Automatic separable belt type conveying system

A technology of belt conveying and automatic sorting, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high error rate, complexity and low degree of intelligence, to improve the accuracy of work, the overall design is reasonable, and the The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

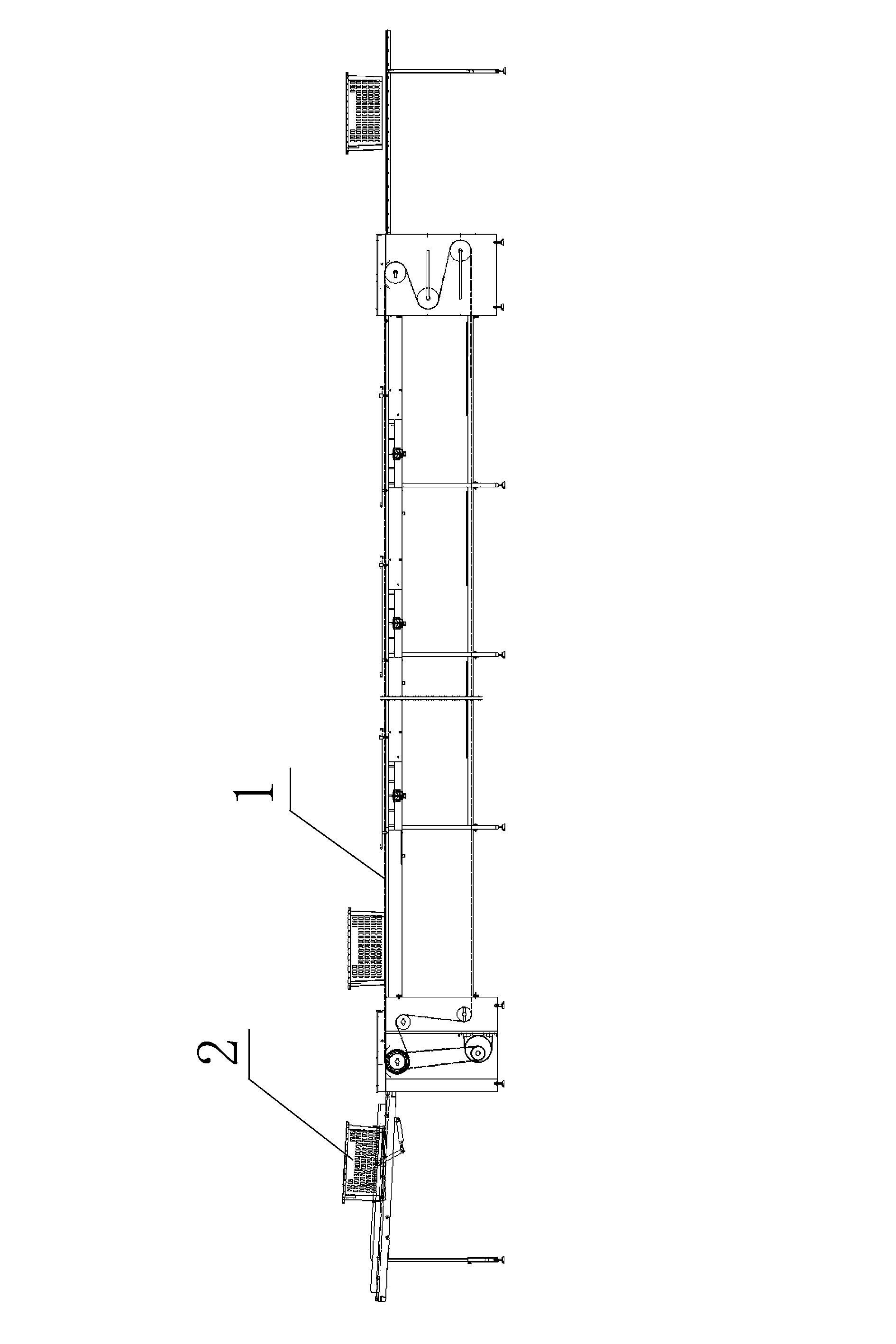

[0008] The present invention will be further described below with reference to the accompanying drawings.

[0009] The present invention is an automatic sorting belt conveyor system, which mainly includes a conveyor belt 1, which is different from the prior art in that: one side of the conveyor belt 1 is provided with 1-999999 outlets, and there is 1 conveyor belt There are 1-999999 interception rods corresponding to the delivery port, a slideway is provided between the conveyor belt 1 and the delivery port, a number of loading baskets 2 are provided at the conveyor belt 1, and intelligent information is provided at the 2 loading baskets Identify the barcode, and the destination (export) information of the goods to be delivered is obtained by scanning the barcode attached to the loading basket.

[0010] During specific implementation, the intercepting rod is driven by a cylinder, the cylinder is connected to a solenoid valve, and the solenoid valve is connected to a main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com