Falling film evaporating pipe with netlike outer surface

A falling film evaporation, outer surface technology, applied in tubular elements, lighting and heating equipment, heat exchange equipment, etc. Improve the surface evaporation heat transfer coefficient, reduce the thickness of the liquid film, and avoid the effect of drying up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

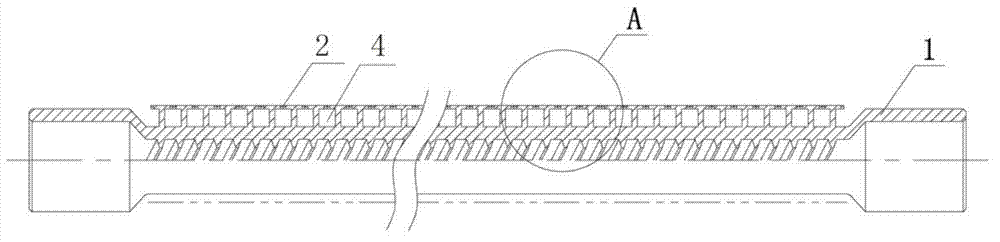

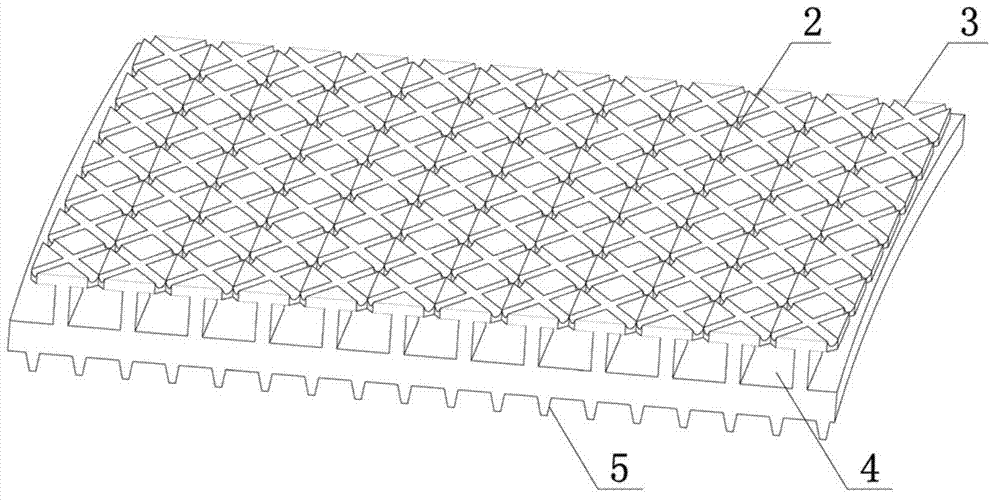

[0020] Example: such as figure 1 As shown, the falling film evaporation heat exchange tube of this embodiment includes a tube body 1 with a central lumen, and the two ends of the tube body are light sections. After the end plates on both sides of the device, it can be tightly fixed with the end plates. The tubular body 1 is provided with a cavity 4 that is distributed in a spiral shape along the axial direction of the tubular body, with a height of 0.4-0.7 mm and a width of 0.3-0.6 mm (the height refers to the cavity in the figure 1 The length in the up and down direction, the width is the cavity in figure 1 length in the left-right direction). The outer surface of the tube body 1 is provided with a plurality of small holes 2 communicating with the cavity 4 .

[0021] In this embodiment, grid-like microchannels 3 are also provided on the outer surface of the tube body 1 . In this way, during work, part of the liquid sprayed onto the heat exchange tube body 1 will flow into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com