Assembly type bounding wall

A prefabricated, fence technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of easy cracking of masonry walls, difficult construction, long construction period, etc., to solve winter construction problems, shorten construction period, and simple assembly quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

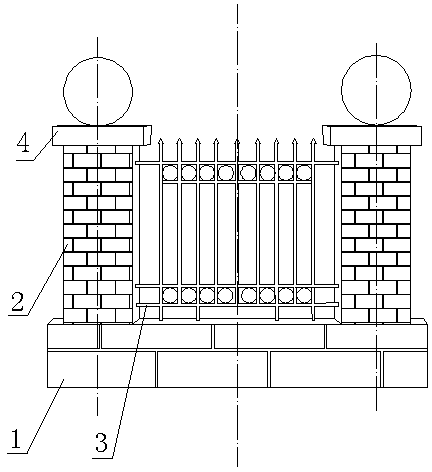

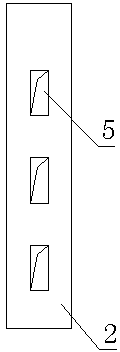

[0023] Such as figure 1 As shown, the prefabricated wall of the wrought iron wallboard is mainly composed of the components of the column body 2 and the wrought iron wall panel 3, and the column body 2 and the wall panel 3 components are assembled on site to form the wall. Cylinder 2 side has jack 5 (as image 3 shown), the wrought iron wallboard 3 is connected and fixed to the column body 2 through the jack 5. A column cap 4 is arranged above the column body 2 . A foundation 1 is arranged between the column body 2 and the ground for reinforcement, and the bottom of the wrought iron wallboard is inserted into the foundation 1 . The connection between the column body 2 and the foundation 1 can be fixed through the pre-embedded connecting steel bar 7 (such as Figure 5 shown). or use Figure 6 The connection mode shown: the bottom of the column body 2 is equipped with a metal connecting plate 8, and the ground angle bolts 9 are pre-embedded in the foundation 1, and the grou...

Embodiment 2

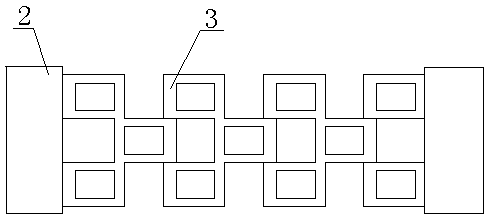

[0025] Such as figure 2 As shown, the assembled enclosure wall of the hollowed-out wall panel is mainly composed of the components of the column body 2 and the wall panel 3, and the components of the column body 2 and the wall panel 3 are assembled on site to form the enclosure wall. The side of described cylinder 2 has slot 6 (as Figure 4 shown), the wall plate 3 is connected and fixed with the column body 2 through the slot 6.

[0026] In addition, the columns and solid wall panels have decorative surfaces outside, which increases the beauty of the enclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com