Process and device used for preparing ferrate salt with on-line wet chemical method

A ferrate, wet chemical technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of high cost, instability, harsh preparation conditions, etc., achieve high production efficiency, good stability, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

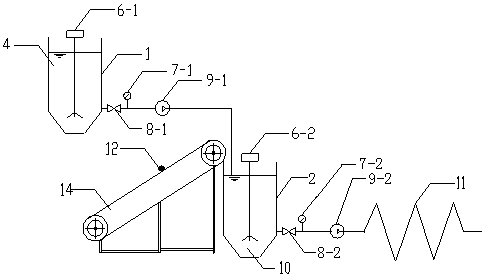

[0026] Embodiment 1: a kind of on-line wet chemical method of embodiment 1 prepares the device of ferrate, it comprises the first storage tank 1 with the first agitator 6-1, conveyer belt 14, has the second agitator 6-2 The second storage tank 2 and the annular pipe 11, the liquid outlet of the first storage tank 1 passes through the pipeline and the first valve 8-1 and the first metering pump 9-1 arranged on the pipeline and the top of the second storage tank 2 The outlet of the conveyor belt 14 is connected to the top of the second storage tank 2, and the liquid outlet of the second storage tank 2 passes through the pipeline and the second valve 8-2 and the second metering pump 9-2 provided on the pipeline. It communicates with the liquid inlet of the annular pipe 11.

Embodiment 2

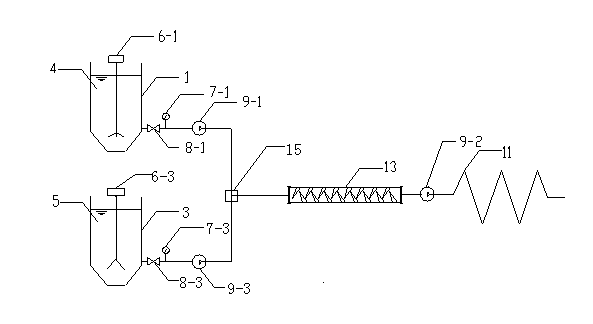

[0027] Embodiment 2: a kind of online wet chemical method of embodiment 2 prepares the device of ferrate, it comprises the first storage tank 1 with the first agitator 6-1, the 3rd storage tank with the 3rd agitator 6-3 Tank 3, static mixer 13 and annular pipe 11, the liquid outlet of the first storage tank 1 passes through the pipeline and the first valve 8-1 and the first metering pump 9-1 arranged on the pipeline, the third storage tank The liquid outlet of the tank 3 is communicated with the liquid inlet of the static mixer 13 through the three-way pipeline 15 through the third valve 8-3 and the third metering pump 9-3 arranged on the pipeline and the pipeline, and the liquid of the static mixer 13 The outlet communicates with the liquid inlet of the annular pipe 11 through the pipeline and the second metering pump 9-2 provided on the pipeline.

Embodiment 3

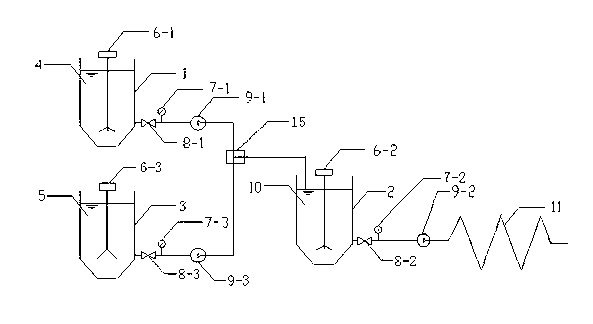

[0028] Embodiment 3: a kind of online wet chemical method of embodiment 3 prepares the device of ferrate, it comprises the first storage tank 1 that has the first agitator 6-1, has the 3rd storage tank 6-3 of the 3rd agitator Tank 3, the second storage tank 2 with the second agitator 6-2 and the annular pipe 11, the liquid outlet of the first storage tank 1 passes through the pipeline and the first valve 8-1 and the first metering valve provided on the pipeline Pump 9-1, the liquid outlet of the third storage tank 3 passes through the pipeline and the third valve 8-3 provided on the pipeline and the third metering pump 9-3 all pass through the three-way pipeline 15 and have the second agitator 6-2, the top of the second storage tank 2 is connected, and the liquid outlet of the second storage tank 2 passes through the pipeline and the second valve 8-2 set on the pipeline and the second metering pump 9-2 and the ring pipe 11. The liquid inlet is connected.

[0029] The device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com