A rh vacuum powder spraying refining device and powder spraying method thereof

A refining device and powder spraying technology, applied in the field of refining outside the molten steel furnace, can solve the problems of high operation difficulty, maintenance difficulty and short service life of the spray gun, and achieve the improvement of powder spraying effect, powder spraying efficiency and purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

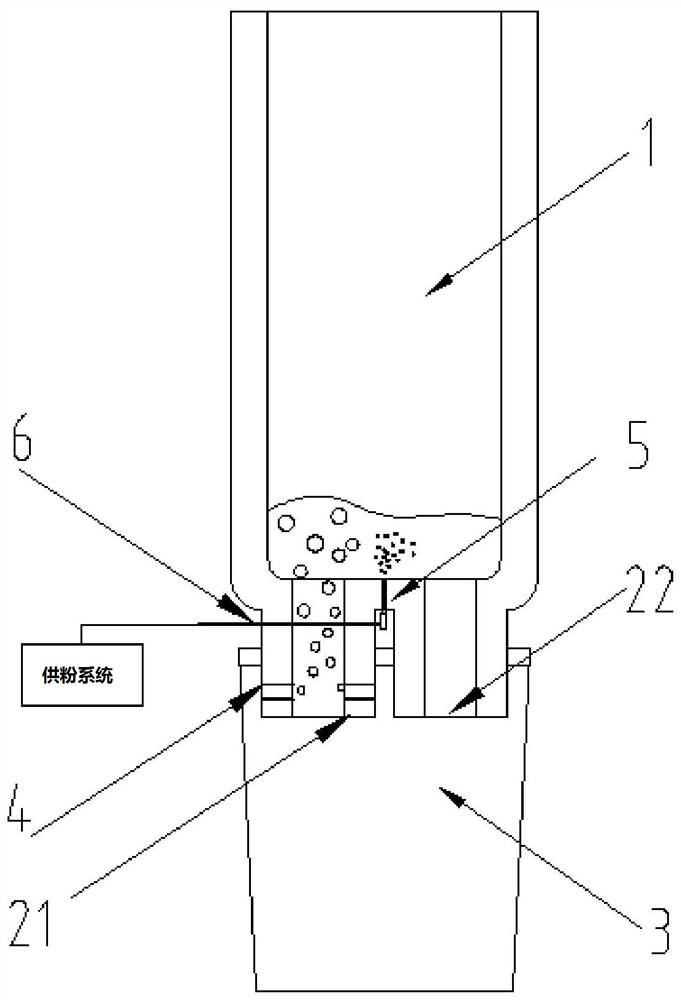

[0051] Such as Figure 5-7 As shown, the present invention is used for vacuum refining and powder spraying desulfurization of molten steel, and the device includes: a vacuum chamber 1, a ladle 3, a powder spraying element 5, a buffer gas chamber 7, a quick connection part 8, a rising pipe 21, a descending pipe 22, and a lifting gas pipeline 4 etc.

