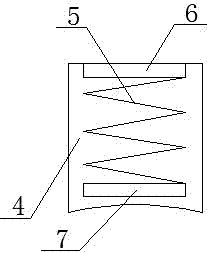

[0015] refer to figure 1 , figure 2 , image 3 and Figure 4 A multifunctional machine tool chuck shown includes a main shaft 1, a chuck body 2, claws 3, a lock hole 4, a first spring 5, a fixed block 6 and a retainer 7, and the middle part of the chuck body 2 is provided with The mounting hole 8 that is connected with the outer diameter of the main shaft 1, the chuck body 2 is installed on the outer diameter of the main shaft 1, the middle part of the main shaft 1 is provided with a through hole 9 for placing the workpiece, and the through hole 9 is far away from the chuck body 2 places are provided with stoppers 10, and the said through hole 9 is provided with a chip stopper 11 near the chuck body 2, and a second spring 12 is arranged between said chip stopper 11 and the stopper 10, and said claw 3 is installed on the chuck body 2, the lock hole 4 is set on the outer surface of the chuck body 2, the first spring 5 is installed in the lock hole 4, and the stop piece 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com