Combined spiral tower tray for gas washing tower, gas cleaning device and application thereof

A coal gas washing and spiral technology, applied in the field of coal gasification, can solve the problems of easy wear, low removal rate of fine dust particles, short working cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific embodiments of the present invention are provided below. Those skilled in the art should understand that the embodiments herein are for illustrative purposes only and should not be construed as limiting the scope of the present invention defined by the claims in any way.

[0051] Therefore, in a specific embodiment, the present invention provides a combined spiral tray for a high-efficiency washing and purification process of coal gas.

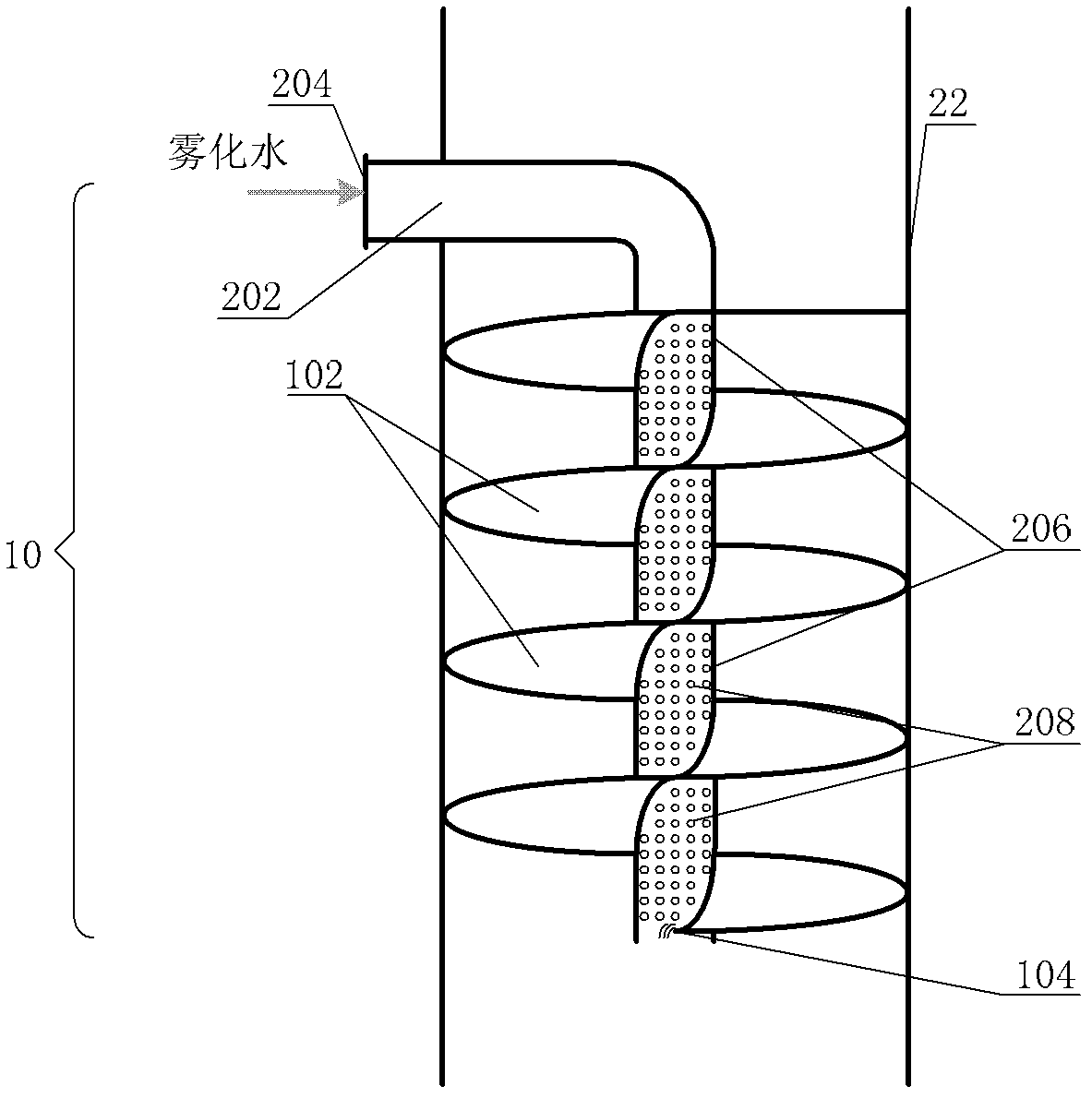

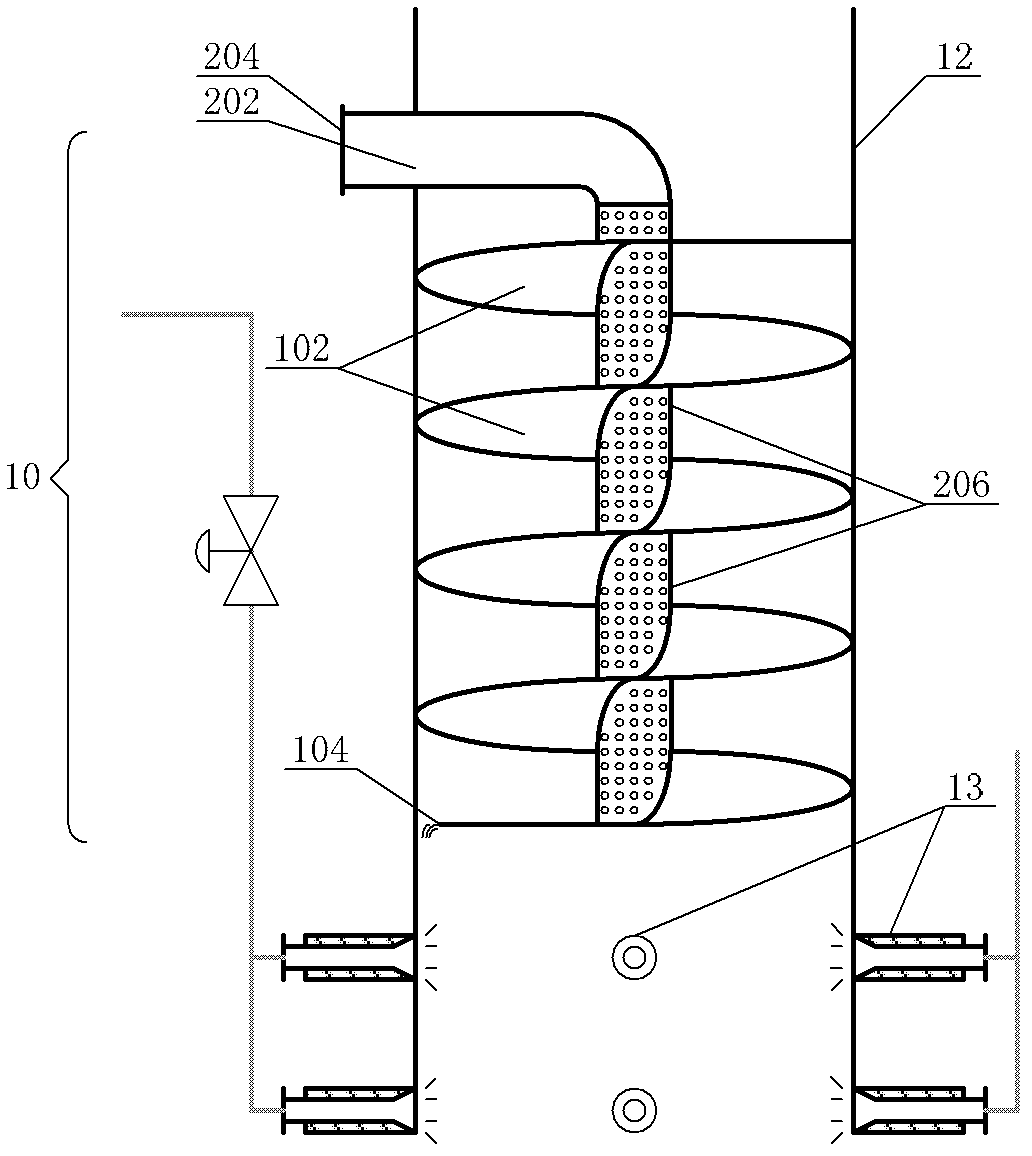

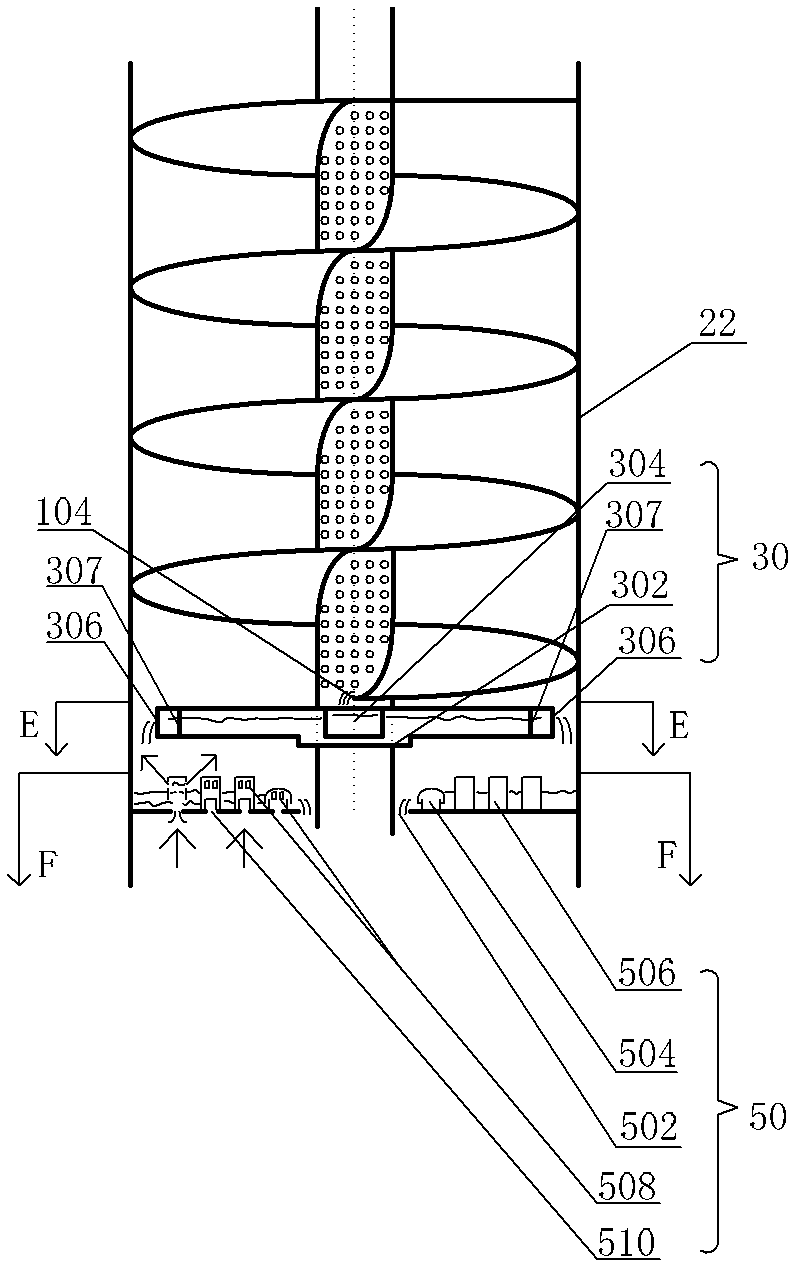

[0052] In a specific embodiment, the present invention provides a kind of circumferential spiral tray 10 for gas scrubber 1,2, it is characterized in that, comprises:

[0053] The spray column inlet pipe 202 is arranged on the upper side of the gas scrubber 1, 2 and is basically perpendicular to the tower walls 12, 22 of the gas scrubber 1, 2, and the spray column inlet pipe 202 further includes Spray column inlet 204 outside the tower wall;

[0054] Spray column 206, which is substantially vertically connected with the spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com