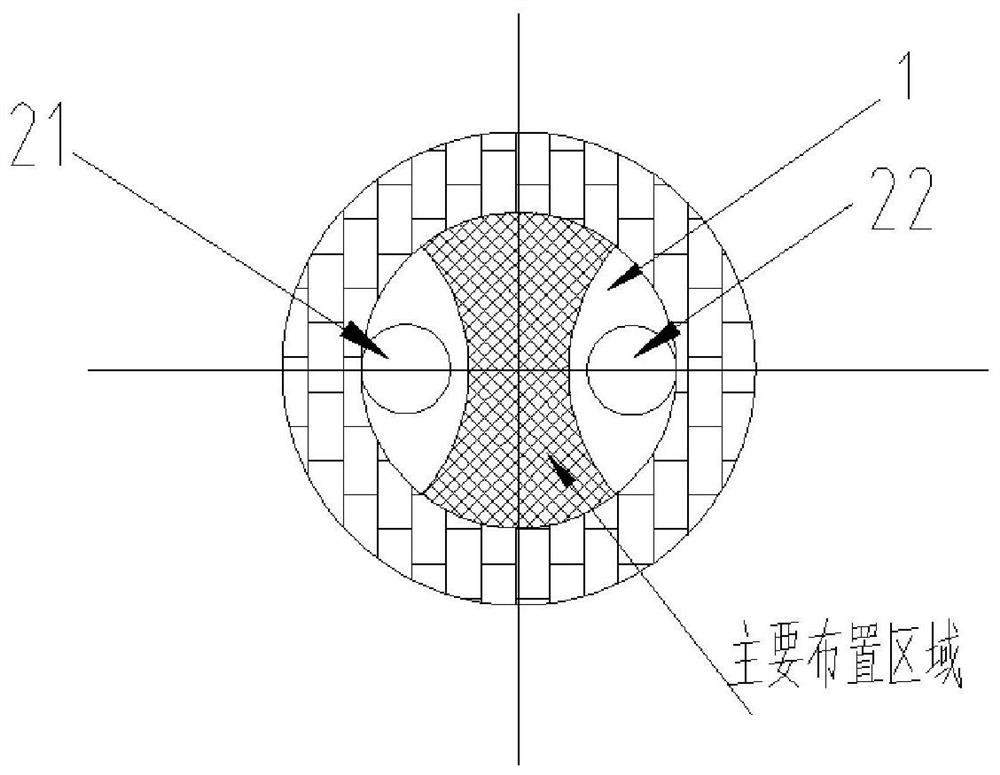

[0052] The inner diameter of the RH dipping tube is 550m, and the inner diameter of the vacuum chamber is 1860mm. The powder spraying element is in the form of a steel pipe, built into the bottom of the vacuum chamber, see Figure 5 , the quantity is 2 pieces. The arrangement position is close to the upper and lower sides of the vacuum chamber near the rising legs. The molten steel near the upper opening of the riser is violently tumbling, and the arrangement near this area can make the desulfurization powder fully contact and react with the molten steel, and also prolong the residence time of the powder in the vacuum chamber to...

Embodiment 2

[0066] Such as Figure 8-9 As shown, the vacuum refining powder spraying desulfurization device for molten steel of the present invention comprises: a vacuum chamber 1, a ladle 3, a powder spraying element 5, a buffer gas chamber 7, a quick connection part 8, a rising pipe 21, a descending pipe 22, a lifting gas pipeline 4, etc. .

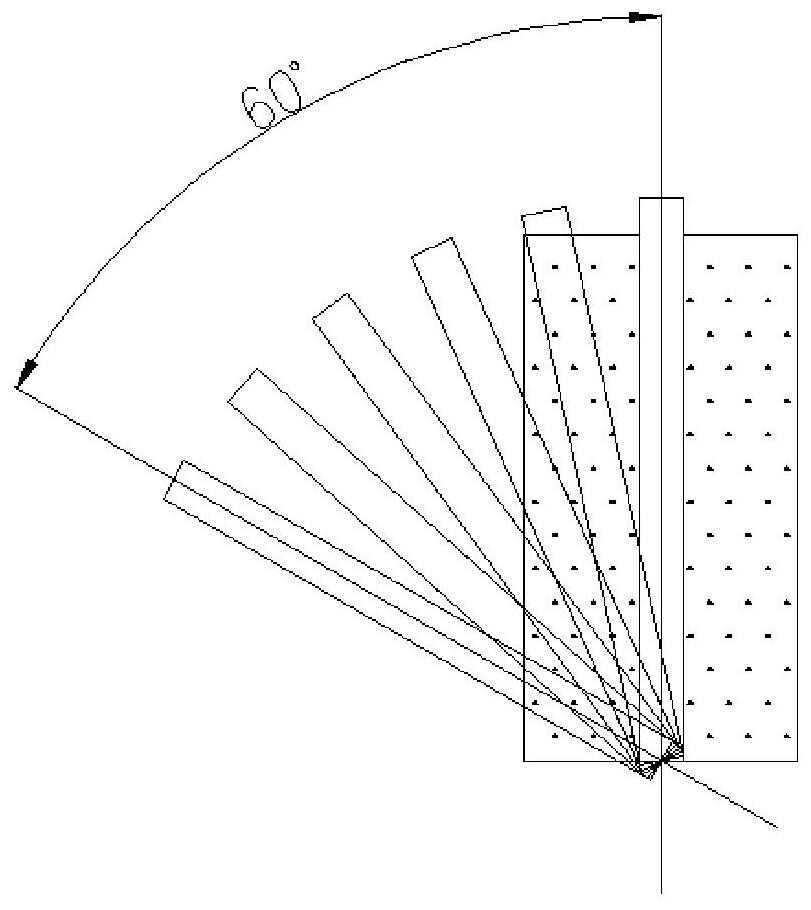

[0067] The inner diameter of the RH dipping tube is 550m, and the inner diameter of the vacuum chamber is 1860mm. The powder spraying element is in the form of a steel pipe, built into the bottom of the vacuum chamber, see Figure 8 , the quantity is 4 pieces. The vertical inclination angle of the nozzle is 20 degrees, see Figure 9 . In the figure, the nozzles all point to the upper center of the rising leg, and the horizontal angles between the nozzles and the center line of the lifting pipe are 15 degrees and 50 degrees respectively.

[0068] The four nozzles are evenly arranged in the steel flow moving from the riser to the downcomer, and ...

Embodiment 3

[0081] Such as Figure 10-11 As shown, the molten steel vacuum refining alloy powder spraying device of the present invention comprises: a vacuum chamber 1, a ladle 3, a powder spraying element 5, a buffer gas chamber 7, a quick connection part 8, a rising pipe 21, a descending pipe 22, and a lifting gas pipeline 4 Wait.

[0082] The inner diameter of the RH dipping tube is 550m, and the inner diameter of the vacuum chamber is 1860mm. The powder spraying element is in the form of a steel pipe, built into the bottom of the vacuum chamber, see Figure 10 , the quantity is 2 pieces. The vertical inclination angle of the nozzle is 15 degrees, see Figure 9 . Both tend to descend toward the center of the leg.

[0083] After the alloy powder is sprayed through the nozzle, it is rapidly melted in the molten steel, and quickly participates in the circulation flow with the molten steel to complete the homogenization of the alloy composition as soon as possible. The inner diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com