Lens mounting structure of eyeglass frame

A lens installation and spectacle frame technology, which is applied in the directions of glasses/safety glasses, glasses/goggles, lens components, etc., can solve the problems of lens falling, not being able to get a good field of view, narrow field of view, etc. High field of view and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

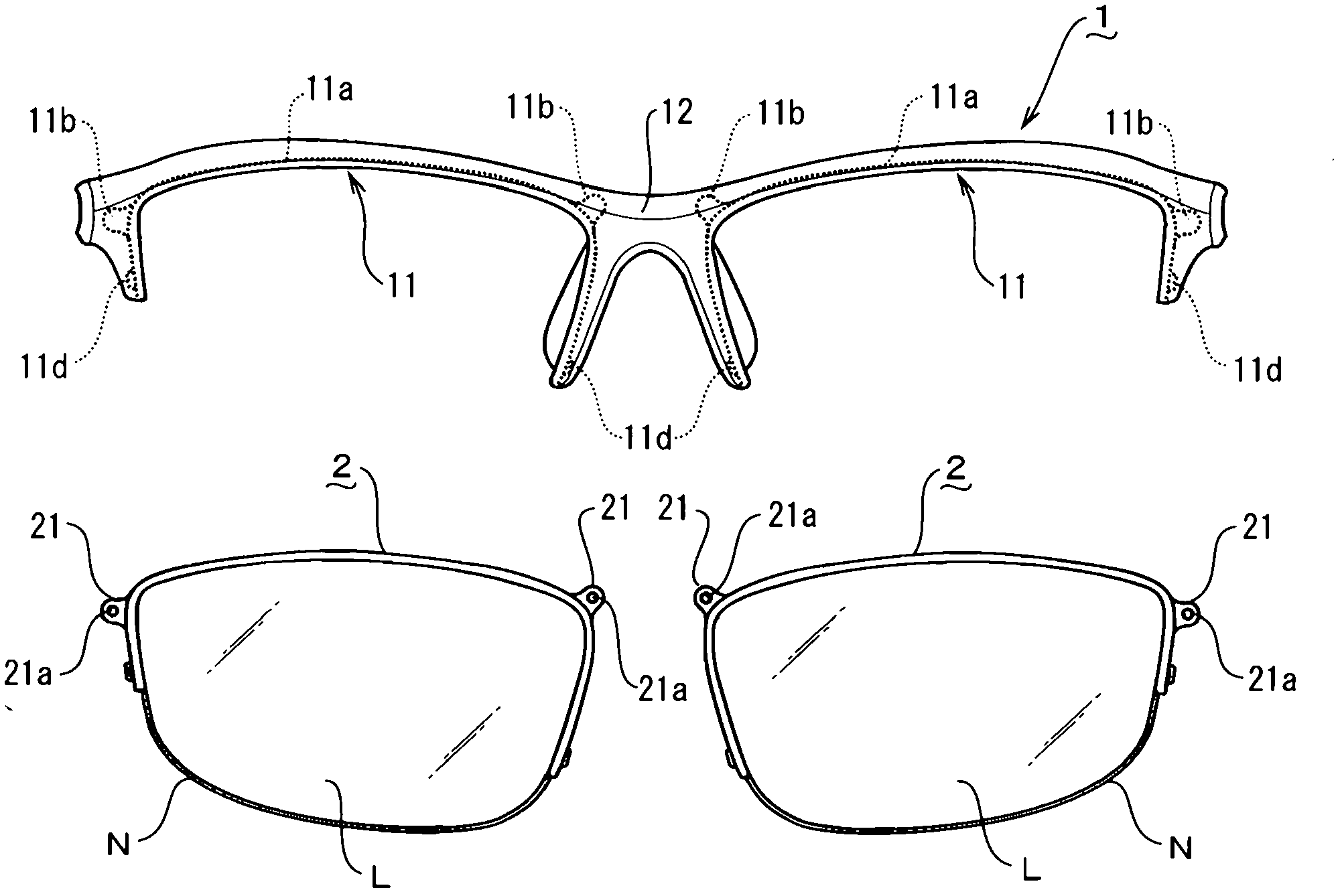

[0038] based on Figure 1 to Figure 4 , to illustrate Embodiment 1 of the present invention. In addition, in these figures, the part indicated by the code|symbol 1 is the front frame which connects temple T, T on both sides, and the part indicated by the code|symbol 2 is an inner lens ring.

[0039] First, in Example 1, the left and right bezel covers 11, 11 having inner grooves 11a are provided on the half bezel-type front frame 1 (material: polyamide resin), and inside these bezel covers 11 The inner lens rings 2 and 2 (material: stainless steel) with the lens L fixed by the flexible wire N are installed on the groove 11a, forming the lens mounting part of the spectacle frame F (see figure 1 , figure 2 ).

