Method of double-sided friction stir welding of metal plates with gaps in butt joints

A technology of friction stir and joining method, which is applied in the direction of metal processing, metal processing equipment, welding/welding/cutting items, etc., and can solve problems such as layer difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

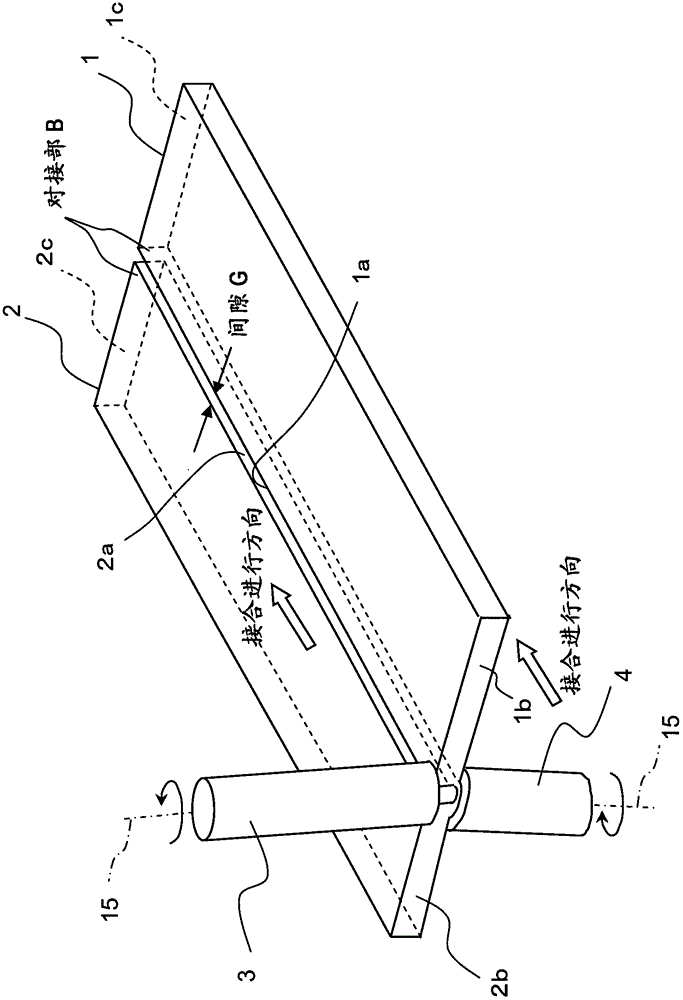

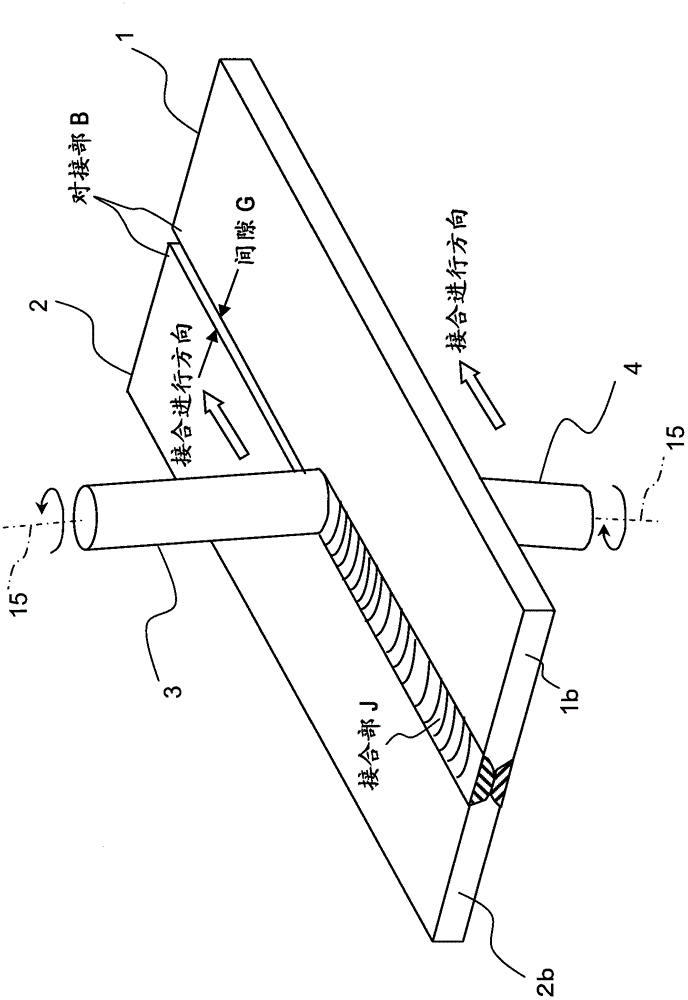

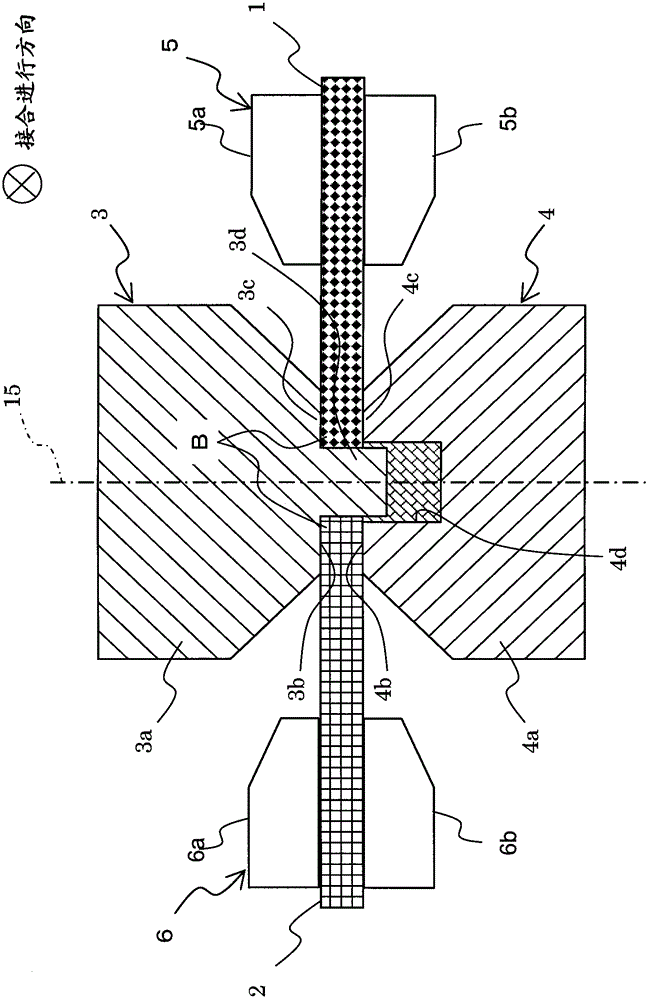

[0115] First, use Figure 1 to Figure 9 A first embodiment of the present invention will be described. This embodiment is an embodiment in which the present invention is applied to joining of two metal plates having the same plate thickness.

[0116] Figure 1 to Figure 5 is a diagram showing a double-sided friction stir welding method according to the first embodiment of the present invention, figure 1 It is a perspective view of the state after the joining start, figure 2 It is a perspective view of the joining state, image 3 is a cross-sectional view perpendicular to the tool movement direction in the state of joining, Figure 4 It is a cross-sectional view in a direction perpendicular to the tool moving direction in a joined state where the cross-sectional positions of the metal plate and the rotary tool are shifted, Figure 5 It is a cross-sectional view showing the dimensional relationship between the first and second rotary tools.

[0117] like figure 1 as wel...

no. 2 approach

[0187] Next, a second embodiment of the present invention will be described. This embodiment is an embodiment in which the present invention is applied to the joining of two metal plates having different plate thicknesses.

