Electrohydraulic controls for hydraulic distributors

A technology for a hydraulic distributor and a control device, which is applied in the hydraulic field, can solve problems such as the inability to control the hydraulic distributor normally, and achieve the effects of improving the response sensitivity and reliability of use, compact structure and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

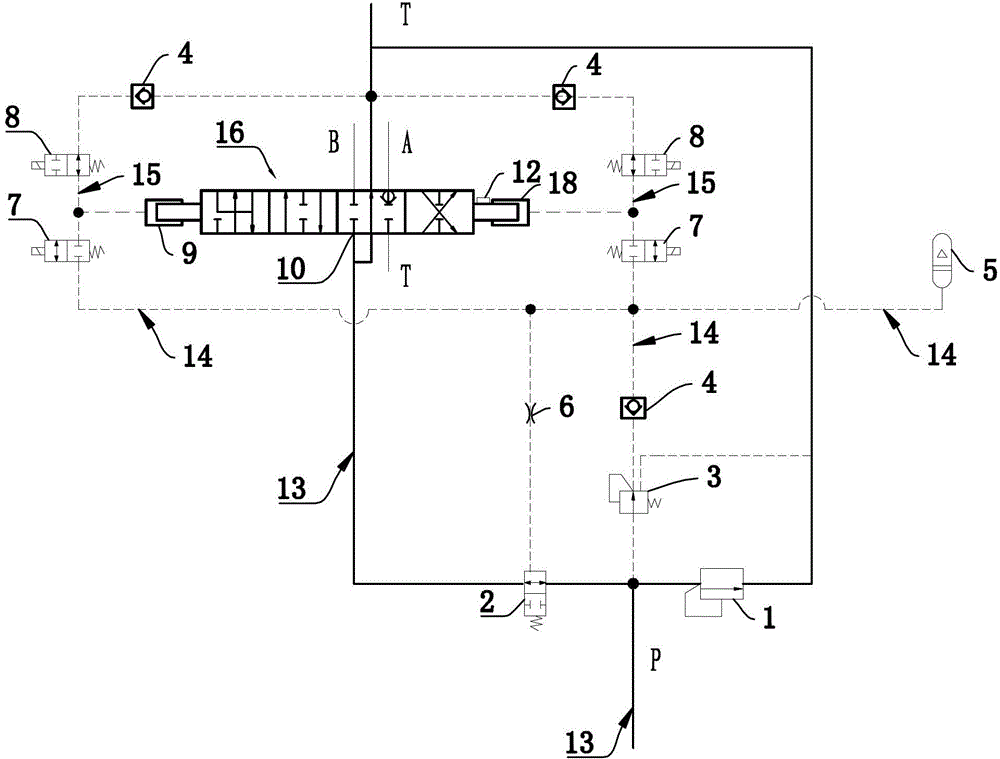

[0019] figure 1 An electro-hydraulic control device for a hydraulic distributor of a tractor suspension mechanism is shown, and an oil inlet 10 of a hydraulic distributor 16 is connected to a host oil circuit 13 . The two ends of the valve stem of the hydraulic distributor 16 are respectively connected to the first hydraulic push rod 9 and the second hydraulic push rod 18, and the first hydraulic push rod 9 and the second hydraulic push rod 18 are respectively connected to the hydraulic distributor through an electromagnetic switch valve a8. The oil return circuit, the first hydraulic push rod 9 and the second hydraulic push rod 18 are respectively connected to an energy storage oil circuit 14 through an electromagnetic switch valve b7, the energy storage oil circuit 14 is provided with an accumulator 5, and the host oil circuit 13 passes through The pressure reducing valve 3 and the one-way valve 4 connected in sequence are connected to the energy storage oil circuit 14, and ...

Embodiment 2

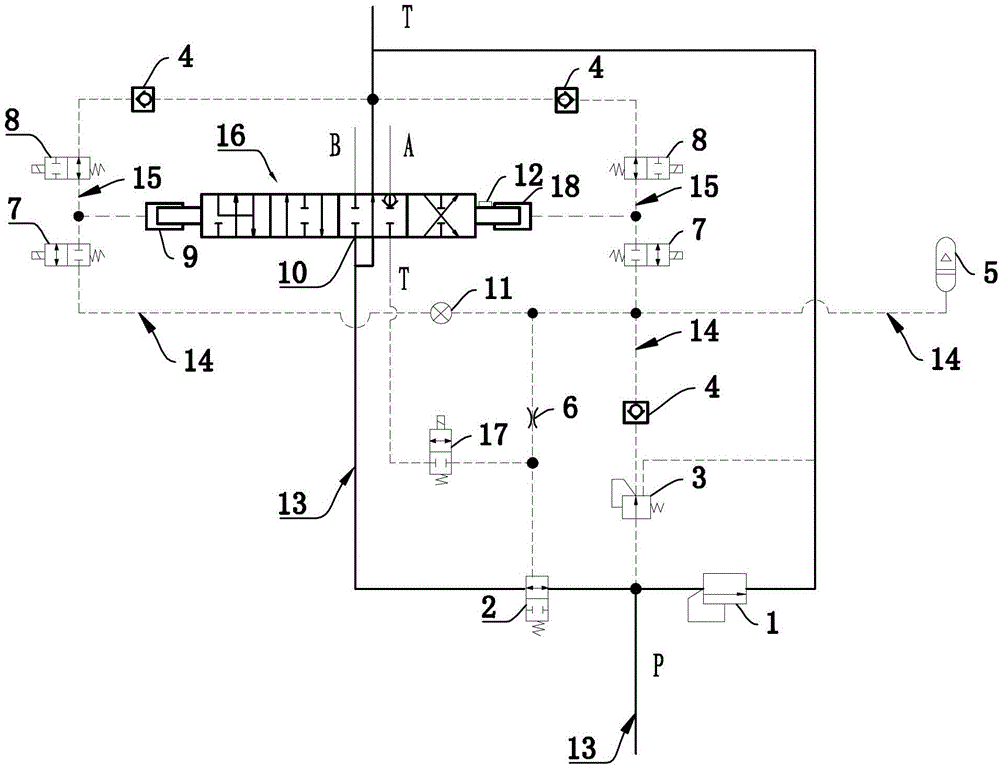

[0028] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that an electromagnetic switch valve c17 is set between the oil return circuit of the hydraulic distributor 16 of the hydraulic control port of the two-position two-way hydraulic control valve 2, and the storage A pressure switch 11 is arranged on the energy oil passage 14, and the pressure switch 11 is electrically connected with the solenoid valve c17. The effect of such setting is to further improve the response sensitivity and reliability of the system.

[0029] When the pressure in the energy storage oil circuit 14 drops to the set value, the pressure switch 11 drives the electromagnetic switch valve c17 to act, so that the hydraulic control port of the two-position two-way hydraulic control valve 2 is connected to the return oil circuit. 6, the oil pressure of the hydraulic control port drops instantly, and the two-position two-way hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com