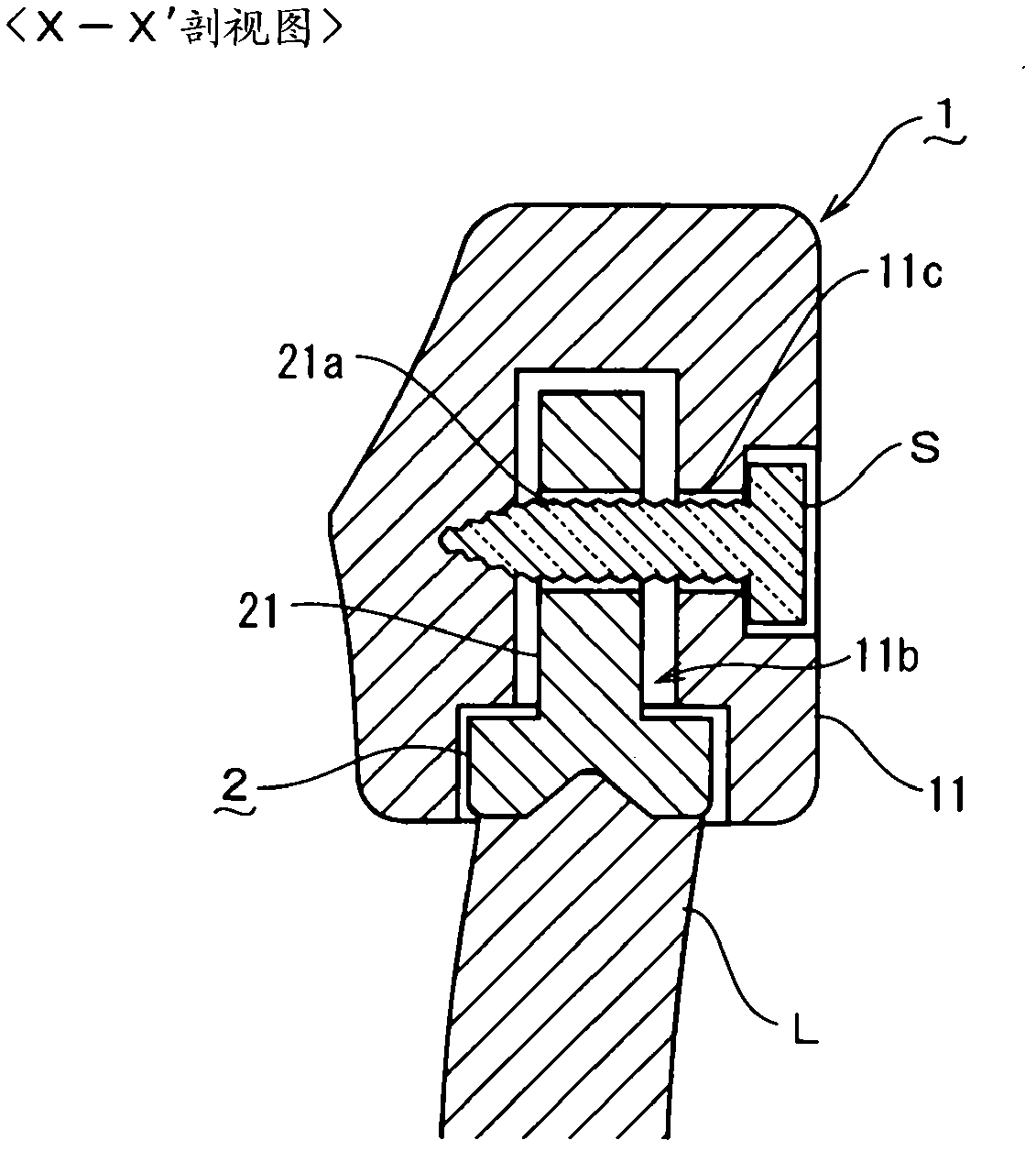

[0040] In addition, regarding the bezel cover 11 and the inner bezel 2 of the front frame 1, the inner groove 11a of the bezel cover 11 is provided with a recess 11b formed locally deeper than the inner groove 11a. On the other hand, Protrusions 21 are provided at pr...

Embodiment 2

[0048] Next, based on Figure 5 , Embodiment 2 of the present invention is described as follows. In this second embodiment, the protrusion 21' of the inner lens ring 2 inserted into the concave portion 11b on the temple side of the lens ring cover 11 of the front frame 1 is made into a horizontal hook shape without an insertion hole. .

