Monolithic rail bed and turnout lifting support arrangement structure of subway short sleeper

A technology of integral ballast bed and layout structure, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of difficult control of the height of buttresses and long construction period, and achieve the effect of improving construction quality, easy control and operation, and improving project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

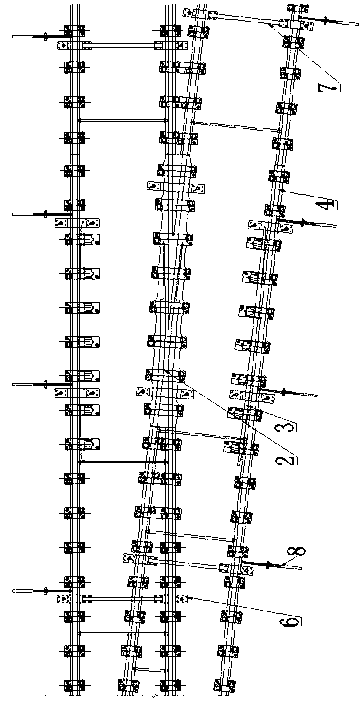

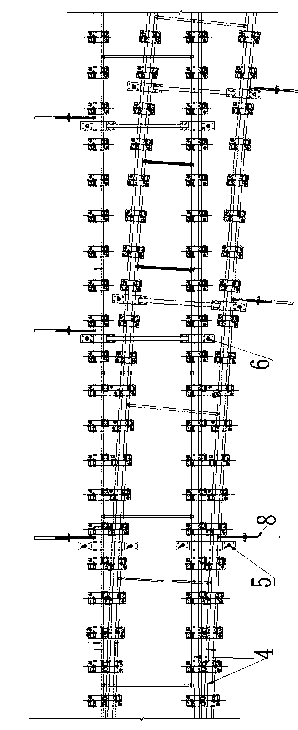

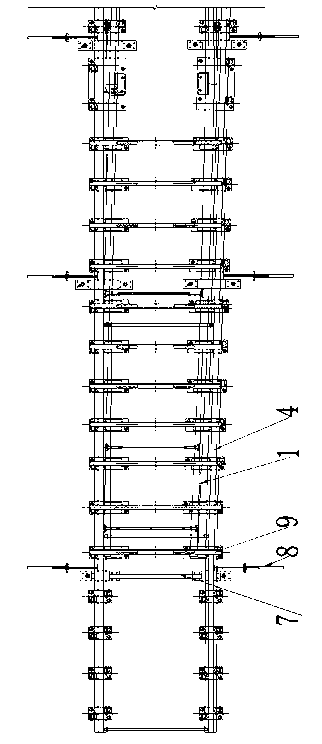

[0024] Embodiment: Take the construction of the short sleeper integral ballast bed of a single turnout in a certain subway as an example. According to the structure of the track bed of the turnout, three kinds of lifting brackets are designed: special lifting brackets are set up under the steel rail of the overlapping section of the point rail 1 and the track 4 of the turnout, below the frog 2, and under the overlapping section of the guard rail 3 and the track 4 Bracket 5, elevated track support 6 is set under the rails of the intersection section of the two tracks between tip rail 1 and frog 2, and main line track support 7 is set under the rails of the tracks other than tip rail 1 and frog 2. A total of 7 sets of mainline lifting brackets, 6 sets of elevated lifting brackets, 12 sets of special lifting brackets, and 26 sets of track screw rods need to be installed.

[0025] Both sides of the supporting plate 21 in the middle of the special road support 5 are equipped with n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com