Pearl white paint spraying process for vehicle bumpers

A technology of automobile bumper and pearl white, which is applied in the direction of pretreatment surface, coating, and the device for coating liquid on the surface, etc., which can solve the problems such as unsatisfactory orange peel effect, unqualified, and fading of product paint color, etc., to achieve Effects of reducing paint film orange peel defects, reducing settlement, and increasing paint film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

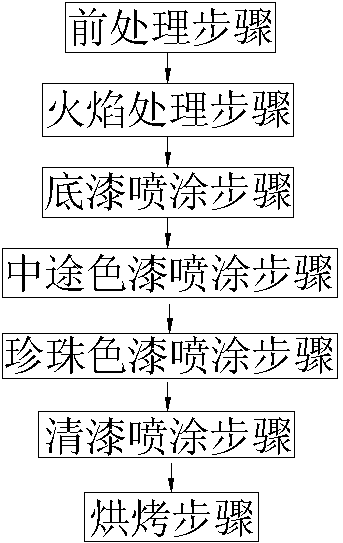

[0021] Please refer to figure 1 , the embodiment of the present invention automobile bumper pearl white painting technique, comprises the following steps successively:

[0022] Pretreatment steps: Spray with an acid cleaning agent with a total acidity value of 4 for 3 minutes; (the model of the acid cleaning agent is PP1, and the manufacturer is Shanghai Chemetall);

[0023] Flame treatment steps: Treat the surface of the car bumper with oxygen-enriched flame to make the surface tension reach more than 40 dynes;

[0024] Primer spraying steps: Use ABB air spray gun robot to spray conductive primer on the surface of the car bumper, so that the dry film thickness reaches 4-6 microns, leveling for 3 minutes; (primer model is R606G100D, the manufacturer is Tianjin PPG paint company) ;

[0025] Spraying steps of intermediate color paint: use ABB electrostatic rotary cup robot to spray the intermediate color paint once; all the thinners in the intermediate color paint are quick-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com