Payoff tension precise balancing device of tungsten wire rope winding machine

A technology of pay-off tension and balance device, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of wire rope load tension reduction, broken wire, loose and rough shape of tungsten wire rope, etc. The tension is uniform, the wire arrangement is neat, and the surface is smooth and beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

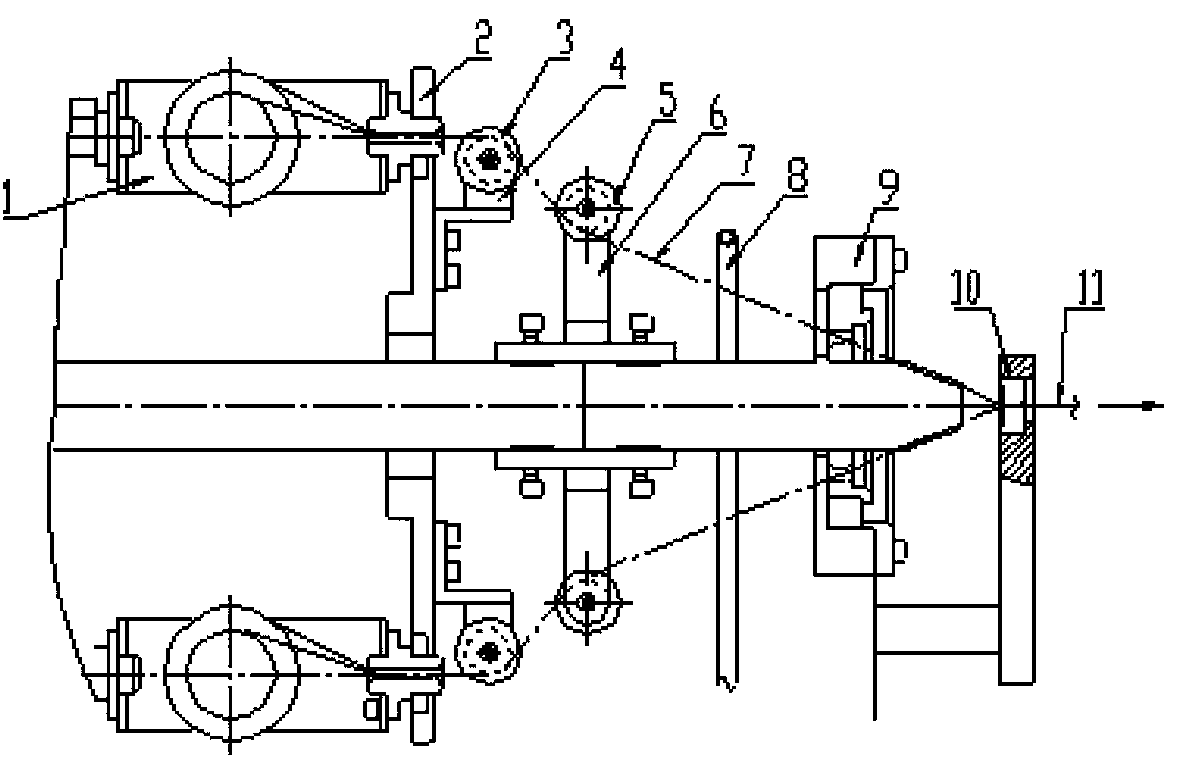

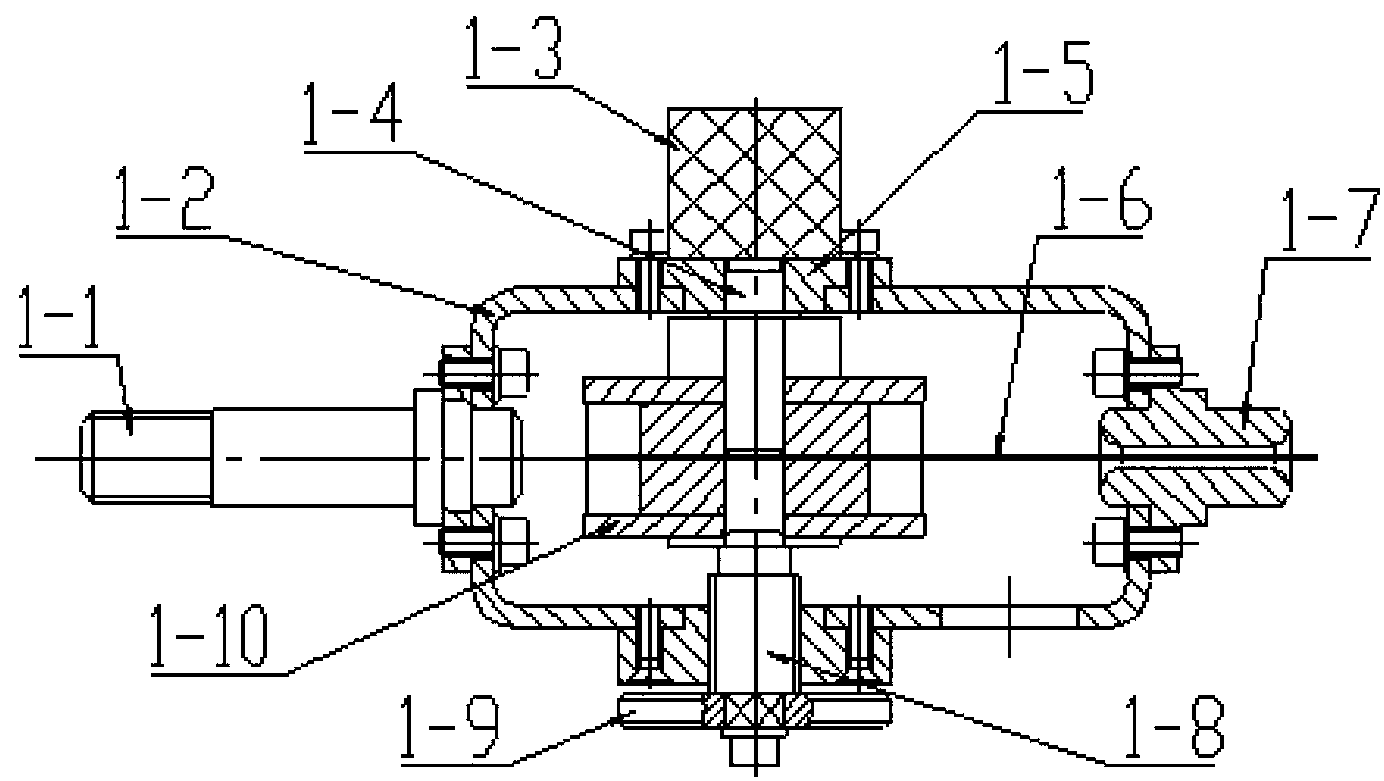

[0009] Pay-off tension precision balance device in tungsten wire rope winding machine, such as figure 1 As shown, the rotating body—the wire shuttle 1 on the disk 2 should be passively unwound under a certain tension, and the original tungsten wire 7 is pulled out from the wire release wheel in the wire shuttle 1 and then moves forward through the guide wheel 5, etc. , the tension control mechanism in wire shuttle 1 must be adjusted so that the tension of the tungsten wires released by each pay-off wheel is consistent, so as to ensure that the twisted tungsten wire rope 11 has a smooth surface and neat wire arrangement. The minimum diameter of the original tungsten wire 7 participating in the winding of the tungsten wire rope 11 is 0.05mm. The tension of the wire shuttle 1 is very important. If the tension is too high, it is easy to break the wire and stop the machine; If the tension of each wire is inconsistent, the wound tungsten wire rope will be loose and rough.

[0010] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com