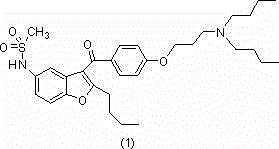

Method for producing dronedarone hydrochloride

A technology of dronedarone hydrochloride and dronedarone, which is applied in the field of medicine, can solve problems such as difficult control, easy stratification, and low yield, and achieve the effects of reducing energy consumption, simple operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Under stirring at 20°C, dissolve 9.5kg dronedarone in 28L ethyl acetate, stir for 30min until dissolved, filter, add 3.1kg 33% ethanol hydrochloric acid solution dropwise to the filtrate (volume of ethanol is about 2.5L, HCl 1.6 equivalent) , after stirring for 1 hour, a solid was precipitated, filtered, the filter cake was recrystallized with acetone, filtered with suction, washed with acetone, dried in vacuum, and crushed to obtain 9.05 kg of white solid powder (mass yield 95.3%).

Embodiment 2

[0035] Under stirring at 20°C, dissolve 9.5kg dronedarone in 28L ethyl acetate, stir for 30min until dissolved, filter, add 3.1kg 33% ethanol hydrochloric acid solution dropwise to the filtrate (volume of ethanol is about 2.5L, HCl 1.6 equivalent) , after stirring for 1 h, a solid precipitated, filtered, washed the filter cake with acetone, dried the obtained product in vacuum, and pulverized to obtain 9.4 kg of white solid powder (mass yield 99.3%).

Embodiment 3

[0037]Under stirring at 25°C, dissolve 9.5kg dronedarone in 28L ethyl acetate, stir for 30min until dissolved, filter, add 6.4kg 20% ethanol hydrochloric acid solution dropwise to the filtrate (ethanol volume is about 6.3L, HCl 2 equivalent) , after stirring for 1 hour, a solid was precipitated, filtered, the filter cake was recrystallized with acetone, filtered with suction, washed with acetone, dried in vacuum, and crushed to obtain 8.69kg of white solid powder (mass yield 91.4%).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap