Fusion structure of missile wing connection lug channel and missile body

A technology for connecting ears and wings, applied to projectiles, offensive equipment, weapon types, etc., can solve problems such as uneven force, excessive force on fasteners, difficulty in ensuring ear slots and body, and reduce Effects of interfering with drag and wave drag, increasing wing lift surface, and improving wing load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0015] The following embodiments are only used to illustrate the present invention, and are not used to limit the protection scope of the present invention.

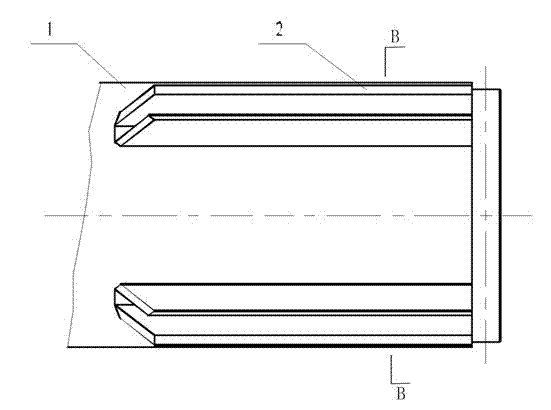

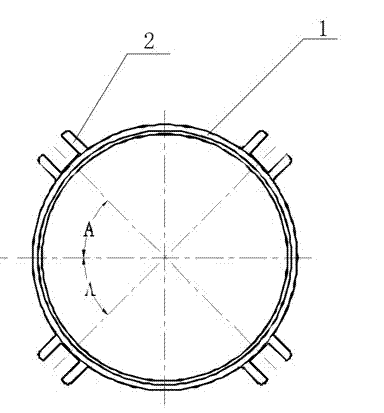

[0016] Such as figure 1 with 2 As shown, an elastic wing connecting ear groove and elastic body fusion structure of the present invention, the fusion structure adopts the elastic body 1 and the ear groove 2 to be directly CNC integrated and formed. The elastic body 1 is made of aluminum, and the central axis of the ear groove 2 is The included angle of the axis of the projectile body is A, A=45°±12'.

[0017] The bullet body 1 uses a special-shaped aluminum tube blank with ribs. The inner and outer diameter coaxiality of the bullet body 1 is required to be 0.08. The parts are processed by the overall CNC machine, the dimensional accuracy is easy to control, the process is simple, and the surface quality is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com