A power control box for an electric drive vehicle

A power control and control box technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of scattered module layout, inconvenient maintenance, and increased vehicle weight, and achieve high module integration and occupation. Less space and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

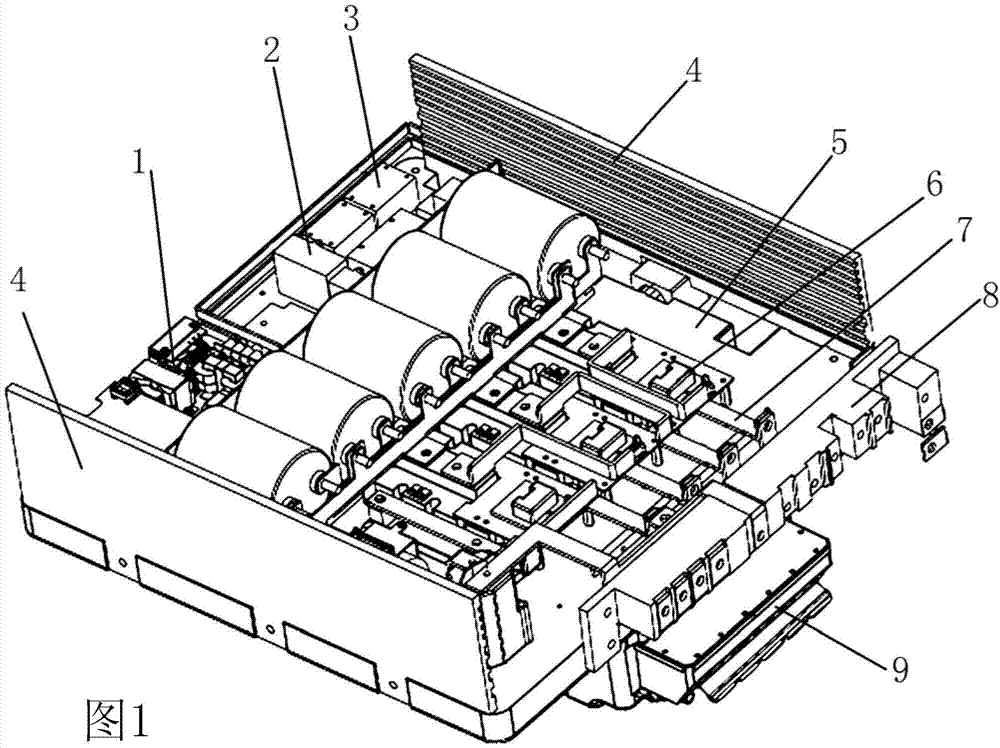

[0008] Embodiment 1: refer to figure 1 . A power control box for an electric drive vehicle, comprising a control box body and a cooling substrate 5, the inner bottom of the control box body is provided with a cooling substrate 5, and a motor controller module 6 and an air pump control module are respectively integrated on the inner cooling substrate 5 of the control box body 3. Steering pump control module 2, DC / DC module 1, the side of the control box body is provided with a connecting boss 8, the motor controller module 6, air pump control module 3, steering pump control module 2, and DC / DC module 1 through several The copper bar 7 is connected with the connecting boss 8, and the control box body below the connecting boss 8 is provided with a generator control module 9 outside. Insulating plates 4 are provided on both sides of the cooling base plate 5 in the control box body. The outer surface of the copper bar 7 is galvanized (or silver) to prevent the copper bar 7 from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com