Water-cooling loop of high frequency cavity for small medical circular accelerator

A cyclotron, high-frequency cavity technology, applied in magnetic resonance accelerators, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of high-frequency cavity thermal deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

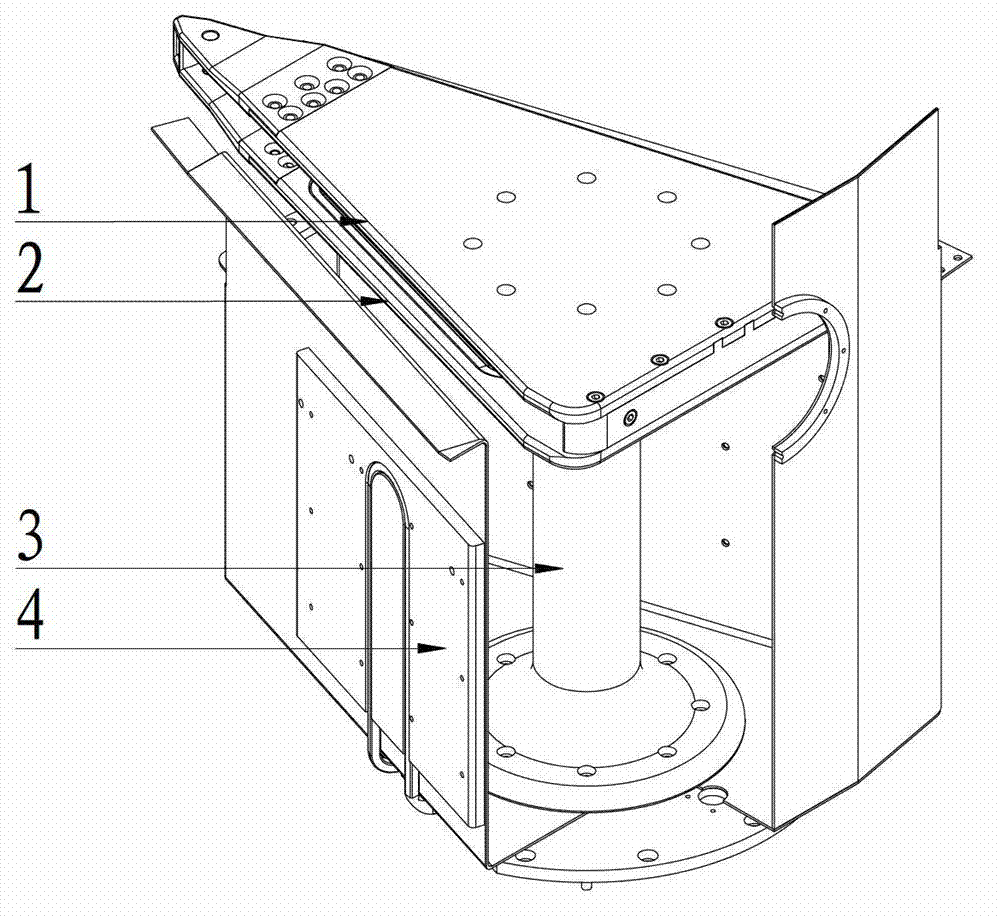

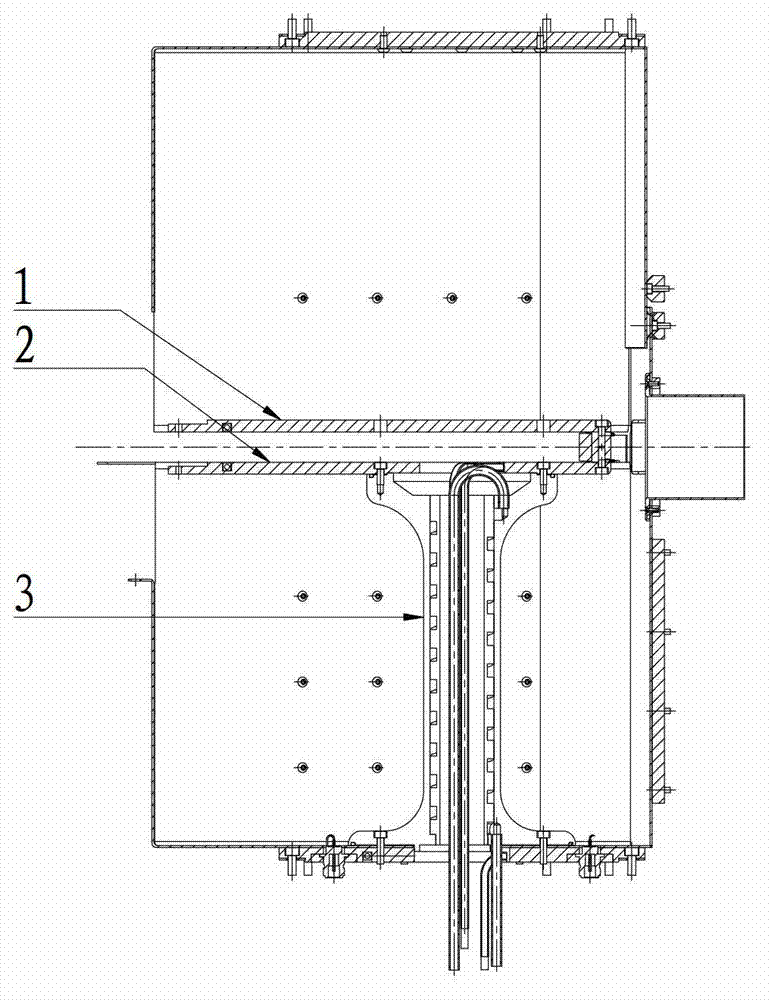

[0023] Such as figure 1 and 2 As shown, the small-sized medical cyclotron high-frequency cavity water cooling circuit of the present invention includes an upper D-plate water-cooling circuit, a lower D-plate water-cooling circuit, a high-frequency inner rod water-cooling circuit, and a high-frequency cavity two sides and a bottom surface water-cooling circuit. The specific structure is as follows:

