Method for increasing recovery rate of converter gas

A converter gas, recovery technology, applied in the direction of manufacturing converters, etc., to achieve the effect of increasing recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

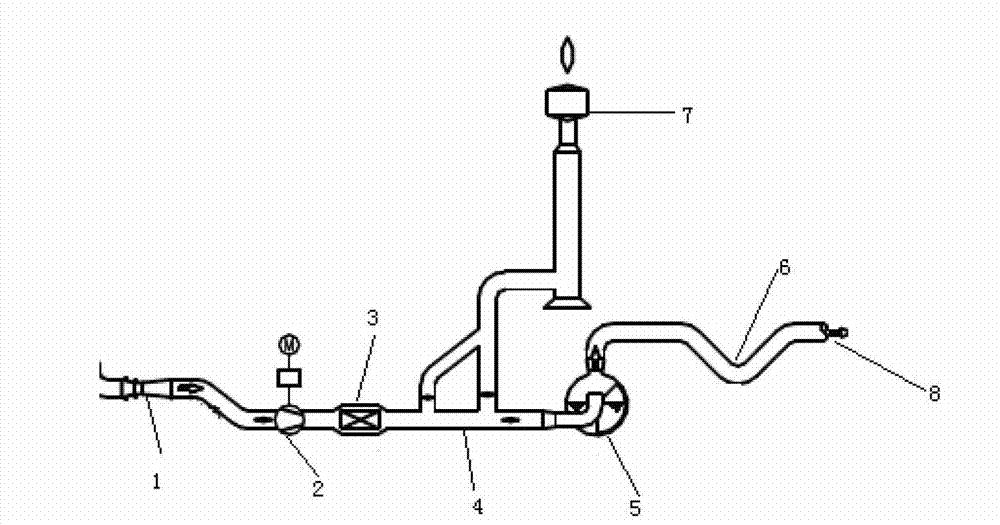

Image

Examples

Embodiment 1

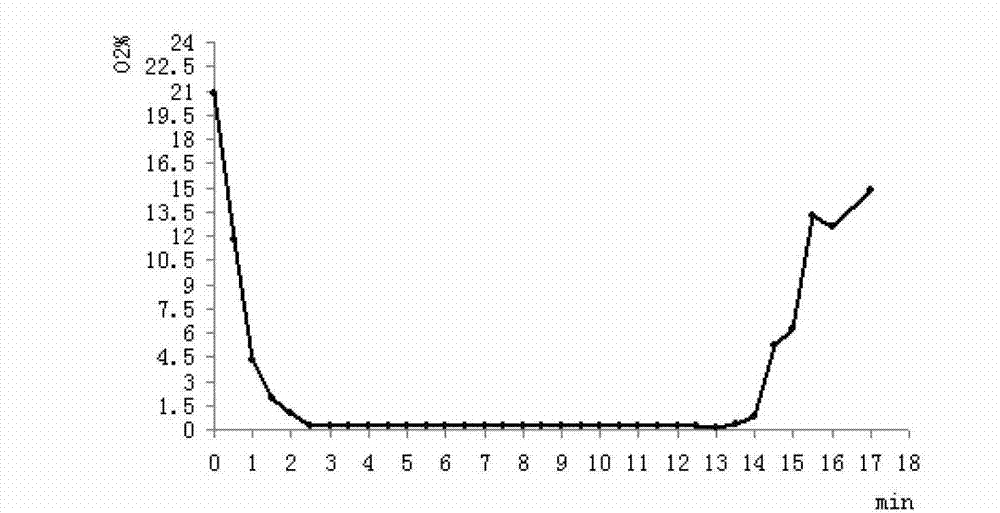

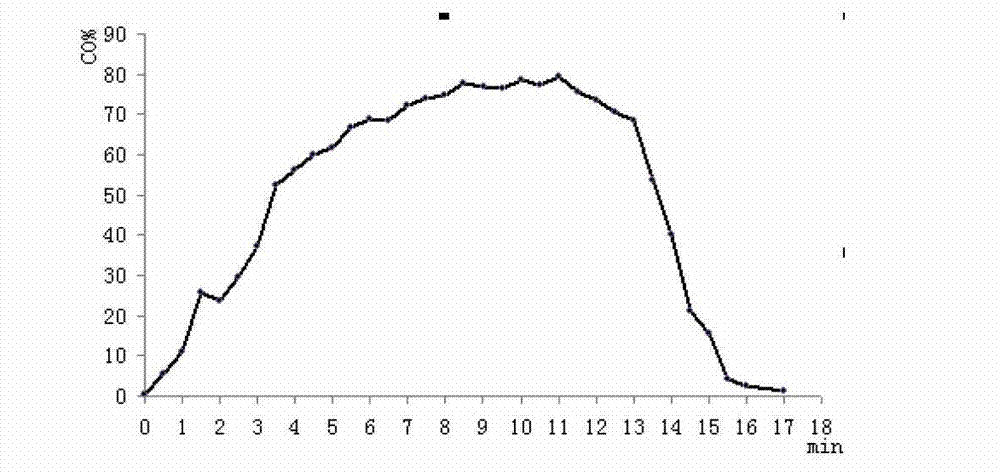

[0037] The furnace number is 2P05486:

[0038] 1. When the furnace steel is blown to 2′36″, the blowing of the oxygen lance is below the oxygen opening point, the skirt is at a low position, and there is no fault alarm for the three-way valve and the water reverse valve; the compressed air pressure is 0.493MPa; The through valve is closed; the fan speed is 1350r / min; the oxygen content is 0.08wt%; the CO content is 37.2wt%; the gas cabinet is 60100m 3 ;It takes 2.6 minutes to blow the lance, and the above conditions meet the conditions for the automatic gas recovery of the first lance lowering, and the gas recovery starts automatically.

[0039] 2. When the blowing reaches 4′35″, the oxygen lance blowing is below the oxygen opening point, the cover skirt is at a high position, and the three-way valve and water reverse valve have no fault alarm; the compressed air pressure is 0.460MPa; the bypass valve is at Closed state; fan speed 1350r / min; oxygen content 0.06wt%; CO content...

Embodiment 2

[0043] The furnace number is 1O07321:

[0044] 1. When the furnace steel is blown to 2′46″, the blowing of the oxygen lance is below the oxygen opening point, the cover skirt is at a low position, and there is no fault alarm for the three-way valve and the water reverse valve; the compressed air pressure is 0.466MPa; The through valve is closed; the fan speed is 1300r / min; the oxygen content is 0.04wt%; the CO content is 47wt%; the gas cabinet is 30900m 3 ; The blowing process lasted 2.77 minutes, and the above conditions met the conditions for automatic gas recovery in the first lowering of the lance, and gas recovery began automatically.

[0045] 2. When the blowing reaches 5'52", the blowing of the oxygen lance is below the oxygen opening point, the cover skirt is at a high position, and the three-way valve and water reverse valve have no fault alarm; the compressed air pressure is 0.459MPa; the bypass valve is at Closed state; fan speed 1300r / min; oxygen content 0.04wt%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com