Micro speaker module

A micro-speaker, injection molding technology, applied in the direction of microphones, loudspeakers, sensors, etc., can solve the problems of increasing friction, reducing thickness, reducing volume, etc., to reduce the overall thickness, reliable area, and prevent the reduction of the emitted volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the microspeaker module of the present invention will be described in detail with reference to the drawings.

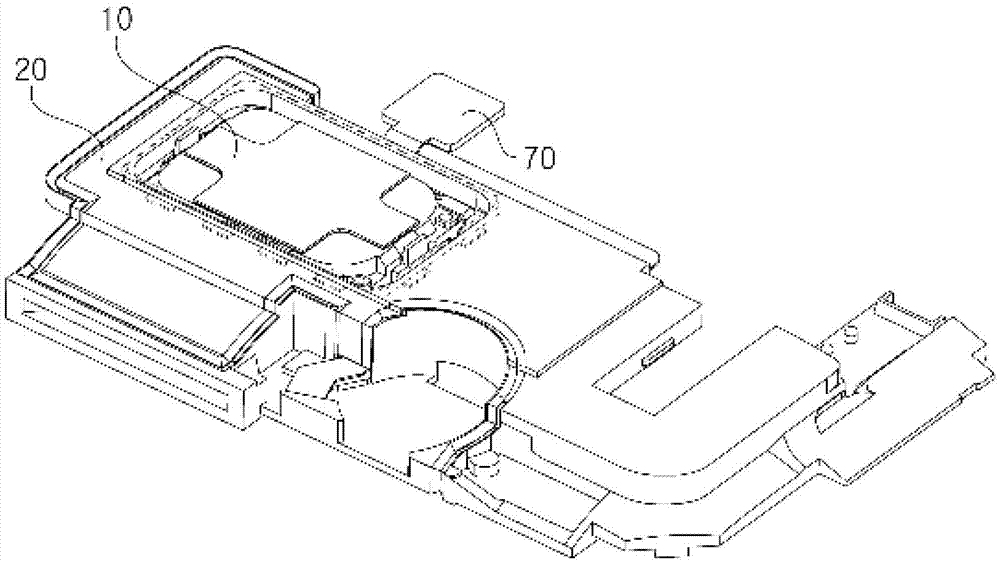

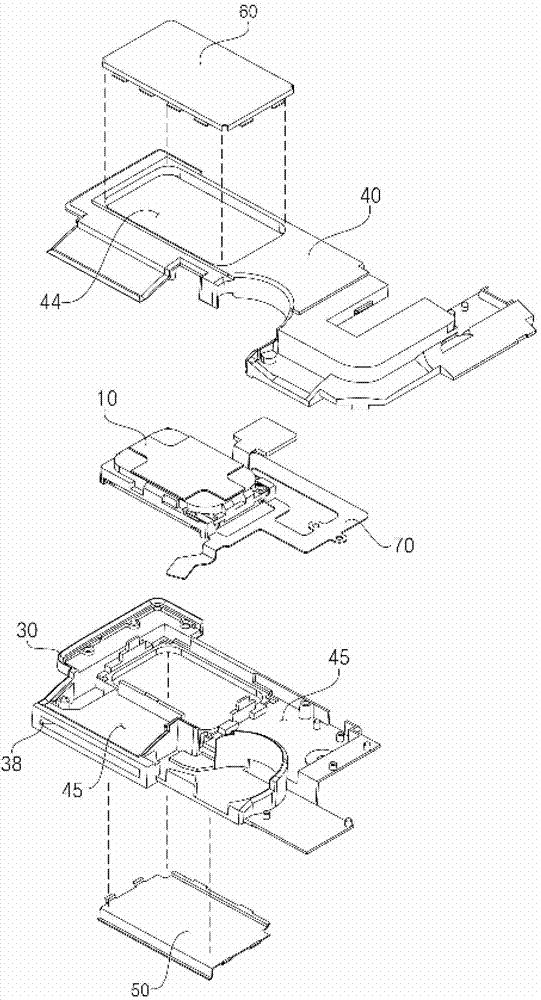

[0045] Such as figure 1 As shown, the micro-speaker module of the present invention includes a micro-speaker 10 and a casing 20 supporting the micro-speaker 10 . Unexplained reference numeral 70 is a terminal portion connected to the microspeaker 10 .

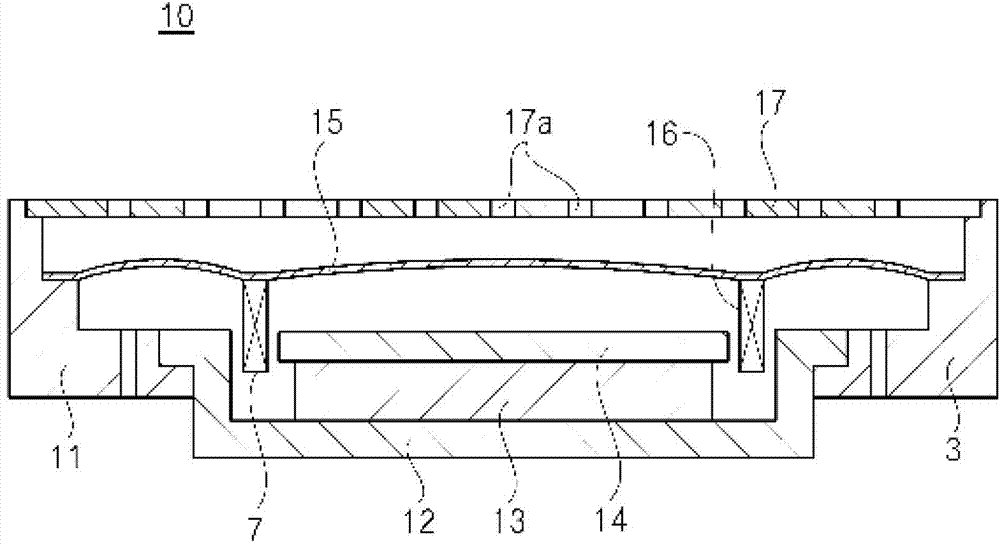

[0046] Such as figure 2 As shown, the micro-speaker 10 includes: a lower casing 11 injection-molded with synthetic resin or the like; a yoke member 12, a magnet 13, a plate 14, and a vibration plate 15 installed in the lower casing 11 in sequence; a voice coil fixed on the bottom surface of the vibration plate 15 16. The upper top cover 17, which protects the vibration plate 15 and is formed with a plurality of sound emitting ports 17a so that the sound generated from the front of the vibration plate 15 can be emitted smoothly.

[0047] At this time, the lower cabinet 11 has a structure that ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com