[0188] Figure 10 It is a figure which shows the double-sided friction stir welding method of the 2nd Embodiment of this invention, and is the state in which it is joining image 3 Sectional view at right angles to the same tool movement direction. In the figure, for image 3 The same components are provided with the same reference numerals.

[0189] Figure 10 Among them, the two metal plates 1 and 2 have different thicknesses, and a level difference is formed at the butt joint B. First, a case where the shaft centers 15 of the first and second rotary tools 3 and 4 are not inclined will be described.

[0190]When two metal plates having different thicknesses are subjected to friction stir welding simultaneously from both sides according to the prese...

Embodiment 1

[0197] (The inclination angle of the tool moving direction is the same up and down)

[0198] Metal plate 1 (5052 aluminum alloy with a plate thickness of 1 mm) and metal plate 2 (5052 aluminum alloy with a plate thickness of 2 mm) were butt-jointed. The positional relationship between the first and second rotary tools 3, 4 and the metal plates 1, 2 in Embodiment 1 is as follows Figure 11 shown. Figure 11 It is a cross-sectional view of the tool movement direction in the state of joining. Cross-sectional view perpendicular to the direction of tool movement in the state of joining, and the above-mentioned case where the rotating tool is not tilted Figure 10 same. The metal plates 1 and 2 are installed so that no step occurs on the back surface of the butt portion B. As shown in FIG.

[0199] The dimensions of the first and second rotary tools used in the confirmation test are as follows. The diameter of the shoulder surface 3 b of the first rotary tool 3 is 8 mm, the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com