Self-cutting cotton rolling device

A cotton rolling device and self-cutting technology, which can be used in winding mechanism, textile and paper making, fiber processing, etc., can solve the problems of untidy edges of carding tires, affect the production of quilts, waste manpower, etc., and achieve good quality and cutting Accurate and safe results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described:

[0016] This self-cutting cotton rolling device is installed at the rear of the carding machine and is used to make carding tires.

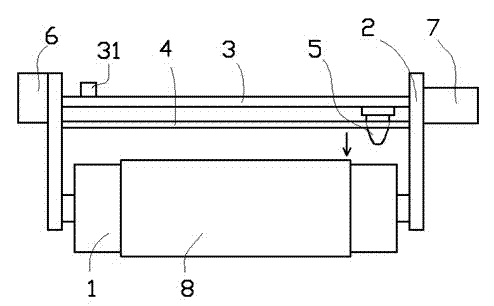

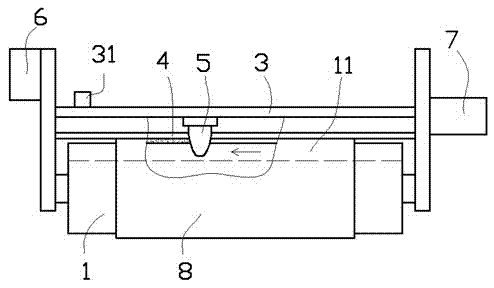

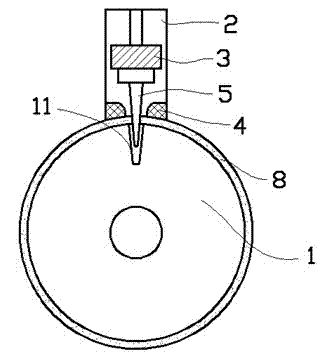

[0017] Such as figure 1 and image 3 As shown in the embodiment, the self-cutting cotton rolling device includes a cotton roll 1, a support 2, a horizontal rail 3, a cotton pressing rod 4, and a cutter 5; the support 2 is installed at both ends of the cotton roll 1; The horizontal rail 3 and the pressing rod 4 are fixed on the support 2, and its axis is parallel to the axis of the cotton roll 1, and can be moved along the support 2 under the control of the longitudinal motor 6; the cutter 5 is mounted on the The horizontal rail 3 is controlled by the horizontal motor 7 to move left and right along the direction of the horizontal rail 3; the cotton drum 1 is designed with a cutting groove 11 corresponding to the position of the cutter; The cutters 5 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com