How to make an electromagnet

A production method and electromagnet technology, applied in the direction of inductance/transformer/magnet manufacturing, electromagnet, circuit, etc., to achieve the effect of increasing suction, eliminating deviation, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A manufacturing method of an electromagnet, which comprises the following steps:

[0033] (1) Prepare 8 pieces of 1mm E-shaped electrical pure iron sheet, and the E-shaped electrical pure iron sheet uses DT4E;

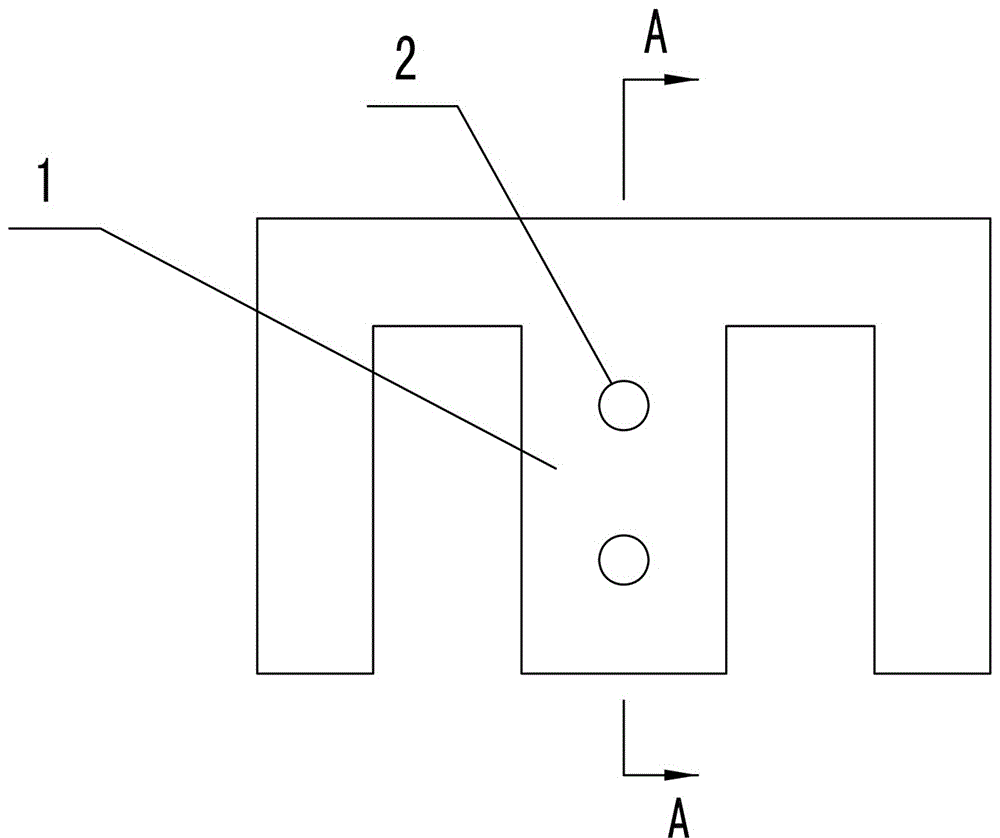

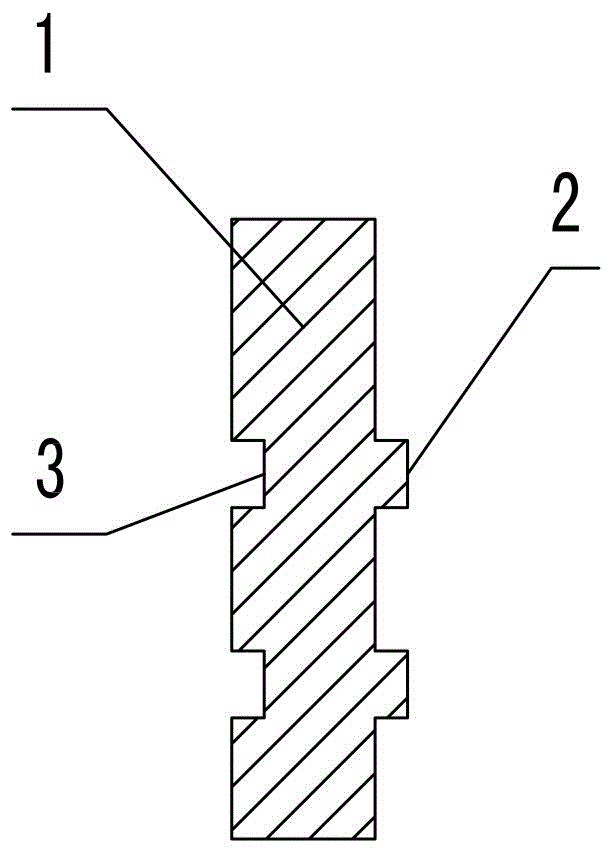

[0034] (2), such as figure 1 , figure 2 , Punch out two bosses 2 and two grooves 3 at the same position on the middle column 1 of each E-shaped electrical pure iron sheet;

