Coating process for waterproof and anti-ultraviolet fabric

An anti-ultraviolet and coating technology, applied in textiles and papermaking, dumping textile material treatment, fiber treatment, etc., can solve the problems of unfavorable water vapor emission, influence of fabric style, poor washing fastness of anti-ultraviolet function, etc., and achieve good waterproof UV protection performance, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

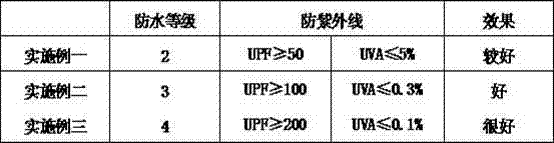

Examples

Embodiment 1

[0021] Embodiment one: described step A: the PA black slurry that adopts when coating primer is formed PA black slurry primary glue after the polyacrylate resin of mass percentage 23% and 77% toluene are stirred in mixer for 5 minutes, then adds PA The black pulp with 10% of the total mass of primary glue, and the bridging agent with 3% of the total mass of PA primary glue are stirred again for 5 minutes to form PA black pulp, and the stirring thermometer is 10°C;

[0022] Said step B: the PA bright silver glue used when coating PA bright silver glue is formed by the polyacrylate resin of 18% by mass percentage and 82% toluene in the mixer after stirring for 5 minutes to form the initial glue of PA bright silver glue, and then add PA 6080 bright silver with a total mass of 16% of the initial glue of bright silver glue is stirred again for 5 minutes to form PA bright silver glue, and the thermometer is stirred at 10°C;

[0023] Described step C: the PU pearlescent glue that ado...

Embodiment 2

[0025] Embodiment two: described step A: the PA black pulp that adopts when coating primer is formed PA black pulp primary glue after the polyacrylate resin of mass percentage 27% and 73% toluene are stirred in mixer for 15 minutes, then add PA The black pulp with 20% of the total mass of primary glue, and the bridging agent with 5% of the total mass of PA primary glue are stirred again for 15 minutes to form PA black pulp, and the stirring thermometer is 40°C;

[0026] Said step B: the PA bright silver glue used when coating the PA bright silver glue is formed by the polyacrylate resin with a mass percentage of 22% and 78% toluene in a mixer for 15 minutes to form the PA bright silver glue primary glue, and then add PA The 6080 bright silver with 20% of the total mass of the initial glue of the bright silver glue is stirred again for 15 minutes to form a PA bright silver glue, and the stirring thermometer is 40°C;

[0027] Described step C: the PU pearlescent glue that adopts...

Embodiment 3

[0029] Embodiment three: described step A: the PA black pulp that adopts when coating primer is formed PA black pulp primary glue after the polyacrylate resin of mass percentage 25% and 75% toluene are stirred in mixer for 10 minutes, then add PA The black pulp with 15% of the total mass of primary glue, and the bridging agent with 4% of the total mass of PA primary glue are stirred again for 10 minutes to form PA black pulp, and the stirring thermometer is 25°C;

[0030] Said step B: the PA bright silver glue used when coating PA bright silver glue is made of polyacrylate resin with a mass percentage of 20% and 80% toluene in a mixer for 10 minutes to form a PA bright silver glue primary glue, and then add PA The 6080 bright silver with 18% of the total mass of the initial glue of bright silver glue is stirred again for 10 minutes to form PA bright silver glue, and the temperature of the stirring thermometer is 25°C;

[0031]Said step C: the PU pearlescent glue used when coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com