[0049] And, thus, if the protrusion 21 ′ of the inner lens rim 2 arranged laterally is inserted into the concave portion 11 b of the lens rim cover 11 and locked, only by inserting the protrusion 21 ′ of the lens rim cover 11 on the nose bridge side The upward protruding part 21 is fixed with a screw S at one position, so that the inner mirror ring 2 can be installed on the mirror ring cover 11 .

Embodiment 3

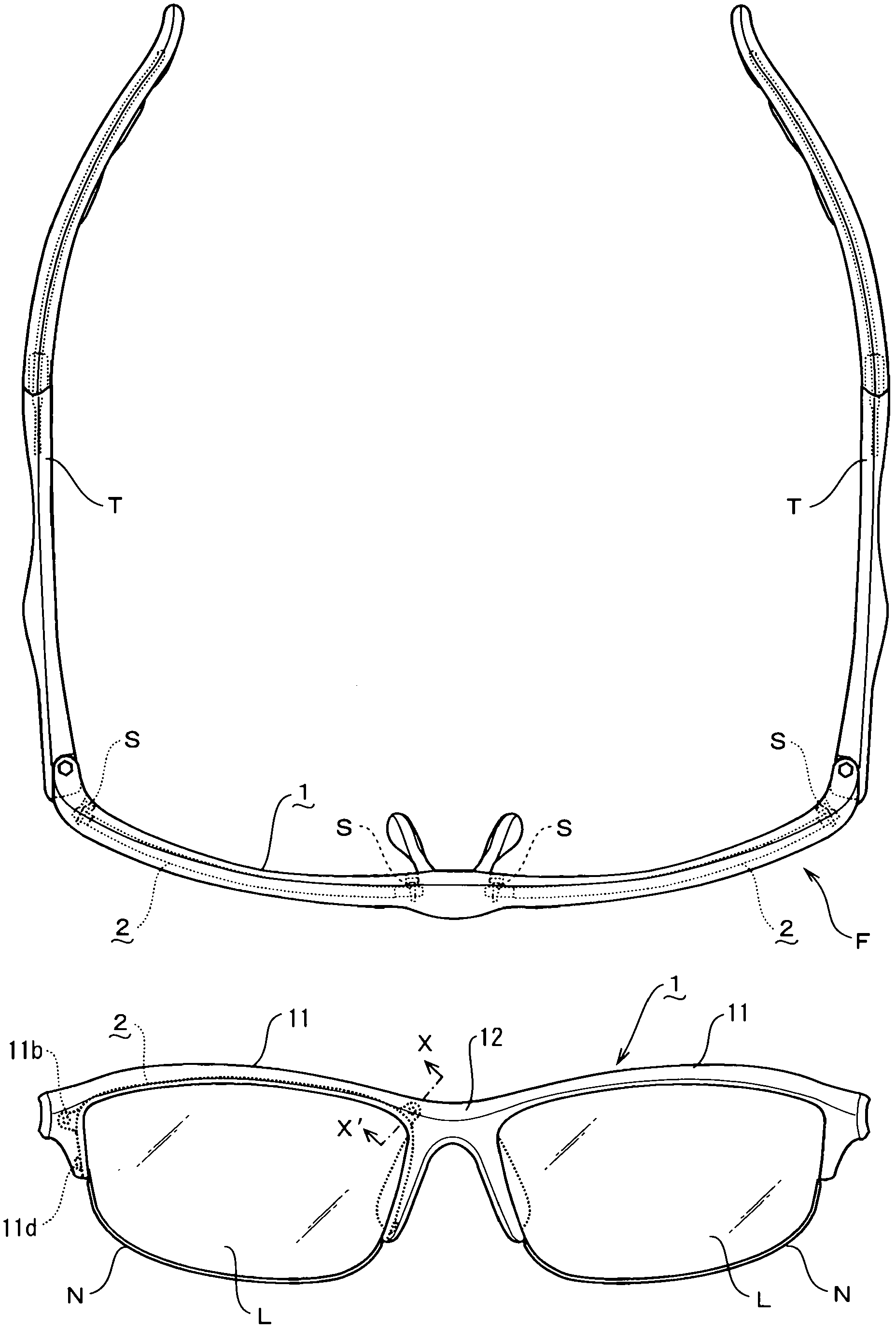

[0051] Next, based on Figure 6 , Embodiment 3 of the present invention will be described below. In this embodiment 3, a bezel cover 11 having an inner groove 11a is formed on the brow bar-shaped front frame 1 over the left and right, and the lens ring cover 11 of the front frame 1 is attached to the bezel cover 11 to which the left and right lenses L, L can be attached. The inner mirror ring 2 with the nose bridge 22 constitutes the lens mounting part of the spectacle frame F.

[0052] In addition, on the mirror cover 11 of the front frame 1, recessed parts 11b, 11b... . . . , the protrusions 21, 21... at three positions on the inner lens ring 2 are fixedly connected in the inserted state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com