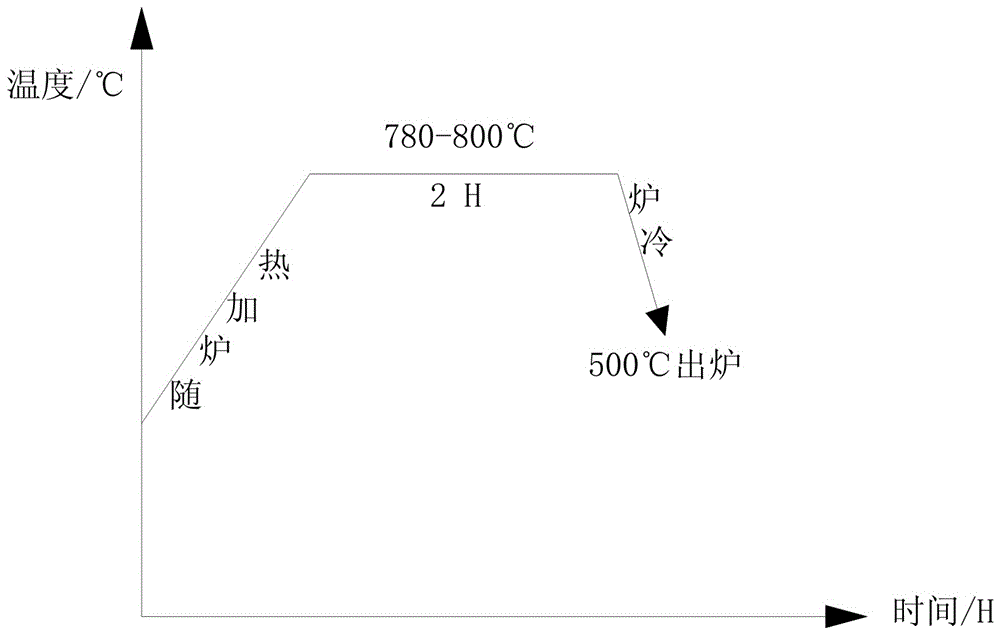

[0035] (3) Heat-treat the E-shaped electrical pure iron sheet;

[0036] (4) Stack 8 E-shaped electrical pure iron sheets together and put them into the skeleton to ensure that the suction surface of the E-shaped electrical pure iron sheet has a flatness of 0.02, and the boss of the lower E-shaped electrical pure iron sheet 2. Insert it into the groove 3 of an E-shaped electrical pure iron sheet above, and form the electrical pure iron sheet to obtain a semi-finished electromagnet;

[0037] (5) Blackening treatment: Clean and dry the surface of the obtained electromagnet semi-finished p...

Embodiment 2

[0042] A manufacturing method of an electromagnet, which comprises the following steps:

[0043] (1) Prepare 6 pieces of 1.2mm E-shaped electrical pure iron sheet, and the E-shaped electrical pure iron sheet uses DT4E;

[0044] (2) Punch out a boss and a groove at the same position on the middle column of each E-shaped electrical pure iron sheet;

[0045] (3) Heat-treat the E-shaped electrical pure iron sheet;

[0046] (4) Stack 6 E-shaped electrical pure iron sheets together and put them into the skeleton to ensure that the suction surface of the E-shaped electrical pure iron sheet has a flatness of 0.01, and the boss of the lower E-shaped electrical pure iron sheet Insert it into the groove of an E-shaped electrical pure iron sheet above, and the electrical pure iron sheet is formed to obtain a semi-finished electromagnet;

[0047] (5) Blackening treatment: Clean and dry the surface of the semi-finished electromagnet, put it into the blackening solution and stir for 50 min...

Embodiment 3

[0052] A manufacturing method of an electromagnet, which comprises the following steps:

[0053] (1) Prepare 10 pieces of 0.8mm E-shaped electrical pure iron sheets, and the E-shaped electrical pure iron sheets use DT4E;

[0054] (2) Punch out a boss and a groove at the same position on the middle column of each E-shaped electrical pure iron sheet;

[0055] (3) Heat-treat the E-shaped electrical pure iron sheet;

[0056](4) Stack 10 E-shaped electrical pure iron sheets together and put them into the skeleton to ensure that the suction surface of the E-shaped electrical pure iron sheet has a flatness of 0.02, and the boss of the E-shaped electrical pure iron sheet below Insert it into the groove of an E-shaped electrical pure iron sheet above, and the electrical pure iron sheet is formed to obtain a semi-finished electromagnet;

[0057] (5) Blackening treatment: Clean and dry the surface of the obtained electromagnet semi-finished product, put it into the blackening solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com