Low-permeability solid-free completion fluid

A technology without solids and completion fluids, applied in the direction of drilling compositions, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

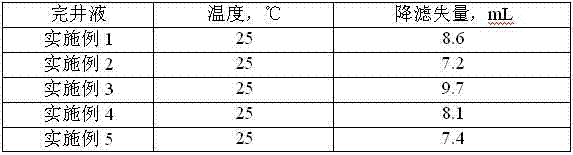

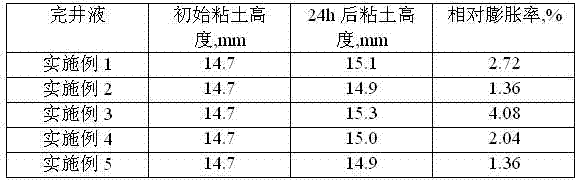

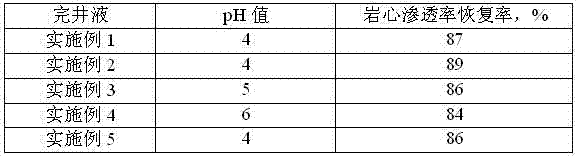

Examples

Embodiment 1

[0011] Example 3 Zinc bromide 65%, modified carboxymethyl starch 1%, diallyl dimethyl ammonium chloride 1%, nitrilotriacetic acid 0.05%, potassium nitrohumate 1% and sodium tungstate 0.5 %, the balance is water.

Embodiment 2

[0012] Example 4 Zinc chlorate 17%, zinc iodide 39%, modified carboxymethyl starch 1%, diallyl dimethyl ammonium chloride 1%, nitrilotriacetic acid 0.05%, potassium nitrohumate 1% % and sodium tungstate 0.5%, the balance is water.

Embodiment 3

[0013] Example 5 Zinc sulfate 15%, zinc chloride 30%, modified carboxymethyl starch 1%, diallyl dimethyl ammonium chloride 1%, nitrilotriacetic acid 0.05%, potassium nitrohumate 1% And sodium tungstate 0.5%, the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com