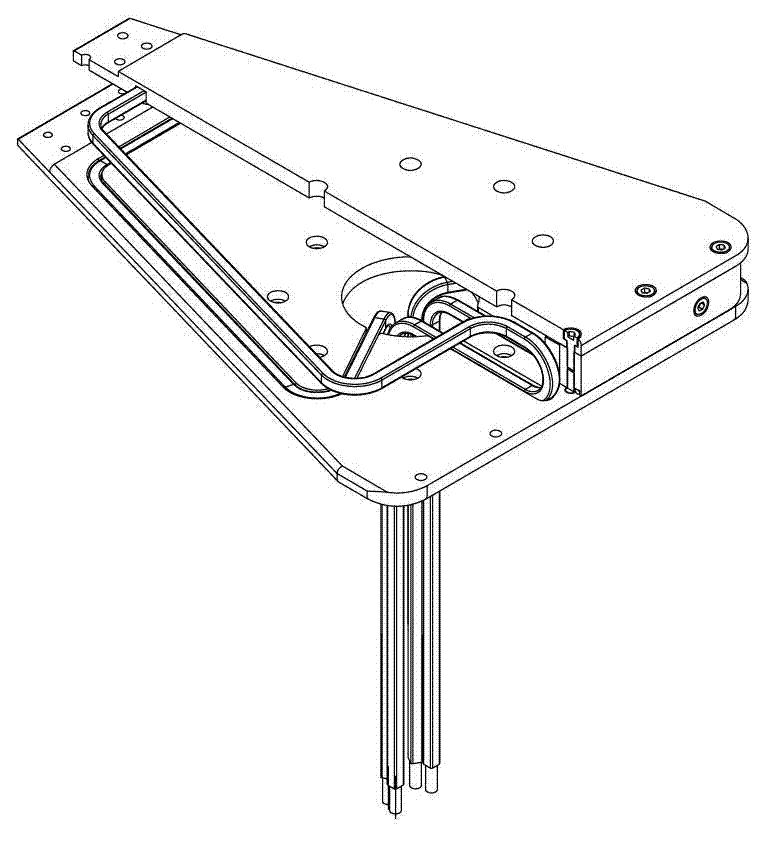

[0024] a. The water cooling circuit of the upper D board (refer to figure 1 and 3 )

[0025] Cooling grooves are processed at the edge of the lower surface of the upper D-plate 1 where the heat is accumulated and concentrated, and the cooling water pipes are buried. The center hole, and then through the center hole of the lower D board 2, the center hole of the high-frequency inner rod 3 and the reserved hole of the main magnet to lead out the accelerator;

[0026] b. The water cooling circuit of the lower D board (refer to figure 1 and 4 )

[0027] Cooling grooves are proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com