Dry processing technique for iron-containing steel slag

A technology of dry treatment and process, which is applied in the field of dry treatment process of iron-containing steel slag, can solve the problems of polluting groundwater resources, extensive treatment methods, occupying land resources, etc., to increase product added value, increase grinding efficiency, and system The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

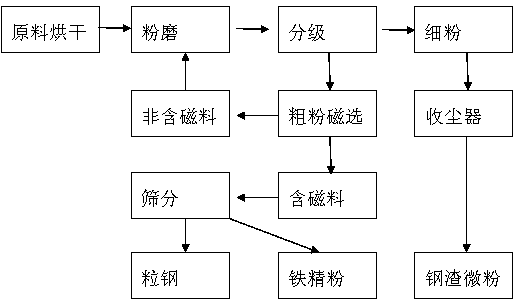

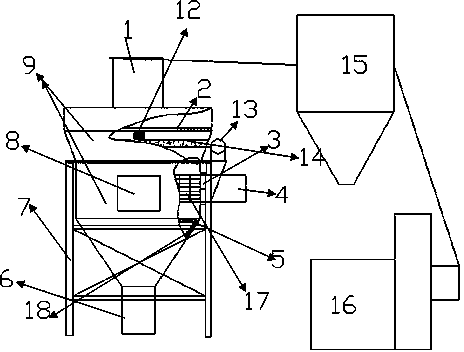

[0017] The present invention will be further described below in conjunction with the flowchart.

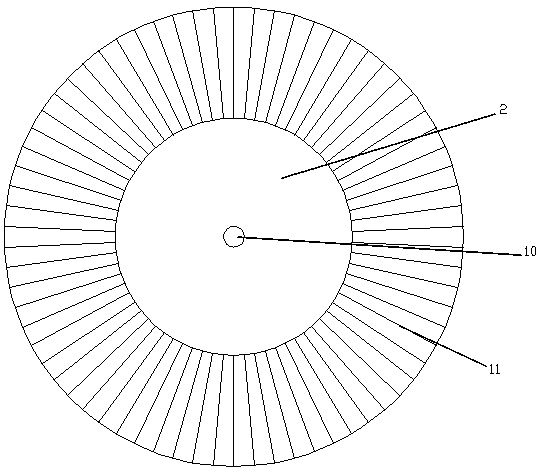

[0018] Iron-containing steel slag powder—the TFe content of the steel slag powder is about 15-30%. It is put into the raw material storage bin and sent to the rotary drum dryer for drying. After the steel slag powder is dried to a water content of ≤1.0%, the steel slag powder passes The belt conveyor is sent to the ball mill for dry grinding, and the steel slag powder after dry grinding enters the high-efficiency powder separator for classification, and the classification is >0.045mm and ≤0.045mm. Coarse powder with a particle size > 0.045mm is magnetically separated by a belt conveyor through a dry-type permanent magnetic cylinder magnetic separator. After magnetic separation by the magnetic separator, it is classified into magnetic material and non-magnetic material, and the non-magnetic material is directly returned to the mill. Carry out re-grinding; the magnetic materials are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com