Chain for improving transmission performance

A transmission performance and transmission chain technology, which is applied in the field of mechanical transmission, can solve the problems affecting the transmission performance, the diameter of the chain pin shaft cannot be too large, bending deformation, etc., and achieve the effect of improving the transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

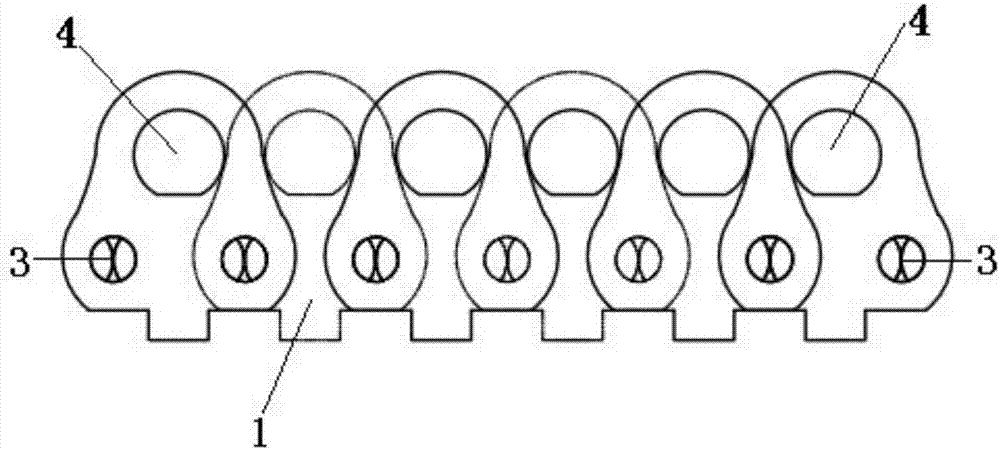

[0056] Please refer to the manual 1-5, attached Figure 7 , the present invention provides a chain with improved transmission performance, comprising: a transmission chain piece 1, a chain pin 3, and a support pin 4;

[0057] Among them, the transmission chain piece 1 is provided with a chain pin hole 5 and a support pin hole 6; the chain pin hole 5 is symmetrically arranged at both ends of one side of the transmission chain piece 1; the support pin hole 6 is located at the other side of the transmission chain piece 1 side;

[0058] The transmission chain piece 1 passes through the chain pin hole 5 and the support pin hole 6 respectively through the chain pin shaft 3 and the support pin shaft 4 to form a transmission chain array.

[0059] In order to further optimize the above technical solution, the support pin shaft 4 is connected to the transmission chain piece 1 by riveting or welding. The way of connecting the support pin shaft 4 and the transmission chain piece 1 is no...

Embodiment 2

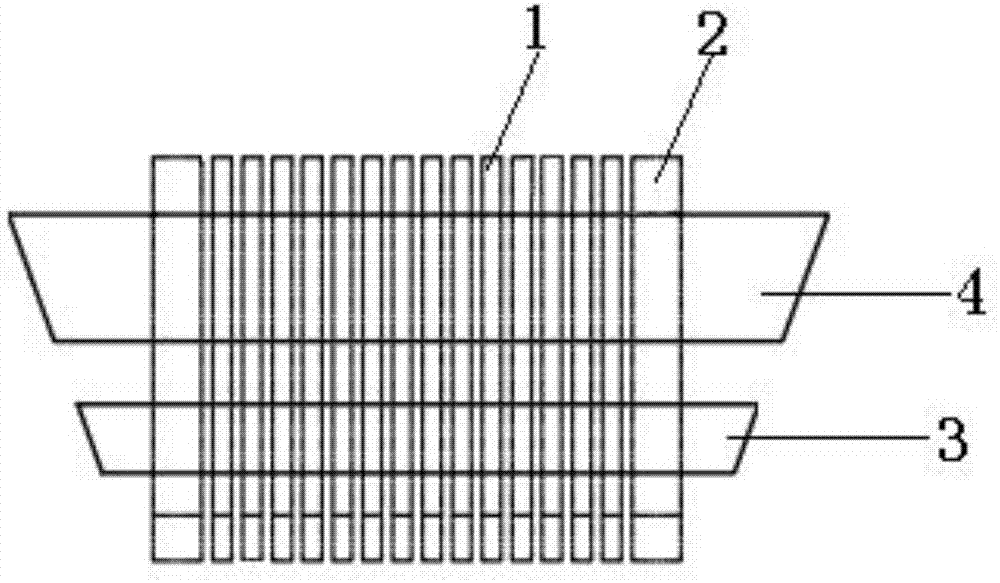

[0070] Please refer to the attached Figure 16 , a chain for improving transmission performance, comprising: a transmission chain piece 1, a U-shaped chain piece 2, and a chain pin shaft 3;

[0071] Among them, the U-shaped chain piece 2 and the transmission chain piece 1 are provided with chain pin holes 5; the chain pin holes 5 are respectively symmetrically arranged at both ends of one side of the U-shaped chain piece 2 and the transmission chain piece 1; the support pin holes 6 They are respectively located on the other side of the U-shaped chain piece 2 and the transmission chain piece 1;

[0072] The transmission chain piece 1 penetrates the chain pin hole 5 through the chain pin shaft 3 to form a transmission chain array;

[0073] Both ends of the transmission chain array are provided with a U-shaped chain piece 2, and the chain pins 3 of the transmission chain array pass through the chain pin holes 5 of the U-shaped chain piece 2 respectively to form a chain.

[0074...

Embodiment 3

[0079] On the basis of the technical solution of embodiment 1, in order to further optimize the above-mentioned technical solution, please refer to the attached Figure 3-5 , the support pin hole 6 is provided with an anti-rotation surface, and the anti-rotation surface includes an anti-rotation plane or an anti-rotation curved surface.

[0080] It should be noted that, when the support pin shaft is riveted or welded with the drive chain piece, the anti-rotation surface may not be provided.

[0081] In order to further optimize the above technical solution, the support pin shaft 4 is provided with a surface matching the anti-rotation surface.

[0082] exist image 3 Among them, the anti-rotation surface is set at the bottom of the support pin hole; Figure 4 Among them, the anti-rotation surfaces are respectively set on the top and bottom of the support pin hole; Figure 5 Among them, the anti-rotation surface is set on the top of the support pin hole.

[0083] When the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com