Lapper roller lifting trolley

A technology of a rolling machine and a trolley, which is applied to the crane, crane, transportation and packaging of the trolley, can solve the problems of high labor intensity, equipment safety accidents, and low safety factor, and achieves lightening labor intensity, convenient use, and personal protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

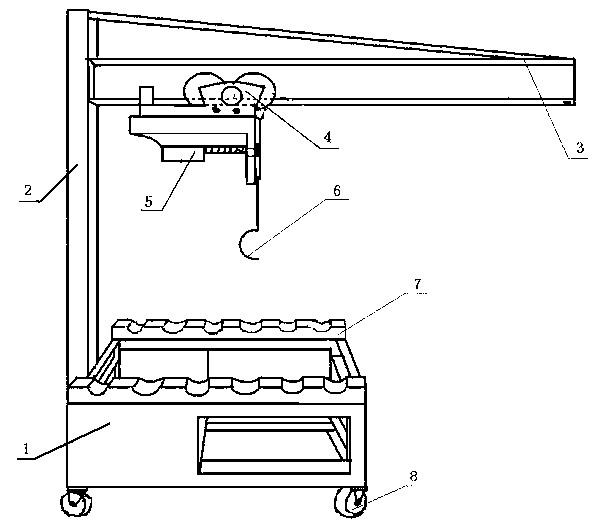

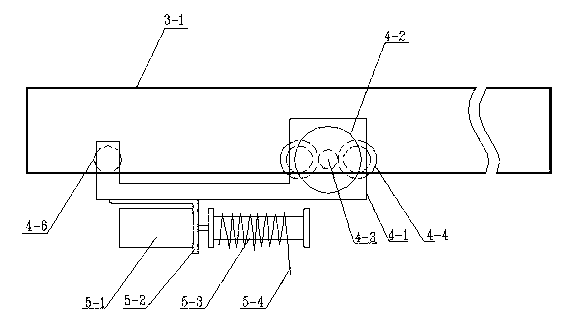

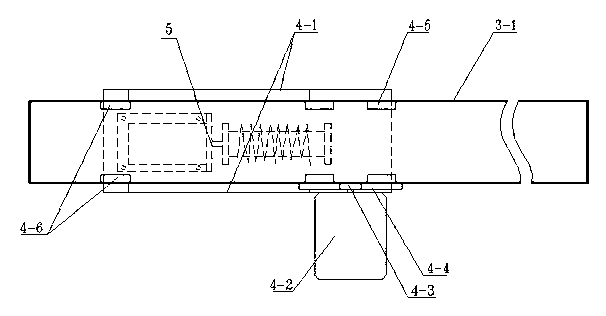

[0021] see Figure 1-Figure 5 , an embodiment of the present invention for hoisting a rolling machine roller trolley, comprising a frame 1 and a roller lifting device on the frame 1. The roller hoisting device includes a vertical frame 2, a cantilever frame 3, a traverse mechanism 4, a lifting mechanism 5, a hook 6, and a roller frame 7. The roller frame 7 is arranged on the vehicle frame 1, the vertical frame 2 is arranged on one end of the vehicle frame 1, the cantilever frame 3 is installed on the top of the vertical frame 2, and the traverse mechanism 4 includes rollers and supports. The rollers of the traversing mechanism 4 traverse along the cantilever frame 3, and the lifting mechanism 5 is installed on the support of the traversing mechanism 4. The lifting mechanism 5 includes a lifting motor 5-1 and a rope shaft 5-3, and the rope shaft 5 -3 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com